S.s Tubes For Automotive Applications

Price:

Get Latest Price

In Stock

Product Specifications

| Material | 409L Stainless Steel |

| OD Range | 12.70-65.00 mm |

| Thickness Range | 1.0-2.0 mm |

| Length | Customizable |

| Manufacturing Process | TIG Welding |

| Standards | ASTM A249 |

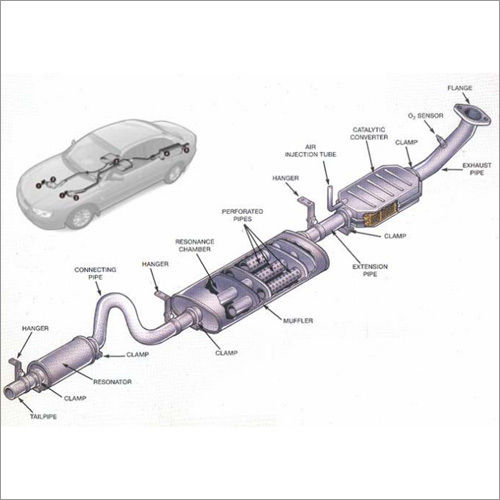

| Usage | Automotive exhaust systems, catalytic converters, mufflers |

| Features | Lightweight, Strong, Corrosion resistant, Durable, High-temperature resistant |

Product Overview

Key Features

AISI or SUS 409L 9 rade material

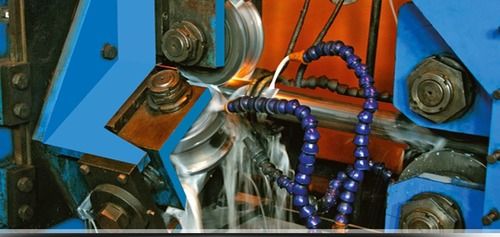

We are a prime manufacturer of S.S. Tubes of Grade 409L which is titanium stabilized ferritic stainless steel. These stainless steel tubes are used in all automotives for following applications due to lightness and strength, improved mechanical properties, improved corrosion resistance at high temperature and appearance. All tubes are manufactured from fully annealed strips on modern continuous forming mills with TIG welding process under inert gas atmosphere. Tubes are cut and end finished.

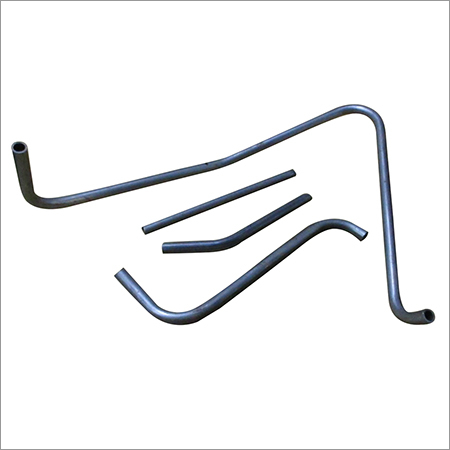

Applications

Automotive exhaust systems /Catalytic /converters / Mufflers

Our Size Range

O.D: 12.70 mm to 65.00 mm

Thickness: 1.0 mmto 2.0 mm

Length: As perthe requirements of customers/tailor made.

Tests Conducted

Tensile/Yield / Elongation / Flaring / Flattening / Bend / Hardness

Properties of 409L Grade material

Chemical Composition (% max) : C-0.03, Cr-10.5oto 11.75, Ti-6xC% to 0.75, Mn-1.00, P-0.040, 8-0030, Si-1.00, Ni-0.50

Mechanical Properties : Yield (0.2%) - 1 75MPa, Tensile - 380MPa, Elongation - 25%

Hardness(max) - 80H RB(175HV)

Physical Properties: Density - 7.74g/cm3, Electric Resistance 59X10-4 cm

Specific Heat(0-100C) - 0.11CaI/g C, Thermal Conductivity at 100C - 7.87CaI/cm.sec.C,

Thermal Conductivity at 500C - 7.29CaI/cm.sec.C, Young's Modulus - 201 x103 N/mm2

Coefficient of Elasticity - 201 x1 03 N/mm2, Coefficient of Thermal Expansion -12.3x10-6/C

TECHNICAL SPECIFICATIONS

| O.D. | Thick | Weight | O.D. | Thick | Weight |

| (mm) | (mm) | (Kg/Mtr) | (mm) | (mm) | (Kg/Mtr) |

| 12.70 | 1.0 | 0.29 | 35.00 | 1.2 | 1.01 |

| 12.70 | 1.2 | 0.34 | 35.00 | 2.0 | 1.64 |

| 12.70 | 1.5 | 0.42 | 38.10 | 1.0 | 0.92 |

| 12.70 | 2.0 | 0.53 | 38.10 | 1.2 | 1.10 |

| 15.80 | 1.0 | 0.37 | 40.00 | 1.0 | 0.97 |

| 15.80 | 1.2 | 0.43 | 40.00 | 1.2 | 1.15 |

| 15.80 | 1.5 | 0.53 | 40.00 | 2.0 | 1.88 |

| 15.80 | 2.0 | 0.68 | 42.75 | 1.0 | 1.04 |

| 19.05 | 1.0 | 0.45 | 42.75 | 1.2 | 1.24 |

| 19.05 | 1.2 | 0.53 | 44.43 | 1.2 | 1.08 |

| 19.05 | 1.5 | 0.65 | 44.43 | 1.2 | 1.29 |

| 19.05 | 2.0 | 0.85 | 44.43 | 2.0 | 2.10 |

| 21.40 | 1.2 | 0.60 | 45.00 | 1.0 | 1.09 |

| 21.40 | 1.5 | 0.51 | 45.00 | 1.2 | 1.30 |

| 22.20 | 1.0 | 0.53 | 45.30 | 1.0 | 1.10 |

| 22.20 | 1.2 | 0.62 | 45.30 | 1.2 | 1.31 |

| 22.20 | 2.0 | 1.00 | 45.30 | 2.0 | 2.15 |

| 25.40 | 1.0 | 0.61 | 48.30 | 1.0 | 1.17 |

| 25.40 | 1.2 | 0.72 | 48.30 | 1.2 | 1.40 |

| 28.58 | 1.0 | 0.68 | 50.80 | 1.0 | 1.24 |

| 28.58 | 1.2 | 0.81 | 50.80 | 1.2 | 1.48 |

| 28.85 | 1.0 | 0.69 | 54.45 | 1.0 | 1.33 |

| 28.85 | 1.2 | 0.82 | 54.45 | 1.2 | 1.58 |

| 28.85 | 2.0 | 1.33 | 60.30 | 1.0 | 1.47 |

| 31.75 | 1.0 | 0.76 | 60.30 | 1.2 | 1.76 |

| 31.75 | 1.2 | 0.91 | 65.00 | 1.2 | 1.90 |

| 31.75 | 1.5 | 1.13 | 65.00 | 1.5 | 2.36 |

| 31.75 | 2.0 | 1.48 | 65.00 | 2.0 | 3.12 |

Specifications Covered

- ASTM A249 / A249M : 2010 : Welded austenitic steel boiler, superheater, heat- exchanger and condensertubes.

- ASTM A268 / A268M : 2010 : Seamless and welded ferritic & martensitic stainless steel tubing for general service.

- ASTM A269 : 2010 : : Seamless and welded austenitic stainless steel tubing for general service.

- ASTM A270 / A27oM : 2010 : Seamless and welded austenitic stainless steel sanitary tubing.

- ASTM A312 /A312M : 2009 : Seamless, welded, and heavy cold worked austenitic stainless steel pipes.

- ASTM A409 / A409M : 2009 : Welded large diameter austenitic steel pipe for corrosive or high-temperature service.

- ASTM A554 : Welded Stainless Steel Mechanical Tubing.

- ASTM A688 / A688M : Seamless and welded Austenitic stainless steel feed water heater tubes.

- ASTM A778 : 2001 : Welded, unanealed austenitic stainless steel tubular products.

- ASTM A789 / A 789 M : Seamless and welded ferritic/austenitic stainless steel tubing for general service.

- DIN EN 10217-7 : 2005 : Welded steel tubes for pressure purposes-technical delivery conditions - part 7:stainless tubes.

- DIN EN 10296-2 : 2006 : Welded circular steel tubes for mechanical and general engineering purposes technical delivery conditions - part 2 : stainless steel.

- DIN EN 10312: 2005 : Welded stainless steel tubes for conveying water and other aqueous liquids.

- JISG 3459 : Stainless Steel welded and seamless tubes.

- JISG 3463 : Stainless Steel welded and seamless tubes for Boilers, Heat Exchanger, Condenser super heater.

- BS 3059 : Stainless steel tubes for Boiler and Super Heater.

- BS 3605 : Austenitic Stainless Steel Welded and Seamless tubes for pressure purposes.

- BS 3606 : Stainless Steel welded and seamless tubes for heat exchanger.

Company Details

Focusing on a customer-centric approach, KISSUI METALIKS & STEEL PVT. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Steel Pipes & Tubes in bulk from KISSUI METALIKS & STEEL PVT. LTD. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

20

Establishment

2009

Related Products

Explore Related Categories

More Product From This seller

Seller Details

New Delhi, Delhi

Managing Director

Mr. K. Chowdhury

Address

Corporate Address : GH-6/217, Meera Bagh, Paschim Vihar, New Delhi, Delhi, 110087, India

automotive tubes in New Delhi

Report incorrect details