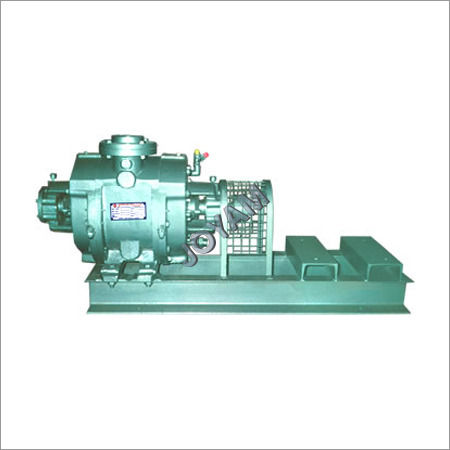

Mechanical Booster Systems

Price:

Get Latest Price

In Stock

Product Specifications

| Pump Type | Mechanical Booster |

| Material | Stainless Steel |

| Power Consumption | Variable |

| Volumetric Speed | High |

| Usage | Filtration, carbonation, condensation, metallurgy, casting, cooling, and soaking processes. |

| Maintenance | Low |

| Compliance | Industry Standards |

| Features | Low power, Low friction, High speed, Low maintenance, Energy efficient |

Product Overview

Key Features

We are an acclaimed name engaged in offering our precious clients superior quality Mechanical Booster Systems. The systems provided by us have very low pump friction losses therefore consumes less power for high volumetric speeds. These systems are manufactured by making use of optimum quality components and sophisticated technology in synchronization with set market standards. Our offered systems are widely used in filtration systems, carbonation CO2 compressors, condensation systems and metallurgy, casting, cooling & soaking processes. Moreover, we offer these Mechanical Booster Systems in various technical specifications.

Features:

-

Hassle free performance

-

Low maintenance

-

Low power consumption

-

Rust proof body

Mechanical Booster Systems

We are engaged in the production of energy efficient Vacuum Boosters. These pumps have very low pump friction losses and therefore, requires relatively low power for high volumetric speeds. These find usage in a variety of fields as follows:

-

Filtration systems

-

Carbonation CO2 compressors

-

Condensation systems

-

Metallurgy

-

Casting

-

Cooling

-

Soaking

-

Drying

-

Crystallization

-

Optical industries

-

Laboratory

-

Pulp and paper industries

-

Sugar industries

-

Power stations

-

Chemical industries

-

Food processing plants

-

Mineral processing plants

The advantages of these Mechanical Booster Systems are as follows:

-

Can be integrated with any installed vacuum systems such as steam ejectors, water ring pumps, oil sealed pumps and water ejectors

-

The vacuum booster is a dry pump, as it does not use any pumping fluid. It pumps vapor or gases with equal ease. Small amounts of condensed fluid can also be pumped

-

Vacuum Boosters are power efficient. Very often a combination of vacuum booster and suitable back up pump result in reduced power consumption per unit of pumping speed. They provide high pumping speeds even at low pressures

-

Boosters increase the working vacuum of the process, in most cases very essential for process performance and efficiency

-

It has very low pump friction losses, hence requires relatively low power for high volumetric speeds. Typically, their speeds, at low vacuums are 20-30 times higher than corresponding vane pumps/ring pumps of equivalent power

-

Vacuum boosters do not have any valves; rings, stuffing box, etc therefore do not demand regular maintenance

-

Due to vapor compression action by the booster, the pressure at the discharge of booster is maintained high, resulting in advantages such as low back streaming of prime pump fluid, effective condensation even at higher condenser temperatures and improvement of the back up pump efficiency

Company Details

Manufacturer of Vacuum Pumps, Twin Lobe Roots Blower, Mechanical Vacuum Booster, High Vacuum System, Oil Flooded High Vacuum Pump, Oil Seal High Vacuum Pump, Re Circulation System

Business Type

Manufacturer, Supplier

Employee Count

30

Establishment

1986

Working Days

Monday To Sunday

GST NO

24AABCJ9204H1ZS

Payment Mode

Cash Against Delivery (CAD)

Certification

ISO 9001 : 2015

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 24AABCJ9204H1ZS

Ahmedabad, Gujarat

Director

Mr. Amal Anil Mankad

Address

BNo. 704-B, Mahalay, Opp. Hotel President, Near Swastik Char Rasta, Navrangpura Ahmedabad, Gujarat, 380009, India

mechanical booster system in Ahmedabad

Report incorrect details