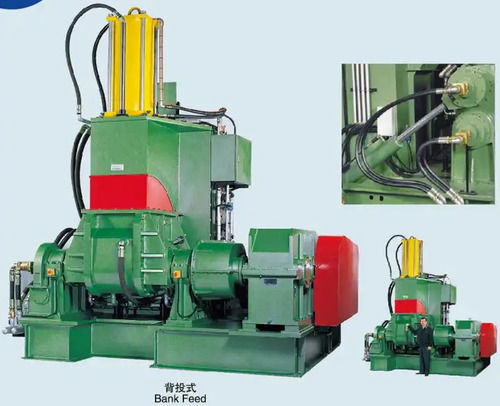

Abaliable In Multicolour Rubber Internal Mixer Machine

Price:

Get Latest Price

In Stock

Product Specifications

| Mixing capacity | 20L |

| Motor power | 37KW |

| Batching capacity | 15-25kgs |

| Mixing time | 4-8mins |

| Tilting angle | 110 |

| Machine size | 2600x1400x2600 |

| Machine weight | 4500 kg |

| Features | Robust construction, High fluency, Energy efficient, Longer life, Competitive price |

Product Overview

Key Features

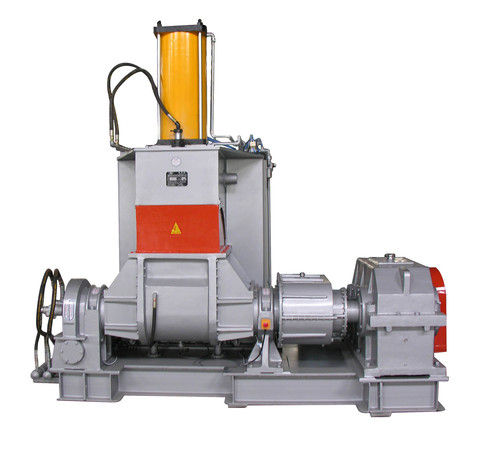

Rubber Internal Mixer Machine

Driven by technical excellence and wide distribution network, we are counted amongst the prime manufacturers, exporters and suppliers of Rubber Internal Mixer Machine. The offered machine is manufactured under the strict vigilance of our adept professionals using quality-tested components with the aid of ultra modern techniques. This machine is ideal for mixing of rubber. Available in several technical specifications, the provided Rubber Internal Mixer Machine can be availed from us at competitive price range.

Key Features:

- Robust construction

- High operational fluency

- Energy efficient

- Longer service life

- Competitive price

Technical Parameters:

| Mixing capacity(L) | 20L |

| Motor power | 37KW 6P AC |

| Material feeding | Front/back feeding |

| Temperature adjustment | Steam heating or water cooling |

| Mixing capacity per batching | About 15-25kgs/time |

| Mixing time | 4-8mins/batching |

| Rotor RPM | Front RPM/Behind RPM (according the require) |

| Temperature difference | 5 |

| gear reducer | ZLY250 |

| Tilting angle | 110 |

| Machine sizemm | 2600x1400x2600 |

| Machine weight (kg) | 4500 |

Public Equipment:

- Power 380V,50Hz 100kw

- Compressed Air6-8kg/cm 0.5cbm/min

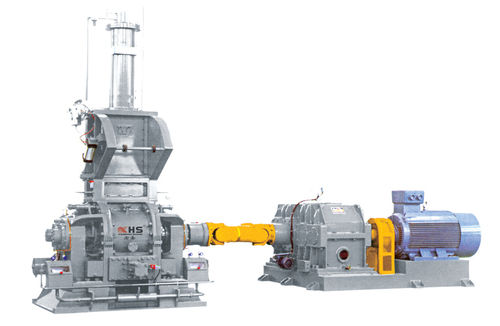

Machine Structure

Units:

- Machine Base Frame: welded by I steel and steel plate.

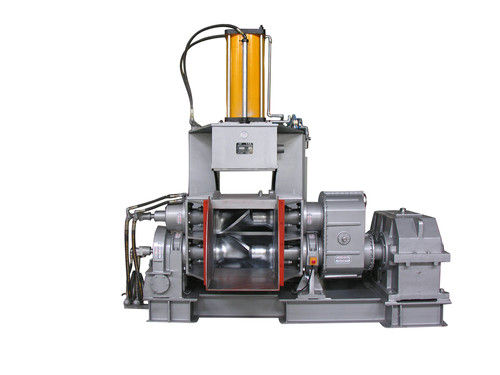

- Mixing Chamber: is welding by wear-resisting alloy steel,with special design of heating and cooling system.

- Mixing Shaft: the rotors are made of 20crMo forging units, the shaft is made of 20crMo whole set welding. Both rotors and shafts are hollow design which water or steam can get through.

- Bearing Base: made of ZG20 casting steel. Self-aligning bearing.

- Leakage-Proof Device: the whole mixing chamber is under special design and also adopts special material.

- The pressure gland is made of alloy steel,which is designed with small water pipe to cool it. During the mixing,it can provide pressure to the raw material.

- The air cylinder: with famous good quality sealers.

- Magnetic valve: Japanese CKD brand.

Discharge Device:

- Structure: worm gear structure to discharge the material.

- Tilting angle: 110degree

- Tilting motor: 1500W

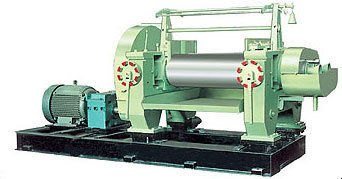

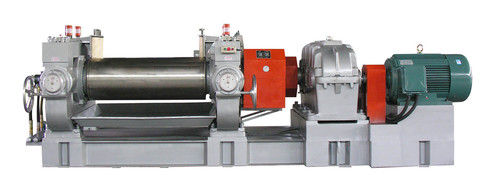

Transmission Drive:

- Main motor: 37kw,6P, AC

- Pulley belt: good quality rubber belt connect the motor and reducer.

- Reducer: model ZLY250.

- Ratio gear: the front and back rotor have speed difference.

Pipes:

- High pressure pipe.

- The mixing chamber, rotor, pressure lid all with small water cooling pipe. The in & out water pipe size is 1.

Electrical Control Cabinet:

- Floor stand electrical control cabinet.

- Standard electrical supply and device.

- Hongtai standard electrical cabinet or under customer special request.

- Automatic temperature setting,reveal and control.

- Time setting, thermometer, current meter and alarm.

Company Details

Focusing on a customer-centric approach, QUANZHOU HONGTAI MACHINERY CO.,LTD has a pan-India presence and caters to a huge consumer base throughout the country. Buy Dies & Moulds in bulk from QUANZHOU HONGTAI MACHINERY CO.,LTD at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier, Trading Company

Employee Count

10

Establishment

2015

Working Days

Monday To Sunday

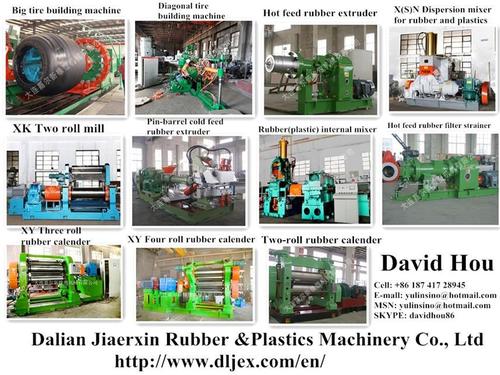

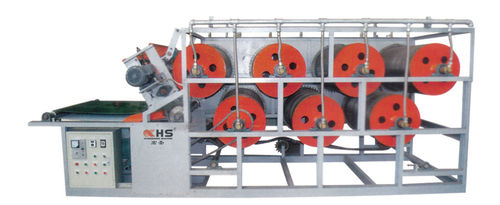

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Jinjiang, Fujian

Mr. Qinglin Lai

Address

2-503 Fulong Community, Xiyuan Street, Jinjiang, Fujian, 362200, China

rubber mixers in Jinjiang

Report incorrect details