Sparkler Filter By S. F. Engineering Works

Price:

Get Latest Price

In Stock

Product Specifications

| Features | High Flow Rate, Easy Operation, Versatile Media, Complete Recovery, Uniform Clarity, Economical Use, Cake Stability, Leak Proof Design |

Product Overview

Key Features

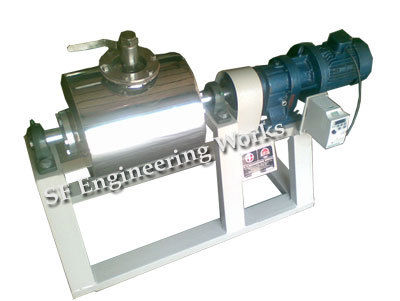

SPARKLER FILTERS STANDARD HORIZONTAL PLATE FILTER

The Sparkler Horizontal Plate Filter is designed for polishing and for security filtration of liquids with limited solid contents. Design features include: Maximum cake stability due to horizontal position of filter plates, Ability for intermittent operation, complete recovery of product by the scavenger plate, No unfiltered hold-over, and Perfect sealing of filter media by tie rod compression at center and periphery of all filter plates.

The Standard Horizontal Plate Filter is compatible with any kind of filter media (fabric, metallic wire cloth, or filter paper) and all types of filter aids. Due to the position of the plates, only a very thin precoat of filter aid is necessary. The cake is evenly distributed, assuring economical operation and uniform clarity. All Horizontal Filter Plate Vessels can be supplied with a heating or cooling jacket.

Filter Cartridge Sizes - 8", 14 18 24", 33"

Available Filter Plate Materials Carbon steel, Most Stainless Steels, Many Exotic Metals, Polypropylene

Available Filter Housing Materials Carbon steel, Most Stainless Steels, Many Exotic Metals (Note: Housings available with a variety of linings)

Filtration Area Up to 350 sq. ft

Types of Filter Media Available Since the media is clamped in position by means of positive bolted action, all types of filter papers, woven wire, membranes, and cloth on the market may be used.

DESCRIPTION:

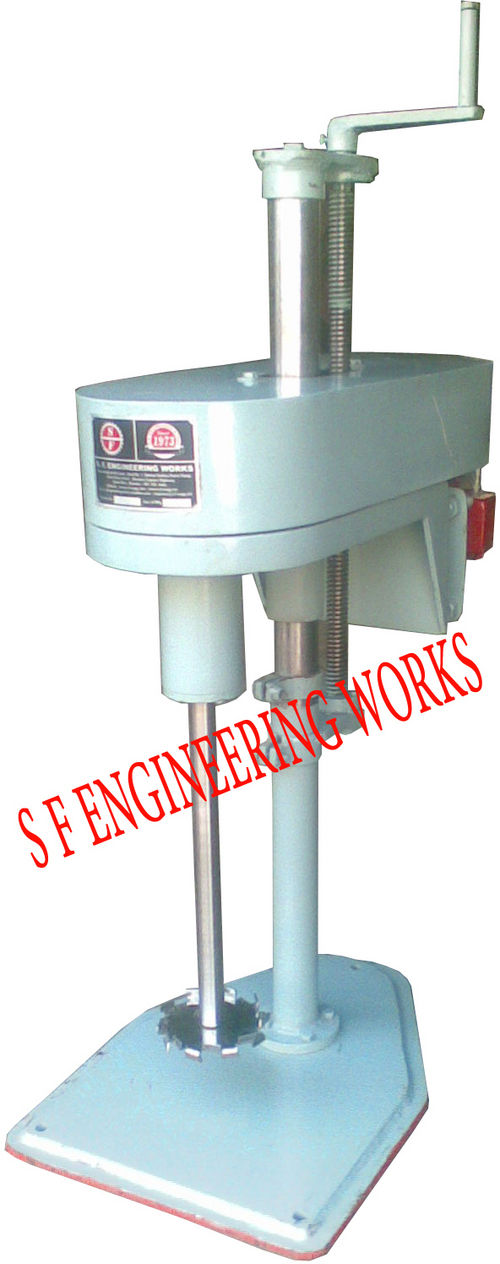

S.F. HORIZONTAL FILTER PRESS IS SPARKLER TYPE. Totally enclosed air sealed leak proof filtration plant assembly. It consists of a filter cartridge assembly having material of construction Mild steel or stainless steel 304,316,316L filter plates, support screen, having interlocking cups and fitted in the Main shell tank. Filter is equipped with special arm device in Mild steel for quick opening of filter lid cover. Unit provided with all interconnecting pipelines and Ball valves having inlet/outlet/transfer/air vent, valve pressure gauge assembly, and suitable pump with ISI make TEFC/FLAME PROOF motor, with V belt and pulley drive. The whole unit is mounted on SS or MS trolley fitted with fiber or Cast Iron castor wheel for easy movement.

OPERATION:

The liquid to be filtered is pumped to the tank, where it enters into the individual plates. It passes through the filter media (Paper/Cloth) and crystal clear filtrate comes out through a central channel formed by interlocking cups. The cake formed between the plates can be obtained if required.

SALIENT FEATURES:

Manufactured from Mild steel, Stainless steel 304/316/316L quality, argon is welded and mirror polished.

It can be provided with different types of pumps depending in the viscosity of liquid and output i.e. Gear Pump/ Centrifugal Pump/ Lobe Pump/ Roto Pump.

M.S. / S.S. Jacket is provided for hot filtration & Cooling.

Provided with bypass system & safety valve.

Sample collecting device is provided.

Complete Mild Steel or Stainless Steel stand with fiber or Cast Iron castor wheels and MS or SS cover to the motor.

Arrangement provided to remove last drop of liquid from Scavenger plate.

It is used for crystal clear filtration of pharmaceuticals, chemicals, resins, beverages, distillery, oil, ink, and other industry.

Model No | Dia Of Plate | No Of Plates | Filtration Area M2 | CAKE HOLDING CAPACITY IN LTRS | Flow Rate Ltrs/Hr | Size Of Pump | H.P of Motor | |

Maximum | Function | |||||||

SFHF 8X3 | 8 | 3 | 0.1270 | 2.920 | 2.120 | 300 | | 1 |

SFHF 8X4 | 8 | 4 | | | | | | 1 |

SFHF 8X6 | 8 | 6 | 0.2230 | 5.110 | 3.710 | 525 | 1 | 1 |

SFHF 8X8 | 8 | 8 | 0.2862 | 6.570 | 4.770 | 675 | 1 | 1 |

SFHF 8X10 | 8 | 10 | 0.3490 | 8.030 | 5.830 | 825 | 1 | 1 |

SFHF 14X4 | 14 | 4 | 0.4920 | 18.250 | 13.250 | 1000 | 1 | 2 |

SFHF 14X6 | 14 | 6 | 0.6888 | 25.550 | 18.550 | 1400 | 1 | 2 |

SFHF 14X8 | 14 | 8 | 0.8856 | 32.850 | 23.850 | 1800 | 1 | 2 |

SFHF 14X10 | 14 | 10 | 1.0825 | 40.150 | 29.150 | 2200 | 1 | 2 |

SFHF 18x4 | 18 | 4 | 0.8230 | 19.000 | 10.500 | 1700 | 11/2 | 2 |

SFHF 18X6 | 18 | 6 | | | | | | 2 |

SFHF 18X8 | 18 | 8 | 1.4814 | 34.200 | 18.900 | 3100 | 11/2 | 2 |

SFHF 18X10 | 18 | 10 | 1.8106 | 14.800 | 23.100 | 3740 | 11/2 | 2 |

SFHF 18X11 | 18 | 11 | | | | | | |

SFHF 18X15 | 18 | 15 | 2.6336 | 60.800 | 33.600 | 5440 | 11/2 | 2 |

SFHF 18X18 | 18 | 18 | | | | | | |

SFHF 18X20 | 18 | 20 | 3.4566 | 79.800 | 44.100 | 7140 | 11/2 | 3 |

SFHF 18X23 | 18 | 23 | 3.9504 | 91.200 | 50.400 | 8160 | 11/2 | 3 |

SFHF 24X11 | 24 | 11 | | | | | | 2 |

SFHF 24X15 | 24 | 15 | | | | | | 2 |

SFHF 24X18 | 24 | 18 | | | | | | 2 |

SFHF 24X21 | 24 | 21 | | | | | | 3 |

SFHF 24X24 | 24 | 24 | | | | | | 3 |

SFHF 33X7 | 33 | 7 | 4.3224 | 115.200 | 64.00 | 7920 | 2 | 3 |

SFHF 33X10 | 33 | 10 | 5.9433 | 158.400 | 88.000 | 13640 | 2 | 5 |

SFHF 33X11 | 33 | 11 | | | | | | |

SFHF 33X14 | 33 | 14 | 8.1045 | 216.000 | 120.000 | 18600 | 2 | 5 |

SFHF 33X15 | 33 | 15 | | | | | 2 | 5 |

SFHF 33X19 | 33 | 19 | | | | | | |

SFHF 33X20 | 33 | 20 | 11.3463 | 302.400 | 168.000 | 26100 | 2 | 5 |

SFHF 33X21 | 33 | 21 | | | | | | |

SFHF 33X24 | 33 | 24 | | | | | 2 | 5 |

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

15

Establishment

1973

Working Days

Monday To Sunday

GST NO

27ARUPS7370Q1ZE

Certification

ISO 9001 : 2015

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27ARUPS7370Q1ZE

Mira Bhayandar, Maharashtra

Proprietor

Mr Fayazulla Z. Sayed

Members since

21 Years

Address

SHANTA INDL. ESTATE, SHED NO-1, BEHIND DODHIA PETROL PUMP, W.E. HIGHWAY, KASHIMIRA-MIRA ROAD, Mira Bhayandar, Maharashtra, 401104, India

sparkler filters in Mira Bhayandar

Report incorrect details