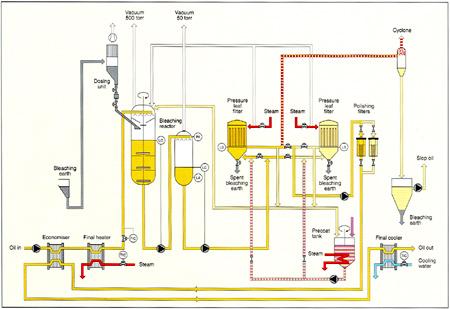

Wet Bleaching Process

Price:

Get Latest Price

In Stock

Product Specifications

| Reactor Type | Vertical |

| Reactor Material | Stainless Steel |

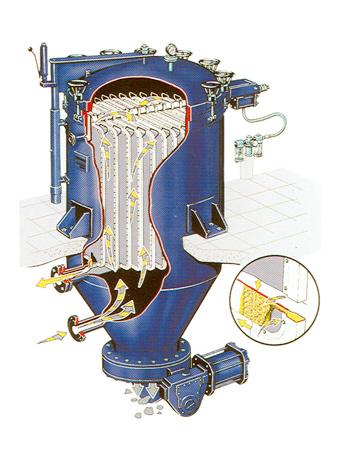

| Filter Type | Pressure Leaf |

| Vacuum Level | Medium |

| Water Content | 0.5% |

| Steam Pressure | Variable |

| Cyclone Type | Horizontal |

| Features | Efficient Bleaching, Cost Effective, Reduced Earth Use, Improved Filtration, Oil Recycling, Soap Removal, Lower Oil Loss |

Product Overview

Key Features

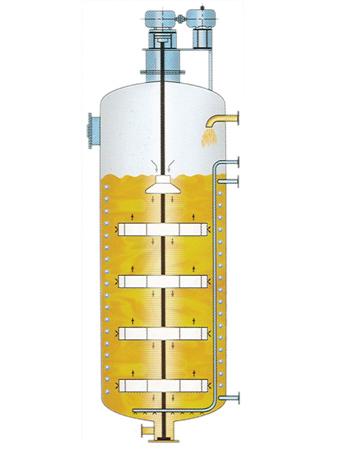

As wet bleaching implies, the oil in contact with the bleaching agent contains some water during the reaction time. The amount is maxium 0.5%, but even this amount of water would create filteration problem if it is left in the mixture. For this reason a wet bleaching plant has an extra drying vessel between the bleaching reactor operates at a medium vaccum level.

To maintain the correct water content, the bleaching reactor operates at a vaccum level.

So why we use wet bleaching ? The simple answer is economics. If wet bleaching utilises the earth more sfficiently, then you use less earth, and consequently will have lower earth costs, and lower losses of oil retained in the spent earth.

One way of obtaining the right amount of water in the oil is to by-pass the drying stage in euther a neutralising, or demugging plant, and feed directly to the bleaching reactor.

Another technique is to intensively mix a small amount of a dilute acid solution into the feed to bleaching. This not only sets the water content, but it also removes soaps which can lead to a further reduction in the amount of bleaching agent needed.

The filters are arranged so that the oil can be recycled. Either through the reactor, or a via a pre-coat tank, or fed to the other filter when cleaning is required. Oil in the filter cake is reduced by steam blowing. The oil in the steam is separated in a cyclone and returned to a slop oil tank.

Company Details

Focusing on a customer-centric approach, RITIKA CONSULTANTS has a pan-India presence and caters to a huge consumer base throughout the country. Get Plant & Machinery from RITIKA CONSULTANTS at Trade India quality-assured services.

Business Type

Exporter, Manufacturer, Service Provider, Supplier

Employee Count

5

Establishment

2004

Related Products

Explore Related Categories

More Product From This seller

Seller Details

New Delhi, Delhi

Accepts only Foreign inquiries

Ceo

Mr. Nalini Ranjan

Address

Building No. 2nd Floor, B-365, C R Park, New Delhi, Delhi, 110019, India

Report incorrect details