Slitline 35

Price:

Get Latest Price

In Stock

Product Specifications

| Max web width | 1300 mm |

| Max unwind diameter | 1000 mm |

| Unwind core diameter | 76 mm |

| Max rewind diameter | 450 mm |

| Min slit width | 50 mm |

| Max speed | 350 m/min |

| Materials | Plastic films, laminates |

| Features | Precise tension control, Accurate web guiding, Fast slitting speed, Easy operation, Durable design, High productivity, Minimal downtime |

Product Overview

Key Features

Slitline 35

Machine Control System

Entire machine is controlled and supervised by PLC/PPC. The BUS SYSTEM for machine automation maintains tight synchronization between PLC/PPC and drives, providing fast, reliable, and error less communication. Master control panel consists touch screen operator interface located at rewind side.

Frame Structure

Carefully and methodically machined strong and sturdy heavy duty steel frame structure machined on CNC-VMC, maintains accuracy over long dependable life. Distinctively designed structure ensures less vibration even with optimum line speed. All components undergoes extensive tests, ensures optimum performance and longer equipment life.

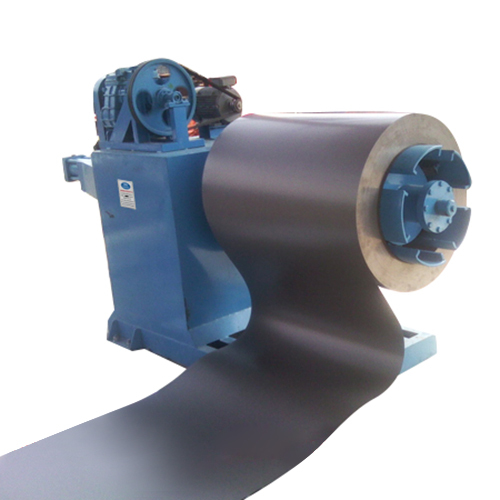

Stand-alone Unwind Tension Control

Automatic web tension control system on unwind equipped with pneumatic reel lifting system consists of latest generation AC digital drive, servo motor and pair of load-cell. The system maintains tension precisely throughout the reel run up to the core diameter.

Web Guiding System

Digital web guiding system maintains precision alignment of the web entering the draw unit. The web is guided by edge and printed (continuous or broken) lines. The system consists of camera based digital web guideing system with a linear correction of +- 5omm and PMDC motor etc.

Slit Reel Unloading

Pneumatically operated shaft supporting arms facilitate quick unloading of the slit reels from differential shafts.

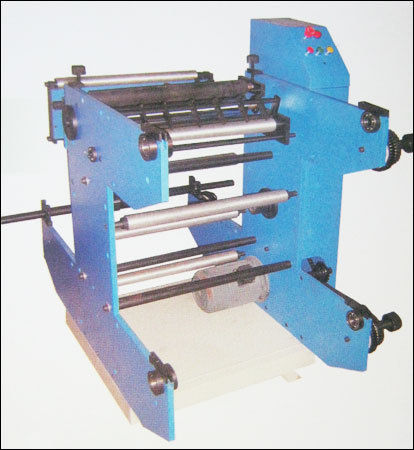

Draw Unit

By using latest generation AC digital drive and servo motor, web tension control is maintained precisely. The draw unit pulls the substrate from unwind and isolates the tension between unwind and rewind. Draw unit mainly composed of AC servo motor and drive, mat chromium plated steel roller and pneumatically loaded rubber covered nip roller.

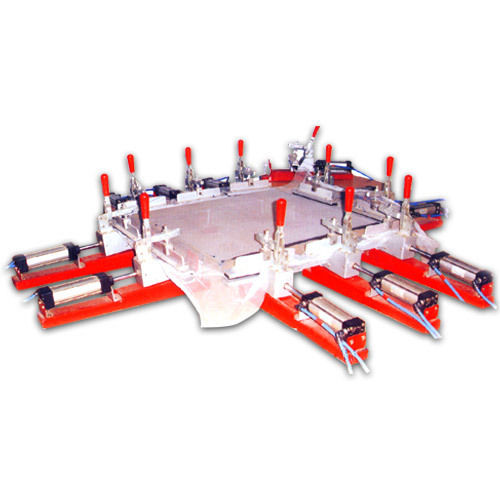

Rewind Tension Control

Hi-performance differential winding system consists of AC digital drive, servo motor, load- cells, ultrasonic sensor etc. The system allows the operator to enter the set tension, taper tension and over speed values according to the nature of substrates and the system will maintain the desired tension automatically.

Differential Winding System

Hi-performance differential winding system utilizing Ball lock units, ensures constant tension regardless of different width of the reel being rewound on the same shaft. Normal web profile variation is automatically compensated by the differential winding system. It also increases productivity and minimizes downtime.

Lay-on Rollers

Each rewinder is equipped with pneumatically operated lay-on assembly, consists of rubber rollers and backing rollers on a pair of arms.

Technical Specifications

| POSITION, TYPE OF UNWIND | SEPARATE |

| MAXIMUM WEB WIDTH | 1300 MM |

| MAXIMUM UNWIND DIAMETER | 1000 MM |

| UNWIND CORE INNER DIAMETER | 76 MM |

| MAXIMUM REWIND DIAMETER | 450 MM |

| REWIND CORE INNER DIAMETER | 76 MM |

| MINIMUM SLIT WIDTH | 50 MM |

| MAXIMUM MACHINE SPEED | 350 MM |

| MATERIALS HANDLED | PLASTIC FILMS, FLEXIBLE PACKAGING LAMINATES, PAPER AND ALUMINUM FOIL BASED LAMINATE |

Company Details

Focusing on a customer-centric approach, NAPH GRAPHICS PVT. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Printing Machinery in bulk from NAPH GRAPHICS PVT. LTD. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

50

Establishment

1996

Working Days

Monday To Sunday

GST NO

09AAACN9545Q1ZM

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 09AAACN9545Q1ZM

Noida, Uttar Pradesh

Director-technical Sales

Mr. Ashu Bharaj

Address

Unit 1, D-93, Sector-63, Noida, Uttar Pradesh, 201307, India

slitting line in Noida

Report incorrect details