Tablet Press With Isolation (Containment Solution)

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Stainless Steel |

| Dimensions | Customizable |

| Pressure | Negative |

| Filtration | Hepa |

| Gloves | Hypalon |

| Control | Pneumatic |

| Motor | Centrifugal |

| Features | Modular Design, Total Isolation, Ergonomic Design, Gasket Sealed, Safe-Change Hepa, Negative Pressure, Easy Cleaning, Leak-Proof Lock |

Product Overview

Key Features

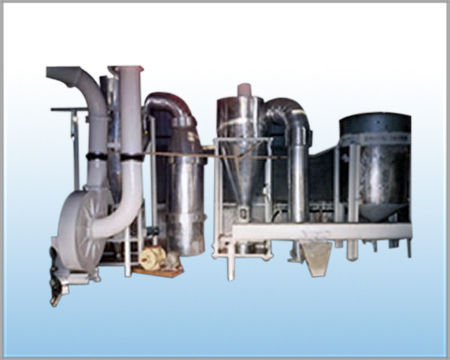

Our isolator is designed to provide a locally controlled environment operating at a negative pressure, with the ability to control and monitor all operating parameters , our systems can be designed to handle tableting process.

Outstanding Features: (Tablet Press with Containment Solution)

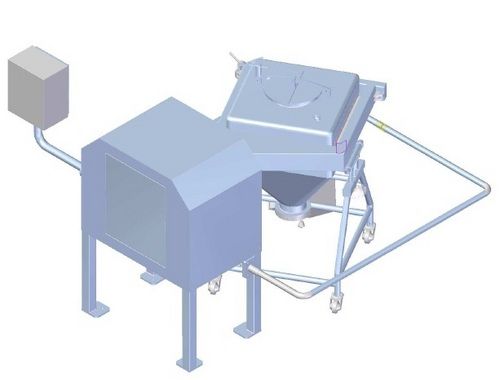

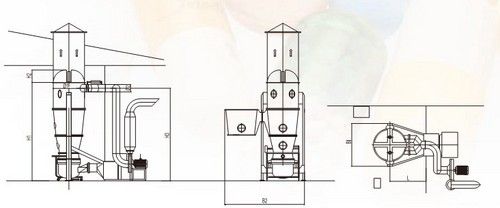

Modular machine design allows for a total isolation of the Tablet Compression Process.

Gasket sealed front sash main doors.

Chambers doors are sealed and inter-locked during operation.

Round glove port and Hypalon gloves for access to the various chambers

Toughened glass front sash for various chambers with glove port arrangement and electromagnetic lock.

Provision of Integration with de-dusting and metal detector equipment with power supply sockets

Integrated centrifugal motor blower with limited duct work

Spray gun with proper silicone hose connections for manual cleaning

Dedicated pneumatic control panel for Inflatable gasket for main chamber lock ensuring leak-proof door lock while process is in operation

Differential Pressure across chamber with respect to ambient is Negative

Ergonomically designed for ease of use

Safe-change HEPA filtration

Company Details

Over 30 years experience in Solid Dosage machinery Possessing a sound in-depth knowledge and understanding of the pharma machine manufacturing, we have kept pace with the needs of the fast growing pharma industry today. What makes us unique is our ability to solve the technical queries by our core team to pursue customers delight. Over the years we have attributed our learning curve and growth to their valuable suggestions. Taking this faith and going one step forward in our journey, we hope to attain a healthy pan-India presence followed by the global footprints. Vision At Chamunda, we believe that every day is a constant endeavor to nurture our passion and ignite the dynamic spirit in the attainment of excellence. Mission Envisaging a bright future in the pharma sector and taking reliability as our benchmark, Chamunda hopes to build on its reputation as a force to reckon within offering total tableting solutions to both Indian and global markets. We have our eye firmly on delivering quality engineering and servicing with cost effective tableting solutions. Our focus remains committed to synergizing of our expertise with next-gen Industry standards.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

250

Establishment

1981

Working Days

Monday To Saturday

GST NO

24AABCC1690E1Z3

Payment Mode

Cheque/DD, Cash, Wallet & UPI

Related Products

More Product From This seller

Seller Details

GST - 24AABCC1690E1Z3

Ahmedabad, Gujarat

Executive Director

Mr. Prasen Suthar

Members since

1 Years

Address

Plot No. 7602, Near Ramol Cross Roads, G.I.D.C Vatva, Ahmedabad, Gujarat, 382445, India

Machineries in Ahmedabad

Report incorrect details