Liquid Rust Preventive Thickness: 100 Millimeter (Mm)

Price:

Get Latest Price

In Stock

Product Specifications

| Color | Amber |

| Viscosity | Variable |

| Film Thickness | 0.5-5 microns |

| Drying Time | 5-6 minutes |

| Usage | Rust prevention during manufacturing, storage, and after water-based machining. Vendor supplies and job-work component protection. |

| Application Methods | Dipping, Spraying, Brushing |

| Compatibility | Most materials |

| Features | Corrosion Prevention, Easy Application, Fast Drying, Low Consumption, Excellent Protection |

Product Overview

Key Features

We are the leading

organization in this domain, engaged in offering high quality Liquid Rust Preventive. It is processed

by adroit

experts in

adherence with set industry norms. Also, this is also examined by our quality

controllers on diverse parameters in order to ensure its effectiveness for

longer time period. This Liquid Rust

Preventive is used for corrosion prevention during manufacturing, vendor-supplies

or for dewatering, in-process storage, and rust prevention of components after

water based machining operations.

Features:

- Easy

to use - No

reaction with ant materials - Low

volatile content

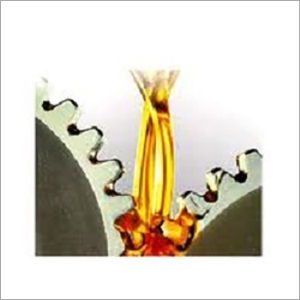

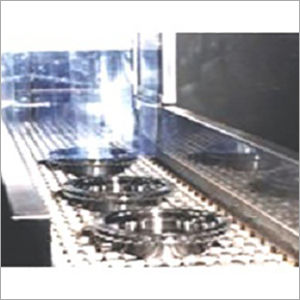

PRODUCT DESCRIPTIONIn Process rust preventivesare These SHORT TERM STORAGEAs | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

RUST PROTECTION AFTER MACHINING OPERATIONSAfter | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

VENDOR SUPPLIESDuring JOB-WORK COMPONENTSIn APPLICATION METHODDipping by far is the best method for establishing an even layer on the component. Other | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Features

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Physical, Chemical & Corrosion Prevention Properties

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PACKAGING AVAILABLE26 Liters Can & 210 Liters Barrel | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Company Details

Focusing on a customer-centric approach, PANKI METACHEM has a pan-India presence and caters to a huge consumer base throughout the country. Get Epoxy Flooring from PANKI METACHEM at Trade India quality-assured services.

Business Type

Manufacturer, Service Provider, Supplier

Employee Count

6

Establishment

1998

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

New Delhi, Delhi

Accepts only Domestic inquiries

Proprietor

Mr. Amit Ahuja

Address

130/GH-9, Paschim Vihar, New Delhi, Delhi, 110087, India

Report incorrect details