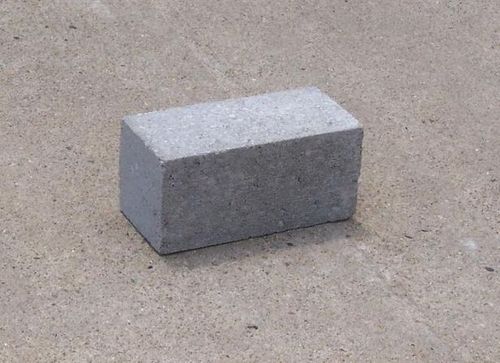

Fly Ash Brick - Fly Ash (50%), Slaked Lime (30%), Anhydrous Gypsum (20%), 230x110x75 Mm, White, 10 Mpa Compressive Strength, Autoclaved Finish

Price: 3.28 INR / Piece

Get Latest Price

In Stock

Product Specifications

| Material | Fly ash |

| Dimensions | Variable |

| Strength | 7.5-10 MPa |

| Weight | <40% clay brick |

| Specific gravity | 0.6-0.65 |

| Porosity | High |

| Color | Gray |

| Features | Lightweight, Strong, Insulating, Durable, Cost-effective, Eco-friendly, Versatile |

| Water Absorption | 5% |

| Working Life | 50 Years |

| Dimension (L*W*H) | 230*110*75 Millimeter (mm) |

| Compressive Strength | 10 Megapascals (MPa ) |

| Bricks Type | Fly-Ash Bricks |

| Type | Common Bricks |

| Size | 9 In. X 4 In. X 3 In. |

| Thickness | 75 Millimeter (mm) |

| Technics | Autoclaved |

| Payment Terms | Cash in Advance (CID), Cheque, Cash Advance (CA) |

| Supply Ability | 5000 Per Day |

| Delivery Time | 2 Days |

| Sample Policy | Free samples available with shipping and taxes paid by the buyer |

| Main Export Market(s) | Asia |

| Main Domestic Market | Rajasthan |

Product Overview

Key Features

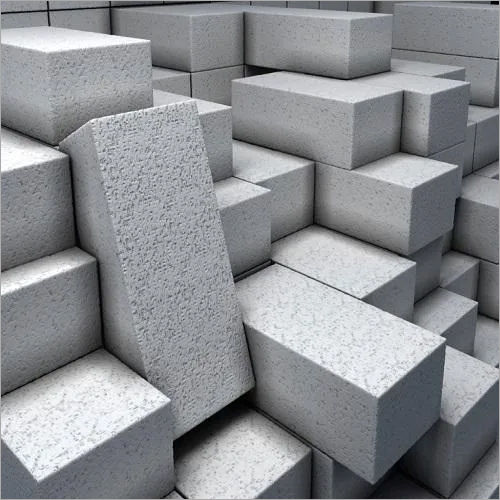

Main ingredients include fly ash, water, quicklime or lime sludge, cement, aluminum powder and gypsum. Auto-claving increases the hardness of the block by promoting quick curing of the cement. Gypsum acts as a long term strength gainer. The chemical reaction due to the aluminum paste provides AAC its distinct porous structure, lightness, and insulating properties. The aforementioned properties set it apart from other lightweight concrete materials. The finished product is a lighter block, less than 40% the weight of conventional Bricks, while providing the similar strengths. The specific gravity stays around 0.6 to 0.65. Using these blocks in buildings reduces the dead load, allowing one to save around 30 to 35%[citation needed] of structural steel, and concrete.

Commercial processes fall into two categories; the lime route, and the cement (OPC) route where the latter is used as a source of lime. In the lime route, the composition is fly ash (50%), slaked lime (30%), and anhydrous gypsum (20%), to which 3 to 4 times of stone dust, sand or any inert filler material can be added. In the cement route, the composition is fly ash(76%), OPC (20%), and anhydrite (4%), to which 3 to 4 times of filler material can be added.

The following properties of fly ash affect the strength and look of fly ash bricks.

Loss on Ignition (LOI): fly ash loses weight when it burns at about 1000 A C due to presence of carbon and water. The weight loss happens due to carbon combustion and moisture evaporation is called "Loss on Ignition(LOI)". This is expressed as percentage. The lower the loss of Ignition, the better will be fly ash. As per BIS it should not be more than 5%.[citation needed]

Fineness: fine fly ash has more surface area available to react with lime. This increases pozzolanic activity, which contributes to the strength of fly ash bricks. As per BIS it should not be more than 320 m2/kg

Calcium (CaO) content: the pozzolanic reactivity of fly ash is more in high calcium fly ash. The greater the pozzolanic activity leads to higher the strength of fly ash brick. As per ASTM C618 fly ash is classified into two types: Class C contains more than 10% lime and Class F fly ash contains less than 10% lime.[3]

Based on boiler operations, fly ash can be additionally classified as LT (low temperature) and HT (high temperature). LT fly ash containing amorphous phases is generated where boiler temperature is not more than 800 A C, whereas HT fly ash containing glassy reactive phases is generated at more than 1000 A C in super thermal plants. LT fly ash reacts well with lime whereas HT fly ash reacts well with OPC [4].

Company Details

Focusing on a customer-centric approach, MAESTRO ENGINEERS has a pan-India presence and caters to a huge consumer base throughout the country. Get Bricks from MAESTRO ENGINEERS at Trade India quality-assured services.

Business Type

Manufacturer, Service Provider, Supplier, Wholesaler, Producer

Employee Count

15

Establishment

1996

Working Days

Monday To Sunday

GST NO

08AAXFM6627Q1Z3

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 08AAXFM6627Q1Z3

Jodhpur, Rajasthan

Accepts only Domestic inquiries

Proprietor

Mr M. G. Sharma

Address

B No - 31 , Ram Mohlla, Offside Nagori Gate, Jodhpur, Rajasthan, 342001, India

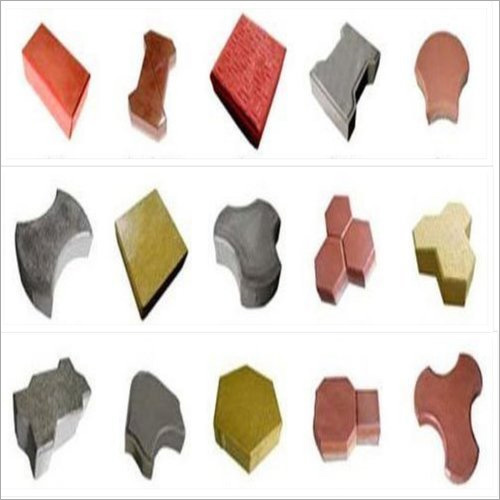

interlocking bricks in Jodhpur

Report incorrect details