Ribbon Blender - Stainless Steel, U-shaped Design, 1.5x1x1.25 Ft, 50 Liters Capacity | Efficient Mixing Of Dry And Semi-wet Powders, Quick Discharge Valve, Flame-proof Drive Option

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Ss/Ms |

| Dimensions | Variable |

| Capacity | 50-1000L |

| Motor | 3Ph Tefc |

| Speed | 50 Rpm |

| Bearings | Roller Bearings |

| Discharge | Quick Opening Valve |

| Features | Intensive Mixing, Versatile Design, Homogenous Blend, Quick Discharge, Efficient Mixing, Easy Operation, Durable Material |

Product Overview

Key Features

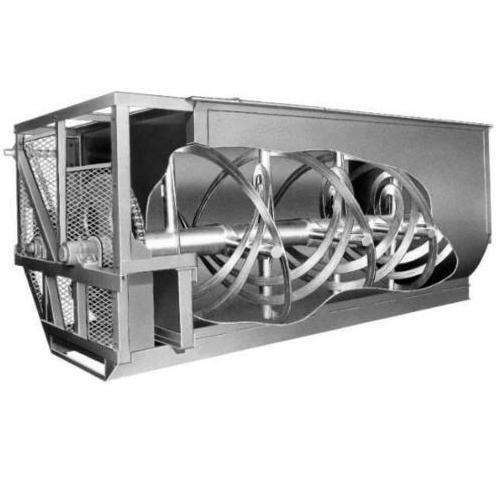

RIBBON BLENDER/ POWDER MIXER

APPLICATION:Suitable for homogenous mixing of dry powders of different bulk densities used in the Food, Mineral, Pharmaceutical, Paint & Chemical Industries. It is a simple versatile mixer, which can also mix semi-wet material. Ribbons of various designs are available to handle different materials. The mixer consists of a cylindrical shell inside which rotates a double helix shaft fitted with spiral inner and outer ribbons. During rotation of the shaft, the ribbons lift, convey and intermix the material to get a homogenous mass in short intervals. Discharge is from the bottom by a quick opening valve.

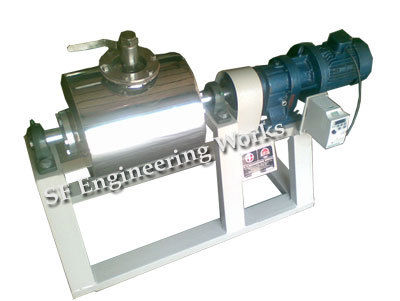

APPLICATION: For Intensive Mixing of wet and dry material used in the Food, Chemical, Pharmaceutical, Paint, Cement, Refractory, Adhesives, Building materials, Dyestuff and Allied Industry.

CONSTRUCTION: These mixers consist of a ~U~ shaped container [fabricated in M.S. or S.S.] inside which rotates a double helix ribbon shaft which intermixes the loaded material in three directions. The Blenders are highly efficient to ensure quick and thorough mixing of the material. The shafts are located in bearing blocks, which are complete with gland packing; roller bearings and oil seals for smooth and leak proof operation. A hinged type top cover with loading hopper and locking bolts is provided with the mixer. A screw type manually operated quick opening valve is provided at the central bottom position of the mixer. The mixer is supported on a heavy duty frame structure fabricated from ISMC sections and is free from vibrations.

DRIVE: MOTOR & GEAR BOX. The drive consists of a 3 Ph TEFC 415 V electric motor coupled to a horizontal worm reduction gear box complete with couplings, guards etc which run the ribbons at approx 50 RPM. This type of mixer is made up of S.S. or M.S. material. The sides of the blender are also made up of S.S. or M.S. material. It consists of a centre shaft of appropriate diameter and is either made of S.S. or M.S. material. The centre shaft is fitted with specially designed agitator blades in order to provide contra flow action. All the material in the mixer is constantly circulated from one end to the other. In larger mixer it is provided with inner and outer ribbons Sweeps maybe added to the outer ribbon to provide through clean out. The outer ribbons move ingredients towards the discharge while the inner ribbons constantly circulated material in opposite direction. The either ends of the vessel are provided with stuffing boxes on the shaft diameter. This stuffing box prevents leakage of material and also prevents material from entering into the bearings. The shaft is supported on heavy duty pedestals. The mixer is provided with a hopper and discharge. The drive consists of a suitable gear box coupled to the motor.

OPTIONAL: Flame Proof Drive, SS 316 Construction, Jacket Arrangement.

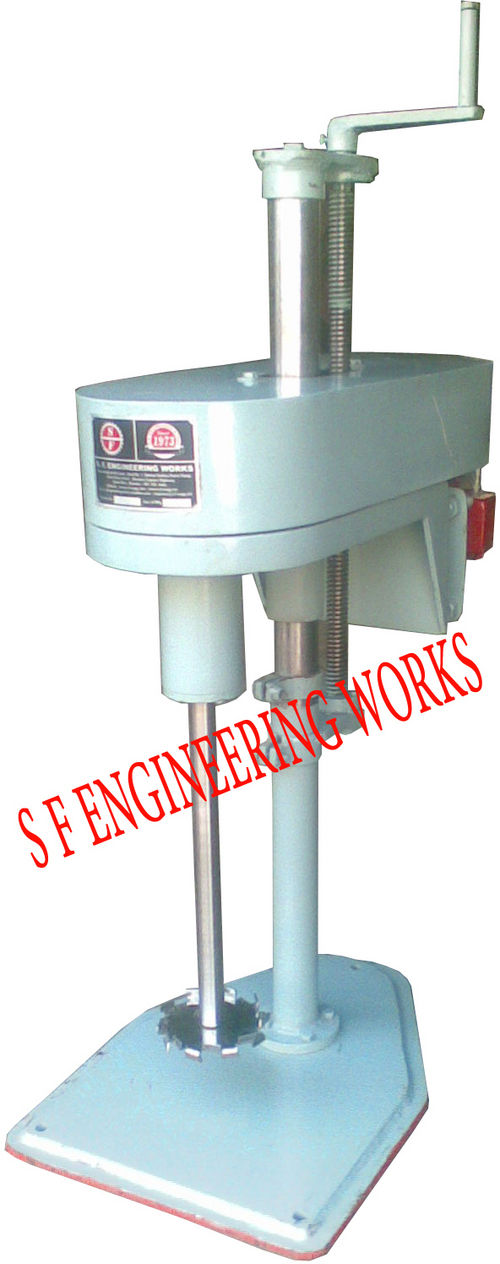

Tilting Arrangement.

MODEL

| CONTAINER DIAMENSION IN FT.

| VOLUMETRIC CAP IN LTRS

| HP

|

SFE- 2

| 1.5 x 1 x 1.25

| 50

| 1

|

SFE- 4

| 2.0 x 1.25 x 1.5

| 100

| 2

|

SFE- 8

| 3.0 x 1.5 x 2.0

| 225

| 3

|

SFE- 20

| 4.0 x 2.0 x 2.5

| 500

| 5

|

SFE- 40

| 5.0 x 2.5 x 2.0

| 1000

| 7.5

|

SFE- 60

| 6.0 x 3.0 x 3.5

| 1600

| 10

|

SFE- 80

| 8.0 x 3.0 x 3.5

| 2100

| 15

|

SFE120

|

| 3000

| 30

|

SFE200

|

| 5000

| 50

|

Note : Working capacity is 60 to 70 % of the total capacity.

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

15

Establishment

1973

Working Days

Monday To Sunday

GST NO

27ARUPS7370Q1ZE

Certification

ISO 9001 : 2015

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27ARUPS7370Q1ZE

Mira Bhayandar, Maharashtra

Proprietor

Mr Fayazulla Z. Sayed

Members since

21 Years

Address

SHANTA INDL. ESTATE, SHED NO-1, BEHIND DODHIA PETROL PUMP, W.E. HIGHWAY, KASHIMIRA-MIRA ROAD, Mira Bhayandar, Maharashtra, 401104, India

ribbon type blender in Mira Bhayandar

Report incorrect details