- Tradeindia

- Washers

- Can Washer

Can Washer

(1245 products)Retainer Push On Fix Washers - Carbon Steel, M2 - M64 Size, Silver Color | High Tolerance, Rust Resistant, Polished Finish, Rugged Round Design

Price: 5 INR/Piece

MOQ5000 Piece/Pieces

ColorSliver

Length1-1/4 Inch (in)

Weight99.8 Grams (g)

MaterialStainless Steel

ShapeRound

Thickness3-10 Millimeter (mm)

Silver Stainless Steel Fender Washers

MOQ10000 Piece/Pieces

MaterialStainless Steel

ShapeRound

Section ShapeRound

Thickness2.2 Millimeter (mm)

ColorSilver

WarrantyNo

Washer - Stainless Steel DIN 125, M2 to M36 Sizes, Bright Finish Without Burrs, Spring Washer Options

MaterialStainless steel

SizesM2 to M36

GradesSS 304, SS 316, SS 310, SS 321

FinishPolished

TypesPlain, Punched, Spring

StandardsDIN 125

Stainless Bolt Industries Pvt. Ltd

Ahmedabad

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller5 Years

Washers . - Color: Silver

Price: 0.5 INR/Piece

MOQ1000 , Piece/Pieces

Height127 - 177.8 Millimeter (mm)

Size5-7 Inch

ColorSilver

UsageFor Feeting

Weight10-15 Grams (g)

MaterialStainless Steel

Pipette Washer - Advanced Ultrasonic Cleaning System | Digital Temp Control, Pre-Cleaning Jet Spray, Stepless Power Control, Forced Hot Air Drying

MaterialStainless Steel

DimensionsVariable

PowerVariable

TemperatureVariable

Chambers4

ControlDigital

Samarth Electronics

Ambernath

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller4 Years

Spectrophotometer Cell Washer

MOQ3 Piece/Pieces

Display TypeNot Available

Temperature ResistanceUp to 120AdegC

Glass TypeBorosilicate Glass

Control TypeManual Plunger Mechanism

Speed RangeManual Pump Action

AccuracyPrecise Cell Washing

National Analytical Corporation

Mumbai

Trusted Seller

Trusted Seller Super Seller

Super Seller13 Years

Slotted Hex Washer

MaterialSteel

DimensionsVaried

FinishZinc-plated

Slot typeKeyed

ThicknessVariable

Head styleHex

Aira Trex Solutions India Private Limited

Bengaluru

Trusted Seller

Trusted Seller Super Seller

Super Seller4 Years

Round Stainless Steel Nut Bolt & Washer

Price Trend: 10.00 - 50.00 INR/Piece

MOQ100 Piece/Pieces

ColorSilver

Product TypeWasher

MaterialStainless Steel

SurfacePolished

ShapeRound

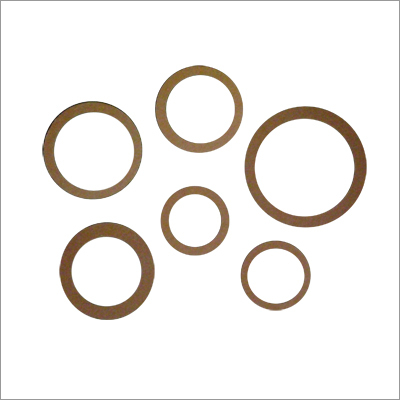

Heater Fiber Washers - Application: For Industrial Use

MOQ100 Piece/Pieces

FeatureHeat resistance, Easy to install

ShapeRound

Surface FinishMatt finish

Product TypeHeater Fiber Washers

ApplicationFor Industrial Use

ColorGolden

Industrial Screw With Captive Washers

materialSteel

head_typeHex

washer_typeCaptive

thread_typeMachine

finishZinc plated

drive_typeExternal

UHMWPE Washers

MaterialUHMWPE

SizesVarying

Wall ThicknessVarying

Corrosion ResistanceHigh

Abrasion ResistanceExcellent

Chemical InertnessYes

Electro Polymers Industries

Ahmedabad

Trusted Seller

Trusted Seller Super Seller

Super Seller3 Years

Metal Washer Fasteners

Price Trend: 650.00 - 2500.00 INR/Unit

MOQ20000 Piece/Pieces

FinishBright, Matte, Black Oxide, Polished

Load CapacityUp to 50 kN

ShapeRound

Surface TreatmentOther, Zinc Plated, Galvanized, Polished, Plain

Head TypeFlat/Plain

CapacityStandard Load Bearing

Top Rated Products

Washer - Stainless Steel DIN 125, M2 to M36 Sizes, Bright Finish Without Burrs, Spring Washer Options

Stainless Bolt Industries Pvt. Ltd

FAQs Related to Can Washer

Who are the top can washer manufacturers in India?

- Spring India

- Anil Engineering Works

- Deepak Products

- Zenith Industries

- Steelking Industries Private Limited

- Arihant Trading Co.

- Buvico Spraying Equipments

- Bhargav Brass Industries

- Ketan Engineering Co

- National Analytical Corporation

Which cities have the largest number of can washer suppliers?

- Mumbai

- Delhi

- Chennai

- Kolkata

- Pune

- Bengaluru

- Hyderabad

- Jaipur

- Ludhiana

- Ahmedabad

- Vadodara

- Faridabad

- Rajkot

- Jamnagar

- Howrah

- Thane

- Indore

- Gurugram

- Surendranagar

- Coimbatore

What kinds of brands are available for can washer?

- Skil Pressure Washer

- Bosch Car Washer

- Karcher Pressure Washer

What is the price range for can washer offered by listed companies?

| Company Name | Currency | Product Name | Price |

|---|---|---|---|

| TECHNO MAC SYSTEMS | INR | Can Washer | 48000 |

| Vinayak Dairy & Food Process Machinery | INR | Can Washer | 65000 |

| SHRI LAXMI FASTNERS | INR | MS Alloy Washer | 50 |

| Sahyog Industries | INR | MS Washer | 50 |

| RAJVIR ENTERPRISES | INR | Contact Washer | 65000 |

| SPRING INDIA | INR | Retainer Push On Fix Washers | 5 |

| KETAN ENGINEERING CO | INR | Washers . | 0.5 |

How many trusted sellers are available for can washer?

- SPRING INDIA

- JAYANT IMPEX

- STAINLESS BOLT INDUSTRIES PVT. LTD

- KETAN ENGINEERING CO

- Samarth Electronics

- NATIONAL ANALYTICAL CORPORATION

- AIRA TREX SOLUTIONS INDIA PRIVATE LIMITED

- ARIHANT TRADING CO.

- SWARNA FASTENERS

- ELECTRO POLYMERS INDUSTRIES

- DEEPAK PRODUCTS

- BHARGAV BRASS INDUSTRIES

- DIP ENTERPRISE

- BUVICO SPRAYING EQUIPMENTS

- MEET CHEM

- ZENITH INDUSTRIES

- MOTIF GRAPHICS PVT. LTD.

- NUMAX STEELS

- R.S APPLIANCES

- SHREE FIRE SERVICES

- STEELKING INDUSTRIES PRIVATE LIMITED

- MINERVA RUBBER & ENGINEERING WORKS

- PERFECT METAL WORKS

- Shree Radha Govind Electricals

What is the minimum order quantity for can washer?

Do listed companies have registration & certifications?

- NATIONAL ANALYTICAL CORPORATION

- DEEPAK PRODUCTS

- BHARGAV BRASS INDUSTRIES

- INTERNATIONAL INDUSTRIAL SPRINGS

- ZENITH INDUSTRIES

- SS ENGINEERS AND CONSULTANTS PRIVATE LIMITED

- NUMAX STEELS

- R.S APPLIANCES

- RAHUL FASTENERS & FITTINGS

- MINERVA RUBBER & ENGINEERING WORKS

- PERFECT METAL WORKS

What is the get latest price feature?

What types of payment methods are accepted by the can washer suppliers?

Bronze Casted Trust Washers - 5 Millimeter Thickness | Polished Finish, Weight Range 1 to 1000 Grams, Industrial Use

Price: 100 INR/Piece

MOQ10000 Piece/Pieces

ApplicationFor Industrial Use

Thickness5 Millimeter (mm)

Surface TreatmentPolishing

Weight (kg)1-1000 Grams

WarrantyNo

Bhargav Brass Industries

Jamnagar

Trusted Seller

Trusted Seller Premium Seller

Premium Seller14 Years

Easy To Operate And Portable Type High Pressure Jet Washer

Price: 51000.00 INR/Piece

MOQ1 Piece/Pieces

ColorGrey and Black

UsageCommercial and Industrial Use

ConditionNew

LockRite Washers - ROHS Compliant, Mechanical Zinc Plated | Vibration Proof Locking Devices with Custom Sizes Available

MaterialSteel

PlatingZinc

Testing100% Tested

SizesCustom Sizes

OriginMade In India

TypeLocking

High Pressure Jet Washers

Max Pressure180 bars

RPM2900

Motor TypeElectric

WheelsPneumatic

MaterialSteel

WeightRange

Buvico Spraying Equipments

Chennai

Trusted Seller

Trusted Seller Premium Seller

Premium Seller15 Years

Liquid Dish Washer

MaterialLiquid

Volume500ml

PackagingBottle

ScentLime

PHNeutral

BiodegradabilityHigh

Brass Press Washers Application: For Industrial Use

Price Trend: 50.00 - 200.00 INR/Piece

MOQ1000 Piece/Pieces

MaterialBrass

ShapeRound

Thickness4 Millimeter (mm)

Surface TreatmentNickel Plated

ApplicationFor Industrial Use

Cylinder Half Washer

Product TypeCan Washer

MaterialStainless Steel

ConstructionSs 304

Washing SequenceHot Water

Cleaning Capacity800 Halfs/Hour

Cylinder Capacity400 Cylinders/Hour

View More

Milk Can Washer - Capacity: 400Cph To 2000Cph Kg/Hr

Price : 900000.00 INR

Milk Can Washer Machine

Get Best Deal

High Pressure Cleaner Cone Can Washer

Price Trend : 500000.00 - 800000.00 INR

LED Wall Washers - Lightweight Aluminium Extruded Profiles | Stackable, Powder Coated, Foldable Flat Frames

Product typeLed Wall Washers

ColorBlack

MaterialAluminum

ApplicationIndoor/Outdoor

Light colorBlue

Input voltage12V

Motif Graphics Pvt. Ltd.

Mumbai

Trusted Seller

Trusted Seller Premium Seller

Premium Seller3 Years

Washers - Made from Optimum Quality Raw Material | Superior Sturdiness, Perfect Finish, Long Lasting Performance, Precise Dimensions

MaterialRaw Material

FinishPerfect

DimensionPrecise

ConstructionSturdy

PerformanceLong Lasting

QualityOptimum

Stainless Steel Hood Type Dish Washer

MaterialStainless Steel

Power SourceElectric

UseHotel, Home

Fire Extinguisher Washers - Stainless Steel, Inner Dia 10-30 mm, Black | Industrial Use, 1 Year Warranty, Precise Dimensions, Durable Finish

Price: 50 INR/Piece

MOQ100 Piece/Pieces

Product TypeFire Extinguisher Washers

ColorBlack

MaterialMetal

AlarmNo

UsageIndustrial

Warranty1 Year

Shree Fire Services

Mumbai

Trusted Seller

Trusted Seller Premium Seller

Premium Seller13 Years

Dish Washer - High Grade Stainless Steel Scrub Buds | Customizable Design, Durable and Efficient Cleaning

MaterialStainless steel

Diameter7 cm

Thickness1 cm

Quantity30

PackagingCardboard

Weight100 g

Steelking Industries Private Limited

Rajkot

Trusted Seller

Trusted Seller Premium Seller

Premium Seller17 Years

Special Washers - Corrosion Resistant, Circular Shape | Superior Finishing, Excellent Impact Strength, Easy To Fit

Price Trend: 1.00 - 5.00 INR/Piece

MOQ5000 Piece/Pieces

Payment TermsOthers, Cheque

Supply Ability100000 Per Week

Delivery Time1 Week

EPDM Washers - 2mm-50mm Size Range, Black Color, Shore A 50-70 Hardness | Ideal for Sealing & Vibration Isolation in Plumbing, HVAC, and Automotive Applications

MaterialEPDM rubber

ColorBlack

HardnessShore A 50-70

Temperature Range-40°C to 120°C

Size Range2mm-50mm

UsageSealing, vibration isolation in various applications like plumbing,HVAC,computers, and automotive

Minerva Rubber & Engineering Works

Mumbai

Trusted Seller

Trusted Seller Premium Seller

Premium Seller10 Years

Fiber Washers - Fiber Material, Standard Sizes and Shapes | Durable and Versatile for Industry Demands

MaterialFiber

ColorRed

ShapeRound

ThicknessVariable

Inner diameterVariable

Outer diameterVariable

Perfect Metal Works

Mumbai

Trusted Seller

Trusted Seller Premium Seller

Premium Seller4 Years

Brass Nuts Bolts and Washers - Premium Quality Brass, Various Sizes Available | Superior Finish, Durable Performance

MaterialBrass

Size RangeM3-M12

Thread TypeMetric

FinishNatural

UsageFastening applications in various industries; marine, plumbing etc.

StandardsIS/DIN

Shree Radha Govind Electricals

Jaipur

Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

Latest from Can Washer

Can Washer

By:

Dk Foods

Cone Can Washer

By:

Ss Engineers & Consultants

Crate Washer

By:

Siddhi Vinayak Enterprises

Food Canning Machinery

By:

Essgee Exports India

Customized Stainless Steel Reactor

By:

Zibo Tanglian Chemical Equipment

Stainless Steel Can Washer

By:

Pray Dairy Machinery Industries

What is can washer and it’s uses?

The internal and external surfaces of the cans are cleaned and prepared by the can washer.

Can washers are used in the many stages of the beverage and food can industry. Can washers have a maximum cleaning capacity of 6,000 cans per minute. Use our innovative Belt Vacuum System to recover and recycle valuable chemical resources.

The Can Washer has removable roof panels that allow access to the full length of the washer inside, reducing the time and cost of maintenance.

For ease of maintenance and operator safety, our spray risers have full-length guide rails and innovative quarter-turn quick couplings.

When using a bolted joint such as a bolt and nut, a washer is a mechanical component typically used to prevent the bolt from loosening or to spread the weight of the nut or bolt head over a larger area. Soft steel narrow flat rings are often used for load distribution.

Types of can washer

Can scrubber

These can washers are very simple in design and operation. A cylindrical hard nylon fibre brush "A" rotates around its axis as shown in the illustration and is driven by a small electric motor of typically 0.5 to 0.75 HP. The attached gear drives another brush "B". On one side of the scrubber there is a single stationary brush "C", which matches the shape of the can.

Cans are often washed in a scrubber using the following method:

-

Pour the required amount of detergent into the wash after filling.

-

The solution should be heated to 45-50Oc.

-

Turn on the motor of the can scrubber to rotate the brushes.

-

The can should be taken out of the drip saver and inserted into the scrub brush "A" from the free end side.

-

Hold the can long enough for the contents to fall out.

-

While the rotating brush "B" and a stationary side brush with a unique design scrape the outside of the can, brush "A" cleans the inside of the can.

-

Remove the cans and rinse them in cold water.

-

Check the cleaning progress with clean hands.

Can Steaming Block

After manually cleaning the cans, the sterilisation is carried out either by steam sanitization through steaming blocks or by spraying a cold sanitizer solution.

Design and Function

This apparatus is specifically made to hold cans upside down. The cleaned can is sterilised by being injected with live steam until it gets hot using paddle-operated steam and water jets.

The main safety measures required when using a steam block are to ensure that the flush/steam injection valve is working and that steam is being injected. To prevent burns, the operator's safety must be ensured when handling the hot can. Cans are sometimes held by the operator for short periods of time, which can lead to inefficient operations. The can should be in the correct position before the rinse or steam valve is opened to prevent accidents from hot water splashes. A steam pressure of 2 to 3 kg/sq cm is sufficient to achieve the desired result.

Maintenance

-

Check and clean the nozzle holes regularly.

-

Check and adjust the spring tension of the paddle valve.

-

Maintain cleanliness and clean drain holes.

Rotary Can Washer

These can washers are automatic or semi-automatic and effectively rinse, clean and sterilise cans. The machine features are listed below.

Construction

This type of washer is made of very simple materials and carries the cans on a large rotating table or carrier (Fig.). Cans with irregular shapes can be cleaned without any safety concerns. These are relatively small machines, available in various sizes to handle small to medium numbers of cans.

Check the effectiveness of the cleaning as a precaution. Dented or heavily soiled cans should be scrubbed in a can scrubber before loading into a rotary can washer.

Maintenance

-

Pumps and jets, like other can washers, require frequent maintenance.

-

Lubricate moving parts daily or as recommended by the manufacturer.

-

Inspect and maintain the stuffing box, oil seal and water seal.

-

Close all doors except the entrance and exit.

Straight-through can washer

The washer contains compartments for rinsing, detergent spraying, hot water rinsing, steaming and air drying.. The cans are carried to the exit door by steel or plastic chains specially designed to grip and carry the can. In other types of moving systems, the cans are moved from one position to the next by a ratchet. From the entry door, the can moves upside-down to the rinsing area, where loose soil and some dirt are washed off by warm water injected from below and from the other sides. These cans are then moved to the rinsing section where a hot rinsing solution at a concentration of 0.5 to 1% is sprayed over the inside and outside of the cans to completely remove the soil.

The hot water rinse stage removes detergent and soil residues from these cans. The cans are now thoroughly cleaned and transferred to the steam area for sterilisation. Finally, the hot cans are dried in the air drying area. By using a suitable attachment, the overturned cans are returned to their upright position with their mouths open before reaching the exit door.

How does a can washer work?

It uses centrifugal force to move the particles to the bottom of the tube. In the above processes, both processes use centrifugal force and work in the same way. So we can say that the working principle of the washing machine is centrifugation.

Maintenance and care for can washer

-

Water hoses should be replaced. Inspect hoses regularly for signs of bulging, cracking, fraying and leaks near the ends. As part of a preventive maintenance programme, replace the hose every three to five years or whenever a problem is detected.

-

Adjust the unit. To prevent the hose from kinking, make sure there is at least four inches between your washing machine and the wall.

-

Keep the appliance level. A washing machine that is not level can cause damage to the machine or floor during the spin cycle by rocking, vibrating or moving across the surface.

-

Turning the feet anti-clockwise to raise the washing machine and clockwise to lower it helps to maintain balance.

FAQs: Can Washer

Q. What are the different types of can washer available

Ans. A can washer uses 14 gallons of water per load, while a standard washing machine uses 20 gallons of water per load.

Q. Can a can washer be used to sanitize containers?

Ans.

-

Rinse the outside of the canister to remove dirt and debris.

-

Use detergent and water to clean the outside of the hopper.

-

Use a high pressure spray hose for harvesting containers.

-

Use clean, potable water for rinsing.

Q. What are the typical cleaning cycle time for a can washer?

Ans. An average wash cycle typically takes between 50 and one hour to complete. However, depending on the size of the load and the cycles or settings you choose, this time may be shorter or longer.

Q. Does a can washer require a lot of water to operate?

Ans. A standard can washer can use up to 45 gallons of water per load.

Can Washer Price List

Product Name | Expected Price |

|---|---|

| Can Washer | 48000 |

| Can Washer | 65000 |

| MS Alloy Washer | 50 |

| MS Washer | 50 |

| Contact Washer | 65000 |

| Retainer Push On Fix Washers | 5 |

| Washers . | 0.5 |

This Data was Last Updated on 2025-11-11

Can Washer Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Spring India Mumbai, India | 25 Years |

Anil Engineering Works Sonipat, India | 17 Years |

Deepak Products Jamnagar, India | 17 Years |

Zenith Industries Jamnagar, India | 17 Years |

Steelking Industries Private Limited Rajkot, India | 17 Years |

Arihant Trading Co. Mumbai, India | 16 Years |

Buvico Spraying Equipments Chennai, India | 15 Years |

Bhargav Brass Industries Jamnagar, India | 14 Years |

Ketan Engineering Co Mumbai, India | 13 Years |

National Analytical Corporation Mumbai, India | 13 Years |

Upcoming Tradeshows

Fire, Safety & Security Expo 2026 (PFSS)

Thu, 07 May, 2026 - Sat, 09 May, 2026

India Food Pack Expo 2026

Tue, 20 Jan, 2026 - Thu, 22 Jan, 2026

Asia Labex 2025

Thu, 13 Nov, 2025 - Sat, 15 Nov, 2025

Vyapaar Expo 2026

Fri, 30 Jan, 2026 - Sun, 01 Feb, 2026

The Harit Bharat Expo 2026

Fri, 16 Jan, 2026 - Sun, 18 Jan, 2026

Power On 2026

Fri, 23 Jan, 2026 - Sun, 25 Jan, 2026

SVUM 2026 INTERNATIONAL TRADE SHOW

Wed, 11 Feb, 2026 - Fri, 13 Feb, 2026

Automechanika Dubai 2025

Tue, 09 Dec, 2025 - Thu, 11 Dec, 2025

CIFF - China International Furniture Fair Guangzhou 2026

Wed, 18 Mar, 2026 - Sat, 21 Mar, 2026

ET TECH X 2025

Thu, 11 Dec, 2025 - Sat, 13 Dec, 2025

Popular Categories