Silicon Carbide Pipe - High Density, 1.4-1.6x Od For High Temperature | Excellent Wear, Corrosion, And Thermal Shock Resistance

Price: 20 USD / Piece

Get Latest Price

Minimum Order Quantity :

100 Piece

In Stock

Product Specifications

| Usage | Used in medium frequency forging, various heat treatment electric furnaces, metallurgy, chemical industry, non-ferrous metal smelting and other industries. |

| Product Type | JX003 |

| Accessories | No |

| FOB Port | Dalian |

| Supply Ability | 100000 Per Year |

| Delivery Time | 10 Days |

| Sample Available | Yes |

| Sample Policy | Free samples available with shipping and taxes paid by the buyer |

| Packaging Details | Export Polywood Case |

| Main Domestic Market | All India |

Product Overview

Key Features

A

Application

Silicon carbide tubes are mainly used in medium frequency forging, various heat treatment electric furnaces, metallurgy, chemical industry, non-ferrous metal smelting and other industries. Widely used in metallurgical sintering furnace and intermediate frequency heating forging furnace. Length can be designed.

Features

1,A Moulding:A ColdA isostaticA pressing(CIP)

2,A Sintering:A GPSN/RSSN

3,A HighA strengthA andA goodA compactness

4,A LowA thermalA expansionA coefficient

5,A ExcellentA thermalA shockA resistance

6,A NoA wettingA byA moltenA aluminumA andA non-ferrousA metal

7,A GoodA corrosionA resistance

Advantage

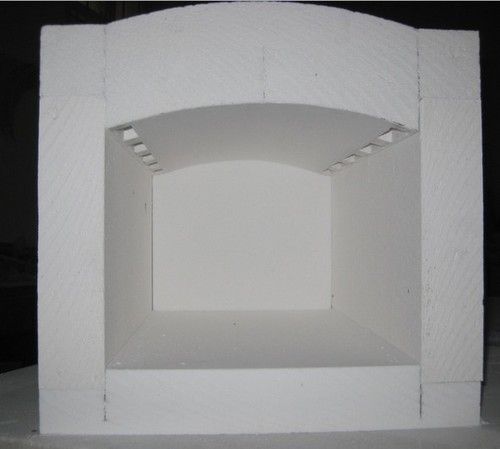

Silicon carbide tube with high density, impervious to water and air permeability, wear resistance, corrosion resistance, acid and alkali resistance, high temperature resistance, not easy to deformation, long life and other characteristics, can be used in copper, aluminum, zinc, alloy and other solutions! The inner diameter of the furnace hole through the silicon carbide tube should be 1.4 to 1.6 times the outer diameter of the cold end, and the furnace hole is too small or the filling in the hole is too tight, which obstructs the free expansion of the silicon carbide tube at high temperature and causes the rod to break. During installation, when the silicon carbide tube passes through the rod holes on both sides of the furnace wall, it should be freely rotated 360 degrees to prevent forced installation and beating. Before loading the rod, an iron tube with the diameter of the silicon carbide tube can be used for trial installation. The higher use temperature of silicon carbon tube is 1600, which can not be used for a long time. The normal operating temperature is 1450 degrees

Matter Needing Attention

1, silicon carbide pipe texture is hard and brittle, thread with limited elasticity, installation and disassembly should be fully careful attention,

2, life and the use of temperature is very much related, generally in 1300A AcA A A A A A A A 50A AcA A A A can run 1500 working hours.

3, the heated material can not contain too much water, otherwise it will affect the life of the silicon carbon tube

4, silicon carbon tube is not suitable for working in a protective atmosphere, such as hydrogen. Thus affect the life of silicon carbide tube.

5the selection of the surface load of the silicon carbon tube changes with the temperature, and the selection of the appropriate heating power can extend the life of the silicon carbon tube.

6, the silicon carbide tube should be cleaned between the internal and external furnace tubes before installation. Remove the debris between the threads of the silicon carbide pipe or that can cause short circuit, the conductive clip connection sheet should be tightly tightened, and the insulation sheet should be reliably insulated.

7, the installation can be electric oven, long-term need not use before also must oven,

8, spare silicon carbon tube should be placed in a dry, no atmosphere erosion place, to prevent aluminized end delixing.

SiC thermocouple protection tube RecommendedA Sizes

OD(mm)ID(mm)Length(mm)

168300-600

2212300-800

2816300-1200

3018300-1000

4525300-1000

Company Details

we provide sic heater mosi2 heater silicon carbide tube graphite sagger graphite heater exhibition carpet rib carpet bathroom carpet pvc floor

Business Type

Exporter, Manufacturer, Supplier

Employee Count

100

Establishment

1997

Working Days

Monday To Friday

Payment Mode

Telegraphic Transfer (T/T)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Liaoyang, Liaoning

Accepts only Domestic inquiries

Ceo

Mr Bai Ye David

Address

No.231, Zhonghua Street, Liaoyang, Liaoning, 111000, China

silicon carbide tubes in Liaoyang

Report incorrect details