Vibratory Stress Relief For Weld Repaired Jobs

Price:

Get Latest Price

In Stock

Product Specifications

| Capacity | 150 tons |

| Process Time | 1 hour |

| Materials | Various metals |

| Power | 230V |

| Dimensions | Variable |

| Weight | Heavy |

| Usage | Weld repair stress relief |

| Features | Fast process, Cost effective, Environmentally friendly, Portable unit, Wide application |

Product Overview

Key Features

Advantages of Vibratory Stress Relief Equipment

- The process is more technically sound

- The working cost works out to less than 35% than that of thermal stress relieving,

- Ease of operation - as and when required and as many times as required,

- The process is very fast ( a job of 10 tons would require just about 1 hour)

- Environmentally friendly (no chemicals used, gases formed or heat produced)

- Portable - machine can be easily taken to the job (no hassles of transporting the job to the furnace site or unnecessary material handling)

- The process is very clean (no scale cleaning operation which may be required after thermal stress relieving).

- A single job 500 kgs up to 150 tons (irrespective of shape, size, volume, material) can be stress relieved by this machine.

- Can be used on a wide variety of ferrous and non ferrous materials - non heat treatable dissimilar materials; non heat treatable alloys; ground & fine finished material - including Cast steel, Cast iron, Carbon steels, Stainless steel, Aluminum, Manganese.

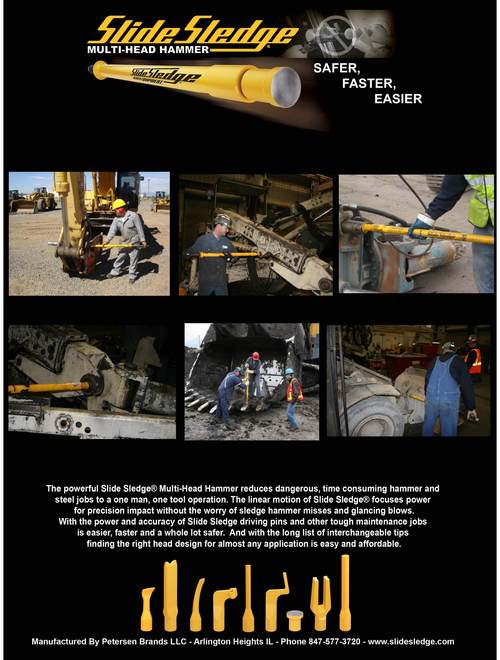

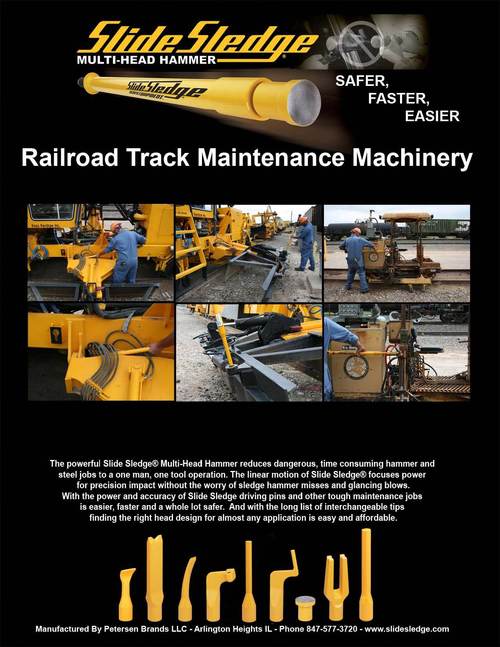

- Can be used on wide variety of applications - Castings, Fabrications, Machined components, Shafts, Gears, Weld repaired jobs and stresses caused by machining, milling, grinding, punching, broaching, stamping, boring, planning, cutting, forging.

- Can be used during welding process - during & after welding; in between machining steps.

- There is no detrimental effect on the work piece materials (s) - will not change the metallurgy or structurally or chemically; will not change the hardness; produces a surface clean & free from discoloration, slag or scale.

For the effective vibratory stress relief of

- Heavy fabrications

- Fabricated structures

- During welding to control distortions

- Weld repaired jobs

- Castings

- Machined components

- Aluminium

- Stainless steel

Company Details

Business Type

Importer, Service Provider, Distributor, Supplier

Employee Count

6

Establishment

2002

Working Days

Monday To Saturday

GST NO

27AABCG8622J1ZG

More Product From This seller

Seller Details

GST - 27AABCG8622J1ZG

Bhosari, Maharashtra

Accepts only Domestic inquiries

Managing Director

Mr K.m.p.s. Nagpal

Address

87, General Block, M.I.D.C. Bhosari, Maharashtra, 411026, India

Report incorrect details