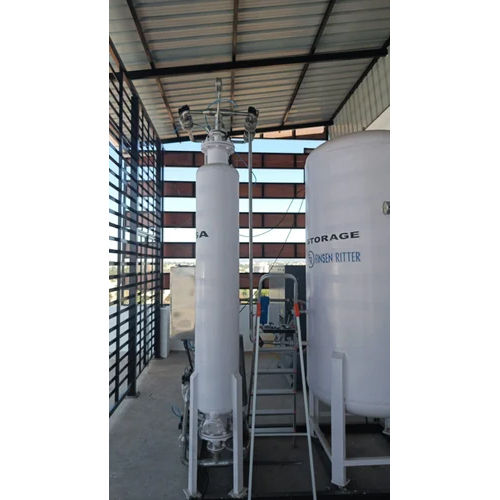

Oxygen Generator - Up To 20,000nmâ³/h Production Capacity, 25%~95% Purity Range, Full Automation And Minimal Space Requirements - High Reliability With Low Power Consumption

Price:

Get Latest Price

In Stock

Product Specifications

| Production Capacity | 20,000Nm³/H |

| Purity | 25%~95% |

| Pressure | 0.01~1.0Mpa |

| Temperature | Ambient |

| Material | Steel |

| Dimensions | Variable |

| Process | Psa |

| Features | High Purity, Full Automation, Cost Efficient, On-Site Production, Space Saving, High Reliability, Low Power Use |

Product Overview

Key Features

PLANT DATA

1.Production capacity : up to 20,000NmA /H

2.Purity : 25%~95% (v/v)

3.Pressure : 0.01~1.0MPa

4.Temperature :Ambient

PLANT FEATURES:

1. Full automation

2. Minimal space requirements

3. Independent on-site production

4. High reliability

5. Cost efficiency due to low power consumption, no injection water/cooling water.

BASIC PROCESS STEPS:

Our oxygen generation system employ the basic principle of air separation at ambient temperature

using Zeolite (a material that adsorbs nitrogen to leave a rich stream of oxygen).

The ambient(inlet) air is filtered before being compressed, moderately, bya blowerr system. The

pretreated air passes into a vessel containing molecular sieves to remove any moisture and/or CO2

and adsorbs the N2 while O2 passes through the vessel outlet. Before the adsorption capability of

the molecular sieves is exhausted the adsorption process is interrupted.

The saturated molecular sieve is regenerated by means of a pressure reduction below that of the

adsorption process. This can be achieved by a simple pressure release system (PSA-process) or

using vacuum pumps (VPSA-process). The resultant waste stream is vented to atmostphere.To maintain

a constant flow of O2 supply, a buffer tank is installed.

Company Details

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company

Employee Count

157

Establishment

2000

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Chengdu, Sichuan

Accepts only Foreign inquiries

Int'l Business Dept.

Mr. Robb Hu

Members since

12 Years

Address

No. 201, Sec. 1 Changcheng Road, Airport Economic Development Zone, Chengdu, Sichuan, 610207, China

oxygen gas generator in Chengdu

Report incorrect details