Reverse Osmosis Systems By Bee Gee Associates

Price:

Get Latest Price

In Stock

Product Specifications

| Flow Rate | 1.2-60 m3/h |

| Salt Rejection | 90-98% |

| Recovery Rate | 50-80% |

| Power Supply | 415V, 3ph, 50Hz |

| Pressure Vessels | FRP |

| Membranes | Polyamide |

| Pump | Stainless steel |

| Usage | Water purification for diverse industrial and commercial applications, including ultra-pure water production for electronics and pharmaceuticals, process water treatment in manufacturing plants, boiler feed water supply, beverage and food processing, drinking water treatment, wastewater treatment, biotechnology applications, and mineral water production. |

| Features | High rejection, Modular design, Easy install, Low energy, User friendly, Cost effective, Reliable system |

Product Overview

Key Features

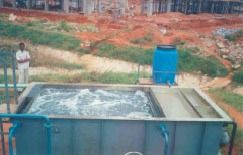

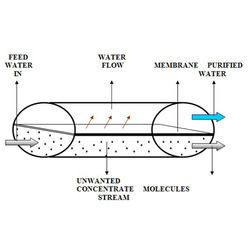

The INDION series of reverse osmosis systems provide

proven, highly reliable and cost effective treatment of

a wide range of brackish waters, Designed with

flexibility in mind, the series utilise state-of-the-art

spiral wound reverse osmosis membranes to suit a

given application. These systems can remove 90-98%

of total dissolved salts with minimum instruments and

controls.

Special Features

- Product flow rate 1.2 - 60 m3/h.

- Salt rejection ranges from 90 - 98% depending upon feed water composition.

- Product recovery ranges from 50 - 80% based on feed water composition.

- Electrical 415 V, 3 ph, 50 Hz.

- Concentrate discharge directed to drain at 'O' psi.

- Possible to hook up sophisticated instruments and controls

Advantages

- Modular design - capacity can be increased to suit requirements.

- Fully assembled skid, tested prior to shipment, ease of installation and beneficial use.

- Non-corrosive low pressure piping virtually maintenance free.

- Low on energy consumption.

- User friendly unit - does not require continuous monitoring.

Applications

- Ultra pure water for electronic industries

- Ultrapure water for pharmaceutical industries

- Process water for manufacturing plants

- Boiler feed water

- Beverage and food processing industry

- Drinking water

- Waste water

- Bio-technology

- Mineral water

Specifications

- Poly propylene cartridge housing pre-filter.

- FRP pressure vessels.

- Spiral wound membrane elements of polyamide type.

- 16 stainless steel multistage pump.

- TEFC pump motor.

- 316 stainless steel high pressure piping

- Low feed pressure switch for pump protection.

- High feed pressure switch for membrane & pump

protection.

- Motor starter with disconnect switch.

- Motor contactor with thermal overload protection.

- Sample valves for feed, product and concentrate.

- Concentrate check valve.

- Product check valve.

- Automatic feed shut-off valve.

Company Details

Focusing on a customer-centric approach, Bee Gee Associates has a pan-India presence and caters to a huge consumer base throughout the country. Get Water Treatment Plants from Bee Gee Associates at Trade India quality-assured services.

Business Type

Service Provider, Supplier, Trading Company

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Kanpur, Uttar Pradesh

Accepts only Domestic inquiries

Proprietor

Mr. B. S. Dhingra

Address

No.-117/H-1/282, Model Town, Pandu Nagar, Kanpur, Uttar Pradesh, 208005, India

domestic ro system in Kanpur

Report incorrect details