Industrial Rollers

(2844 products)Industrial Roller Chain - Color: Grey

Price: 5000 INR/Piece

MOQ2 Piece/Pieces

ColorGrey

UsageCommercial and Industrial

MaterialMild Steel

SizeStandard

Product TypeIndustrial Roller Chain

Width20 Millimeter (mm)

Emco Engineering

Mumbai

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller6 Years

Guide Rollers - Premium Steel and Brass Construction | International Quality Compliance for Diverse Industrial Applications

Main Domestic MarketAll India

Hi-tech Applicator

Ahmedabad

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller18 Years

Steel Kaju Cutting Roller

Product TypeKaju Cutting Roller

ColorSilver

MaterialStainless Steel

Jackson Machine

Ahmedabad

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller Super Premium

Super Premium7 Years

Super Premium

Super PremiumTop Rated Gravity Roller

Payment TermsCash on Delivery (COD), Cash Against Delivery (CAD), Cheque

Sample AvailableYes

Sample PolicyContact us for information regarding our sample policy

Ibk Engineers Pvt. Ltd.

Bengaluru

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller Premium Seller

Premium Seller11 Years

Polypropylene Roller

Product DescriptionWe are very reputed manufacturer and supplier a revolutionary variety of Polypropylene Roller in Indore, Madhya Pradesh, India. The entire range of Polypropylene Roller is designed and manufactured using finest quality raw material and cutting-edge techniques under the visionary supervision of train

Mnt Industries

Indore

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller10 Years

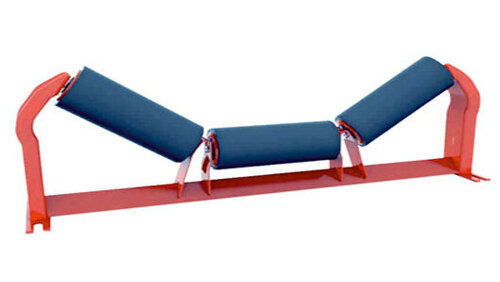

Red Self Aligning Roller

Price: 3500 INR/Unit

MOQ10 Unit/Units

ColorRed

Product TypeSelf Aligning Roller

SizeDifferent Size

UsageIndustrial

MaterialMild Steel

Shiv Dhara Fabricators And Engineering

Ahmedabad

Trusted Seller

Trusted Seller Super Seller

Super Seller3 Years

Industrial Idler Rollers - Carbon Steel, Customized Size | Galvanized Finish, Heavy Duty, Rust Free, Long Lasting Life

MaterialCarbon Steel

Product TypeIndustrial Idler Rollers

TechniqueGalvanized

Rohan Engineering Enterprise

Howrah

Trusted Seller

Trusted Seller Premium Seller

Premium Seller18 Years

Vertical Guide Roller - Color: Silver

MOQ10 Unit/Units

ColorSilver

UsageIndustrial

SizeDifferent Available

Product TypeVertical Guide Roller

MaterialMIld Steel

Delite Systems Engineering (i) Pvt. Ltd.

Mumbai

Trusted Seller

Trusted Seller Premium Seller

Premium Seller22 Years

Excavator Track Roller - Color: Silver

MOQ1 Piece/Pieces

ColorSilver

Capacity100 Kg per meter Kg

DiameterN/A Millimeter (mm)

UsageIndustrial

MaterialMild Steel

SizeCustomizable

Smt Conveyors And Automations

Bengaluru

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

High Intensity Magnetic Roller System - Premium Quality Fabrication, Efficient Iron Particle Separation for Minerals, Food, Glass, Ceramics Industries

Product DescriptionOur company is invovled in fabricating and offering a premium quality range of High Intensity Magnetic Roller System. These offered products are engineered by using finest grade raw material under the guidance of our skilled experts. This is used to separate weakly iron particle from various types

Force Magnetics

Vadodara

Trusted Seller

Trusted Seller Premium Seller

Premium Seller12 Years

Stainless Steel Guide Roller - Feature: High Quality

MOQ10 Unit/Units

UsageIndustrial

MaterialStainless Steel

SizeDifferent available

Product TypeStainless Steel Guide Roller

FeatureHigh Quality

Silver 500 Mm Polyurethane Roller

Price: 115000 INR/Square Meter

MOQ1 Square Meter/Square Meters

Length1800 Millimeter (mm)

Diameter122 Millimeter (mm)

UsageIndustrial

ColorSilver

Product TypePolyurethane Roller

SizeRollar Length - >500 Mm

Swagath Urethane Private Limited

Bhubaneswar

Trusted Seller

Trusted Seller Super Seller

Super Seller3 Years

Embossing Roller - Color: Black

Price Trend: 7000.00 - 20000.00 INR/Box

MOQ1 Roll/Rolls

UsageIndustrial

ColorBlack

Product TypeEmbossing Roller

MaterialMS, SS, Rubber

StandardHigh

FeatureHeat Resistant

Print Pack Stereo

Vadodara

Trusted Seller

Trusted Seller Premium Seller

Premium Seller7 Years

2Mm Tar Felt Roll - Color: Black

MOQ10 Roll/Rolls

UsageIndustrial

MaterialTar

TechniqueHot Rolled

ColorBlack

FeatureHigh Quality

Shankar Weldmesh Private Limited

Kolkata

Trusted Seller

Trusted Seller Premium Seller

Premium Seller1 Years

De 360 Roller Screed Paver, Usage/Application: Road Construction Work

Product DescriptionDe 360 Roller Screed Paver

Sana Diamond Engi-mech Llp

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller4 Years

Industrial PU Rollers

Price Trend: 5000.00 - 25000.00 INR/Piece

MOQ100 Piece/Pieces

DiameterAvailable from 50 mm to 500 mm

CapacityUp to 5 Tons

MaterialPolyurethane (PU)

DimensionsAs per customer requirement

TechniquePrecision Molded, Hot Casted

StandardIS: 8531

Shreeram Polyplast

Chennai

Trusted Seller

Trusted Seller Premium Seller

Premium Seller12 Years

0.8Mm Wire Feeder Roller - Color: Silver

MOQ100 Unit/Units

UsageIndustrial

MaterialMetal

SizeDifferent Size

Product TypeFeeder Roller

Dimensions0.8 Millimeter (mm)

ColorSilver

Arcweld Engineers Pvt Ltd

Mumbai

Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

High Strength Nylon Roller Belt Width: 80 Millimeter (Mm)

Price: 160/Piece

MOQ4 , Piece/Pieces

StandardPu roller

Belt Width80 Millimeter (mm)

A One Caster

Bharuch

Premium Seller

Premium Seller5 Years

Cylinder Engraving Base - Color: Silver

MOQ1 Piece/Pieces

SizeStandard

ColorSilver

UsageIndustrial

Product TypeCylinder Engraving Base

MaterialMild Steel

FeatureGood quality & durable

J. M. D. Industries

Bahadurgarh

Trusted Seller

Trusted Seller Premium Seller

Premium Seller14 Years

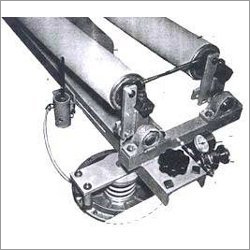

Light Duty Tyre Cord Centralizer

Price Trend: 125000.00 - 425000.00 INR/Set

MOQ1 Set/Sets,

CapacityLight Duty

DiameterUp to 100 mm

MaterialTyre Cord

DimensionsCompact Design

TechniqueCentralizing Mechanism

StandardIndustrial Standards

Belmark Industries

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller16 Years

Single Horizontal Roller Buffer - Color: Black

Price: 225 INR/Piece

MOQ200 Piece/Pieces

SizeStandard

UsageIndustrial

ColorBlack

Product TypeSingle Horizontal Roller Buffer

MaterialRubber

StandardYes

Pvh Industries

Sonipat

Trusted Seller

Trusted Seller Super Seller

Super Seller23 Years

Baling Machine - Color: Green

Price: 350000 INR/Piece

MOQ1 Piece/Pieces

UsageIndustrial

ColorGreen

Product TypeBaling Machine

MaterialMS

Aline Conveyors Private Limited

Ghaziabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller11 Years

Grey Anilox Roll

MOQ1 Unit/Units

CapacityOptimized for High Volume Printing

DiameterVarious Options Available

UsageIndustrial

MaterialMetal

SizeDifferent Size

DimensionsDifferent Size

Imagegravures

Gandhinagar

Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

SiC Roller - Dia. 27-70mm, Length 1000-5000mm | Exceptional Durability, Heat Resistance, Superior Mechanical Strength

Price: 30 USD ($)/Piece

MOQ10 Piece/Pieces

DiameterDia.27-70 Millimeter (mm)

UsageSupport in the kiln

MaterialSIC

SizeDia.27-70mm

Product TypeSintered Silicon Carbide Roller

DimensionsOD.27-70mm Millimeter (mm)

Firller Industry Technology Co.,ltd.

Shenzhen

Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

Five Sheave Roller - Stainless Steel, Custom Size Available | First-Class Quality for Industrial Heavy-Duty Lifting & Material Handling

Price: 42000 INR/Unit

MOQ10 Unit/Units

UsageIndustrial

MaterialStainless Steel

SizeAs Per Requirement

StandardFirst Class

FeatureHigh Quality

Precisetech India Private Limited

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

Industrial Hard Chrome Roller - Feature: High Quality

Price: 35000 INR/Piece

MOQ10 Piece/Pieces

UsageIndustrial

SizeVarious Sizes Available

Length500 mm-3000 mm Millimeter (mm)

MaterialStainless Steel

TechniqueHot Rolled

FeatureHigh Quality

Indon Engineering Works

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller1 Years

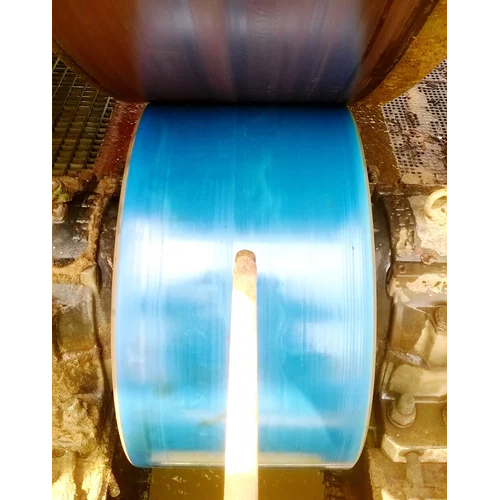

Industrial Roller With Frame - Rubber, 60-200 Millimeter Diameter, 3-4 Inch Length, Blue Color | Durable, Ideal for Printing, Packaging, Material Handling

Price: 3500 INR/Unit

MOQ1 Unit/Units

Length3-4 Inch (in)

ColorBlue

SizeStandard

UsageIndustrial

Diameter60-200 Millimeter (mm)

MaterialRubber

Mm Despro Engineering Pvt. Ltd.

Delhi

Trusted Seller

Trusted Seller Premium Seller

Premium Seller1 Years

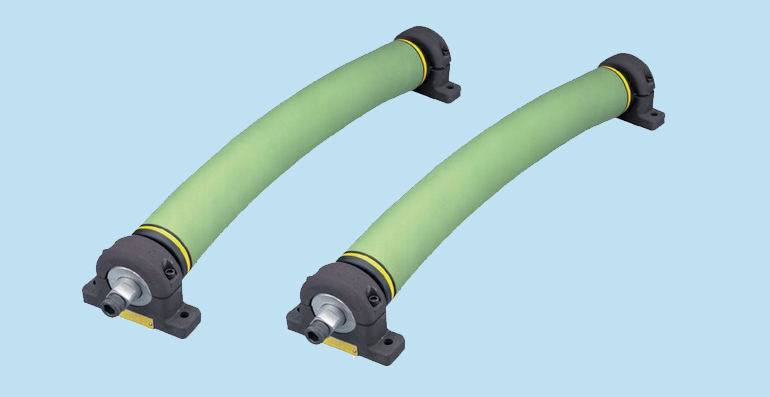

Industrial Bow Roller - Color: Grey & Black

MOQ10 Piece/Pieces

ColorGrey & Black

UsageIndustrial

SizeAs per required

MaterialRubber

StandardHigh

FeatureEasy to use

Grs Webtech

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller1 Years

Latest From Industrial Rollers

Popular Industrial Rollers

Introductions to Industrial Rollers

Industrial rollers are robust machine elements that are manufactured by using advanced production methods that give high dimensional accuracy and uniformity throughout their length. These heavy-duty machine parts are available in different types as per the applications where they are going to be installed. The offered rollers can be used in printing, manufacturing, material handling, winding & rewinding, packaging, and more. They are manufactured by using top-quality materials such as mild steel, stainless steel, and cast iron that give high strength and rigidity to resist loads and vibrations during operation. The protruding cylindrical ends of these machine spares make it easier to install them within plumber blocks to ensure smooth rotation. Industrial Rollers come in many different lengths and diameters as per the machines in which they are going to be installed.

Rollers for a Diverse Range of Industries

Industrial Machine rollers can be used in a wide range of industrial applications. Given below are some of the common industrial sectors where heavy-duty rollers are used:

-Manufacturing: In small to large-scale manufacturing facilities it is required to move various types of products along the assembly lines, this can be achieved with the help of roller conveyors.

-Printing: Highly finished steel rollers are used in industrial printing machines for efficient ink transfer on substrate sheets for quick printing.

-Inventory Management: Machines such as roller conveyors, gravity flow racks, and other material handling machines require steel rollers for the efficient transportation of goods.

-Farming Equipment: Rollers can also be used in agricultural machines for the cleaning, classification, and sorting of various types of raw food products.

-Dyeing: Heavy-duty machines such as textile printers and dyeing machines are equipped with steel rollers for the efficient transfer of colorants on various types of fabrics.

Industrial rollers for the Textile Industry

Industrial Rollers play an important role in various textile machines such as fabric printers, textile processing, and many more. They are designed to ensure smooth operation which ultimately leads to high productivity. There are many different heavy-duty rollers availed by our company which include squeezing rollers, spreader rollers, guide rollers, and many more. The offered textile rollers make it easier to efficiently perform various operations which include weaving, spinning, and finishing. They are made up of premium-grade materials such as aluminum, stainless steel, and high-density thermoplastic that give high strength and rigidity. The curved surfaces of textile rollers are treated with a smooth coating that greatly eliminates the risk of tearing fabric at high speeds. Rollers used in textile machines show excellent resistance against contaminations and can be easily cleaned.

Industrial Rollers for the Metal Foil Industry

Industrial rollers for metal foil manufacturing machines make it easier and more productive to produce metal foils in various sizes and thicknesses. These heavy-duty machine elements are typically manufactured by using stainless steel and alloys that give high rigidity with excellent anti-wearing properties. There is a wide variety of these top-grade textile rollers available in the market which include work rollers, slitters, bridle rollers, winding rollers, and more. These specialized rollers are machined with the help of advanced CNC machines to make them free from sharp edges, uneven surface finish, and other manufacturing flaws. Industrial rollers greatly improve production capacity as well as eliminate the risk of damage to raw materials.

Industrial rollers for the Printing/Packaging Industry

There are many different types of heavy-duty rollers that can be used in the printing and packaging industries for efficient and streamlined production. Some of the most popular types of rollers that can be used in the printing and packaging sectors are:

-Feed Rollers: They are used to grab and feed the substrate materials such as paper, films, foils, and fabric into the machine with controlled speed and positional accuracy.

-Inking Rollers: These specialized machine rollers are designed to transfer inks from the supply source to printing plates to ensure efficient and smudge-proof printing.

-Impression Rollers: The purpose of these types of rollers is to apply pressure on substrates and printing plates for sharp and clean printing.

-Laminating Rollers: In packaging industries, it is required to make a fine layer over products for efficient and quick packaging, this is done with the help of specialized laminating rollers.

-Material Handling Rollers: They are commonly used within heavy-duty conveyor machines to move heavy objects at desired speed without a labor force.

Top Industrial Roller Manufacturers in India.

Given below is the list of some of the renowned Industrial roller manufacturers in India:

Hi-tech Applicator: It is a Gujarat, India-based manufacturer, supplier, and exporter of heavy-duty rollers. The offered rollers can be delivered to our clients in various customized sizes.

Natraj Corrugating Machinery Company: Established in the year 1970, this leading firm deals in manufacturing and supplying best-in-class rollers that are made up of top-grade materials such as alloyed steel, aluminum, rubber, thermoplastics, and various other materials.

Hri Engineering Company We are offering top-grade that can be used in textile, printing, metal foil production, and various other applications.

Gayatri Rubber & Fibre Plast Industry: This Gujarat, India-based manufacturing facility offers a wide range of sturdy and durable rollers that are manufactured by using synthetic materials such as rubbers and high-density thermoplastics.

FAQs: Industrial Roller

Q. What is an industrial roller?

Ans. Industrial Roller is a sturdy machine element that can be used for various purposes such as material moving, raw material processing, textile printing, lamination, and many more. This machine spare is designed and developed by using advanced production methods and top-grade alloyed materials that lead to flawless design and high rigidity. The offered roller is designed to withstand heavy loads, vibrations, high temperatures, and corrosion. It comes in various customized sizes according to the machine in which it is going to be installed. The high load-bearing capacity, rust resistance, and versatility make it highly demanded among our customers and various industrial operations. It can also be used in recycling machines, metal foil production, and paper printing. Roller for industrial machines greatly improves the efficiency and production capacity of machines.

Q. What are the types of industrial rollers?

Ans. There are many different types of light to heavy-duty Industrial Rollers available in the market that can be used in various industrial sectors and machines. The most common types of rollers are:

-Idler Rollers: Made up of high-density rubber and polyurethane these premium-grade machine components are designed to guide and support conveyor belts.

-Conveyor Rollers: They are specially designed for material handling machines to safely move various types of products within industrial facilities. Top-grade engineering materials such as steel and aluminum are used for the fabrication of these rollers to impart high rigidity and strength.

-Drive Rollers: These types of rolling elements are commonly used within the transmission system of various industrial machines to efficiently transfer rotational power with the help of a belt or chain drive mechanism.

-Printing Rollers: Printing rollers are in high demand within industrial-class printing machines to make high-quality prints on various types of materials such as paper, fabric, plastic film, and many more.

Q. How industrial rollers are made?

Ans. Industrial Rollers are sturdy cylindrical-shaped machine components that are commonly used in heavy-duty machines such as conveyors, textile printers, and many more. These highly finished metallic units are fabricated by using advanced machining technologies that give high dimensional accuracy and a smoother surface finish. There are various steps involved in manufacturing various types of industrial rollers:

Selection of Raw Materials: The very first step is to choose materials as per the types of machines for which rollers are required. There are various types of materials such as steel, high-density plastic, rubber, stainless steel, and aluminum are commonly used for the fabrication of rollers.

-Machining: The selected raw material is then machined with the help of advanced CNC machining technologies to achieve desired diameter and length with precision.

-Heat Treatment: To enhance the internal strength of machined rollers they are needed to undergo a heat treatment process to improve internal crystalline structure that leads to high impact strength and rigidity.

-Surface Finishing: After heat treatment, the industrial rollers are then transferred to the surface treatment section to provide a high-class finish as well as provides excellent protection against rust and corrosion.

-Quality Control: At the end, it is required to perform an inspection of the final products to determine if there are any manufacturing flaws.

Manufacturers & Suppliers of Industrial Rollers

Company Name | Member Since |

|---|---|

Pvh Industries Sonipat, India | 23 Years |

Delite Systems Engineering (I) Pvt. Ltd. Mumbai, India | 22 Years |

Hi-Tech Applicator Ahmedabad, India | 18 Years |

Rohan Engineering Enterprise Howrah, India | 18 Years |

Belmark Industries Ahmedabad, India | 16 Years |

J. M. D. Industries Bahadurgarh, India | 14 Years |

Force Magnetics Vadodara, India | 12 Years |

Shreeram Polyplast Chennai, India | 12 Years |

Ibk Engineers Pvt. Ltd. Bengaluru, India | 11 Years |

Aline Conveyors Private Limited Ghaziabad, India | 11 Years |

Popular Products