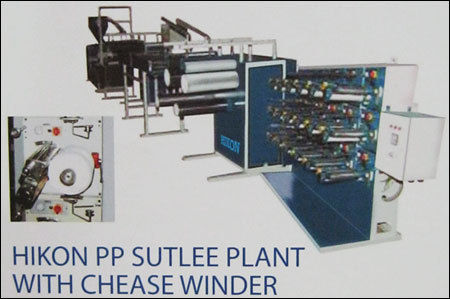

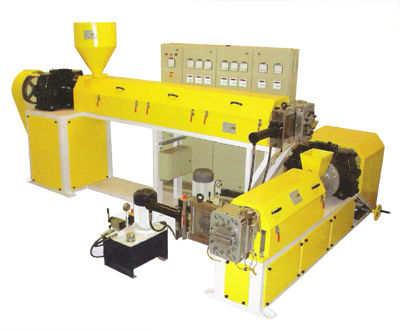

Mono And Multi Layer Sheet Plant - 3 Layer Pp/ld/hips Sheet Manufacturing , Suitable For 600 Mm Width & 0.4 Mm To 3.0 Mm Thickness

Price:

Get Latest Price

In Stock

Product Specifications

| Extruder Screw | 30mm, 90mm |

| Extruder Ratio | 26:1, 28:1 |

| Extruder Material | EN 41B |

| Sheet Die Width | 650mm |

| Sheet Thickness | 0.3-3.0mm |

| Chilling Plant | 5TR, 20TR |

| Production Capacity | 25-75 kg/hr |

| Features | High Output, Multilayer Sheets, Durable Design, Easy Operation, Precise Control, Cost Effective, Versatile Use, Customizable |

Product Overview

Key Features

KASTURI THREE LAYER PP/LD/HIPS SHEET PLANT SUITABLE FOR 600 M.M. WIDTH SHEET SIZE 0.4M.M TO 3.0M.M.

Dear sir,

We have pleasure to give you her under our lowest offer for above plant.

TECHNICAL DATA:

ETRUDER : ( 2 nos. : for out layer )

Screw : 30m.m

Ratio : 26:1

Material : En 41 B Gas nitride

Barrel : Plain

Material : En 41 B gas nitride

Heating zone : 3 zone

Barrel cooling blower : 2

Heating load : 6 kw.

Gear box : Helical size : 140

Motor : 5 H.P. AC

Drive : Ac frequency

Hopper : MS fabricated

SCREEN CHANGER : ( 2 Nos.) manual type

Heating zone : 1 ( for each)

Heating Load : 2 kw.

EXTRUDER : ( FOR MIDDLE LAYER )

Screw : 90 m.m

Ratio : 28:1

Material : EN 41 B Gas nitride

Barrel : plain

Material : EN 41 B Gas nitride

Heating zone : 6 zone

Barrel cooling blower : 5

Heating load : 25 kw.

Gear box : helical size: 140

Motor : 40 Hp.

Drive : AC frequency

Hopper : SS fabricated

SCREEN CHANGER : online type

Heating zone : 2

Heating load : 7 kw.

SHEET DIE ( T- TYPE)

Width : 650 m.m.

Working width : 600 m.m.

Min. thickness : 0.3 m.m.

Max. thickness : 3.0 m.m.

Heating zone : 3

Heating load : 7 kw.

POLISHING UNIT :

Nos. of roller : 5

Length of roller : 650 m.m.

Material : MS ground mirror finish & hard chrome plated

Motor : 5 hp.

Drive : Ac frequency

CHILLING PLANT :

One : 5 TR and other

: 20 TR. Chilling plant will be provided.

Heating load : 15 Hp.

NIP ROLLER :

Nos. of roller : one pair

Motor : 1 Hp.

Drive : Ac frequency

Gear : reduction gear

WINDER:

Station : 4

Drive : torque each station

CONTROL PANEL :

Nos. of zone : 19

Temp. controller : digital

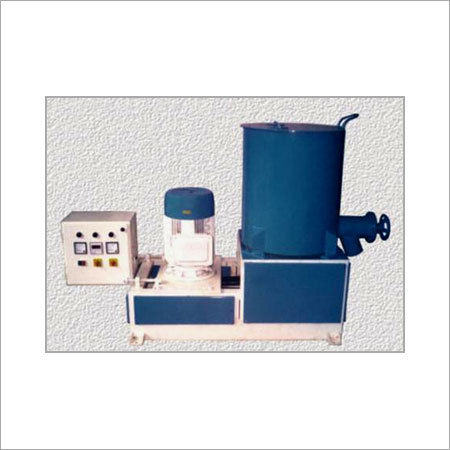

AGGLO MERATOR MACHINE :

Motoe : 25 HP

Capacity : 200 kg/hr.

GAS SUPPLY:-

Made by : India made

Pressorre capacity : 300 kg

Power : 5 hp.

Motor : 5 hp ac drive

AC FRIQUENCY DRIVE : for following ac motors.

50 HP. : for main extruder of 90m.m.

05 HP. : for main motor of 30 m.m

05 HP. : for main motor of 30 m.m

05 HP. : for polishing

01 HP. : for nip roller motor

# All Ac frequency drives synchronized by one master control.

# Main swwwwitch for panel

Production : 25 to 75 Kgs/ hour

( depend upon material & thickness of sheet)

Power requirement : 95 Hp.

Company Details

Focusing on a customer-centric approach, Aum Plast Extrusion has a pan-India presence and caters to a huge consumer base throughout the country. Buy Plastic Processing Machinery in bulk from Aum Plast Extrusion at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Employee Count

6

Establishment

1997

Working Days

Monday To Sunday

Payment Mode

Cash Advance (CA)

Related Products

More Product From This seller

Seller Details

Rajkot, Gujarat

Proprietor

Mr. Vijaybhai Madhani

Address

Plot No. FF-122, Samrudhdhi Bhavan, Gondal Road, Rajkot, Gujarat, 360001, India

Plastic Processing Machinery in Rajkot

Report incorrect details