O-temper Cold Forming Aluminum Foil For Pharmaceutical Packaging - Coating Type: Pvdf

Price: 286625 INR / Ton

Get Latest Price

Minimum Order Quantity :

1 Ton

In Stock

Product Specifications

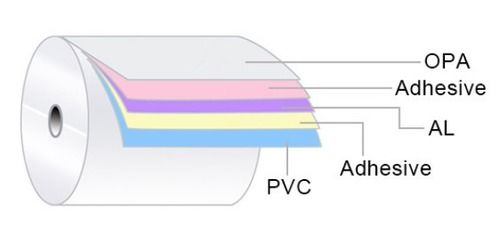

| Print Type | Flexo |

| Thickness | 0.025 Millimeter (mm) |

| Usage & Applications | Packaging of tablets, capsules, suppositories, etc. |

| Color | Customizable |

| Coating Type | pvdf |

| Eco Friendly | YES |

| Water Resistant | YES |

| Product Type | Pharmaceutical Foils |

| Material | Aluminum |

| Type | Roll |

| Alloy Condition | soft |

| Treatment | Coated |

| Reflectivity % | 85 |

| Temperature Range | 120 Celsius (oC) |

| Temper | Soft |

| Hardness | Soft |

| Width | 1000 Millimeter (mm) |

| Length | 16000 Millimeter (mm) |

| Size | 0.025*1000*16000mm |

| FOB Port | qingdao |

| Payment Terms | Telegraphic Transfer (T/T), Western Union, Letter of Credit (L/C) |

| Supply Ability | 200000 Per Year |

| Delivery Time | 20 Days |

| Sample Available | No |

| Sample Policy | Free samples available with shipping and taxes paid by the buyer |

| Packaging Details | Standard export wooden pallet packaging |

| Main Export Market(s) | Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa |

| Main Domestic Market | All India |

| Certifications | ISO 9001 |

Product Overview

Key Features

Company Details

Hongchang Aluminum is a large-scale modern aluminum processing enterprise integrating processing, manufacturing and scientific research of aluminum sheets, aluminum circles, aluminum sheets, aluminum strips and aluminum foils. The company has two main production bases, one located in Gongyi City, Henan Province and Xin'an Industrial Cluster Zone, Luoyang City, Henan Province, covering an area of 30,000 square meters. Hongchang Aluminum has more than 1,000 employees, 10 continuous casting production lines, and more than 20 other large-scale processing equipment, with an annual output of 200,000 tons. The company's products cover 1-8 series of aluminum alloy products of different sizes, including automotive aluminum sheets, household aluminum foils, anodized aluminum sheets, mirror aluminum sheets, packaging aluminum foils, aluminum foil PP covering materials, DOS oil-coated aluminum seals, cookware aluminum rings, and marine aluminum sheets. , double-zero aluminum foil, aluminum pattern sheets and other products.

Business Type

Manufacturer, Fabricator

Employee Count

99

Establishment

2020

Working Days

Monday To Friday

Payment Mode

Letter of Credit (L/C)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Zhengzhou, Henan

Mrs Hermione Miller

Address

No. 14, Business Outer Ring Road Zhengzhou, Henan, 450000, China

Report incorrect details