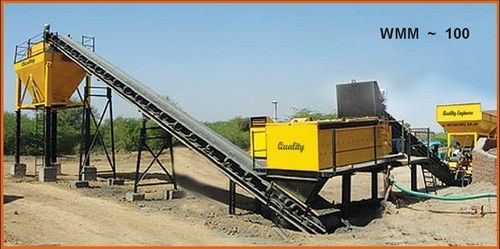

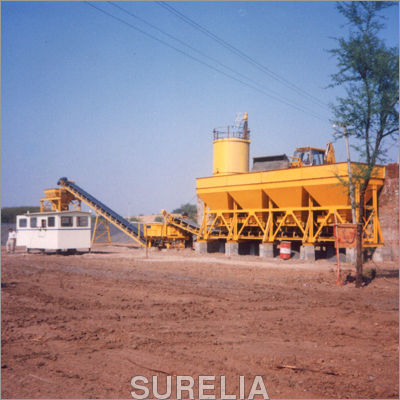

Wet Mix Macadam

Price:

Get Latest Price

In Stock

Product Specifications

| Unit Output | 100/180 Tph |

| Feeder Capacity | 48/76 Mt |

| Bin Feeding Width | 2.9 M |

| Pug Mill Capacity | 1.5/2 Cu.M |

| Connected Load | 75.5/92.5 Hp |

| Storage Silo | 12/25 Ton |

| Generator Capacity | 80/125 Kva |

| Features | Fast Mixing, Homogenous Mix, Adjustable Gates, Durable Design, Easy Operation, High Output, Precise Control, Corrosion Resistant |

Product Overview

Key Features

Wet Mix Macadam

We are involved in providing a wide range of Wet-Mix Macadam Plants to the patrons. These products are manufactured using high-grade components and accessories at our production unit. Available in fixed or variable speed drives, the plant has adjustable gates at its bins. Owing to the design of twin shaft pug mill, aggregates & additives can be mixed quickly, continuously and homogeneously. Further, these wet mix Macadam plants are subject to stringent checking to ensure their dimensional accuracy, resistance to corrosion and compliance with set industrial benchmarks.

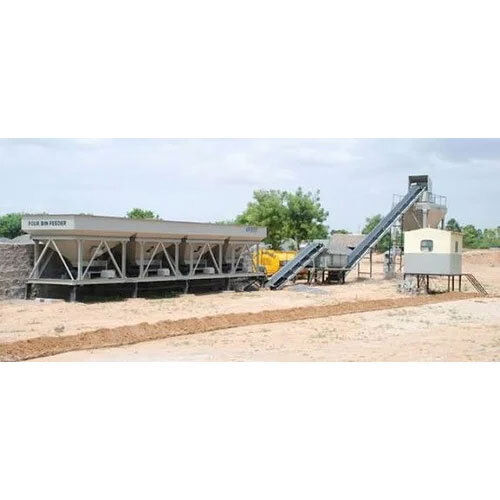

Four Bin System

4 Bin aggregate. Feeder unit with storage bin 7.5 M3 each for 100 TPH & 12 M3 each for 180 TPH. Feeder bins are provided with auxiliary belt conveyor. Sand Bin is provided with vibrator.

Steep bin walls and valley angles allow free flow of aggregates from the feeders minimizing hand up of materials in the corners and brinding with sticky aggregates. The bins are equipped with adjustable gates. The optional variable speed drive with proportional controls, offers greater flexibility and accuracy of operation.

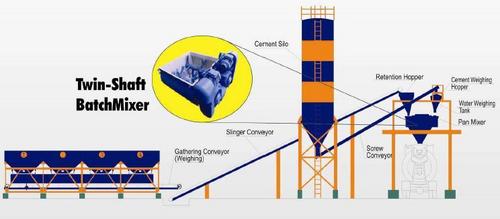

Pug Mill Unit

The Twin shaft pug mill design provides fast, continuous and homkogenous mixing of aggregates. The shafts are mounted on extra heavy resistant alloy steel selection for paddle arm and tips ensures a long life. The liner plates are corrosion and abrasion resistant.

Water Arrangement

Self-priming pump and spray bar with water flow meter for accurate metering Control from the main operating panel.

Controls and Automation

The weather protected cabin houses the user-friendly controls that are specifically designed fo rconstruction site condition. The control panel ensures sequential operation of the various deives nad precise control. An emergency stop in the form of a push button located close to the pug mill unit affords additonal safety.

Storage Silo

The storage silos 12 Ton in 100 TPH (Option as required) & 25 Ton in 180TPH is rigid, easy to erect. Anti Segregation hopper at discharge point minimizes mix segregation. Fast opening hydraulically operated gates facilitate quick discharge of mix material into the truck without segregation.

Technical Specifications

| Uunit | Output | WMM - 100 | WMM - 180 |

| 100 TPH | 180 TPH | ||

| Four Bin Feeder | Capacity | 12 x 4 = 48 MT | 19 x 4 = 76 MT |

| Bin Feeding Width | 2.9 M | 2.9 M | |

| Auxiliary Belt Conveyor | W 500 mm / 2 HP | W 500 mm / 2 HP | |

| Gathering Belt Conveyor | W 600 mm / 10 HP | W 750 mm / 10 HP | |

| Bin Vibrator | 1 HP | 1 HP | |

| Conntected Load | 19 HP | 21.5 HP | |

| Vibrating Screen | Screening Area | 1.4 M2 | 1.4 M2 |

| Sonnected Load | 3 HP | 3 HP | |

| Charging Conveyor | W 600 mm / 7.5 HP | W 750 mm / 10 HP | |

| Pug Mill | Aggregate Capacity | 1.5 Cu. m | 2 Cu. m |

| No. of Arms | 11 x 2 = 22 | 15 x 2 = 30 | |

| Connected Load | 30 HP | 40 HP | |

| Water Pump | Connected Load | 3 HP | 3 HP |

| Hydraulic Power Pack | Connected Load | 3 HP | 5 HP |

| Storage Silo | 12 TON | 25 TON | |

| Load out Conveyor | W 600 mm / 10 HP | W 750 mm / 12.5 HP | |

| Total Connected Load | 75.5 HP | 92.5 HP | |

| Generator set | Recommended Capacity | 80 KVA | 125 KVA |

Company Details

Business Type

Exporter, Manufacturer, Service Provider, Supplier

Employee Count

100

Establishment

1985

Working Days

Monday To Sunday

GST NO

24ADCFS8129H1Z0

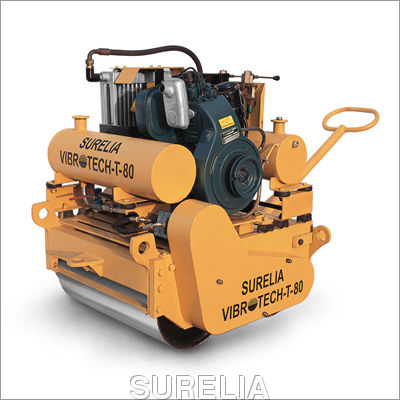

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 24ADCFS8129H1Z0

Ahmedabad, Gujarat

Managing Partner

Mr. Shailesh Surelia

Address

PLOT NO. 79/A, PHASE - 1, OPP WATER TANK, G.I.D.C., VATVA, Ahmedabad, Gujarat, 382445, India

wet mix macadam plant in Ahmedabad

Report incorrect details