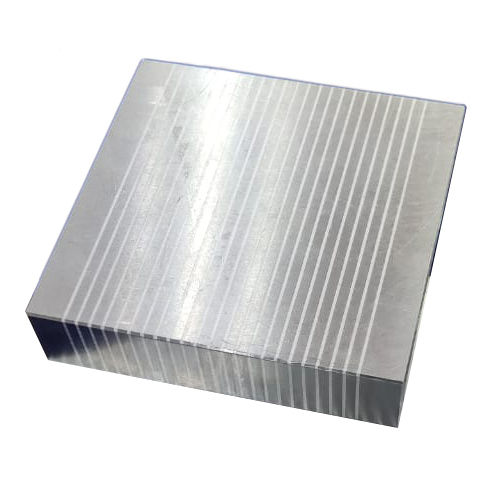

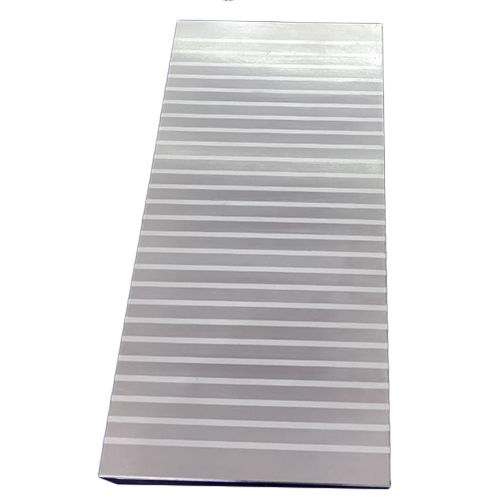

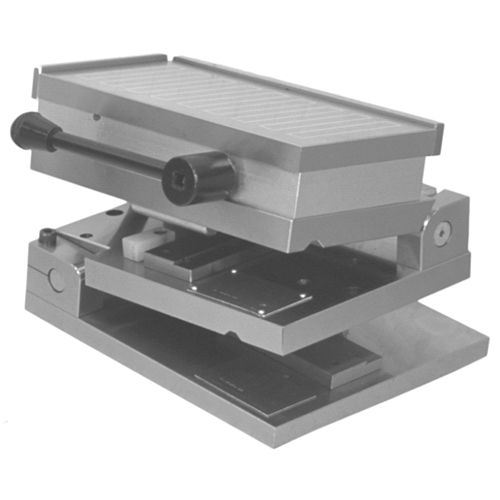

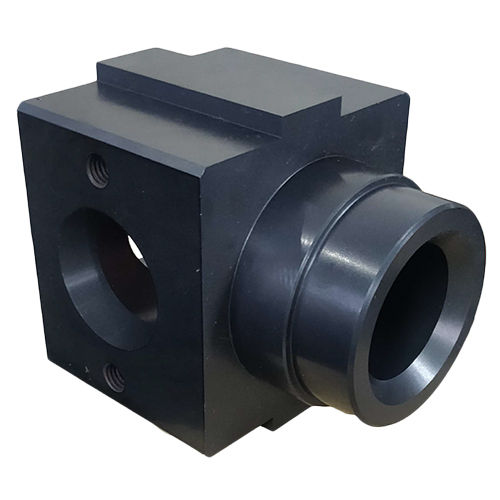

Industrial Blocks And Plates Surface Grinding Services

Price: 1000 INR / Unit

Get Latest Price

Minimum Order Quantity :

1 Unit

In Stock

Product Specifications

| Payment Terms | Cash in Advance (CID), Others |

| Sample Policy | Contact us for information regarding our sample policy |

| Main Export Market(s) | Asia |

| Main Domestic Market | All India |

Product Overview

Key Features

Surface grinding services for industrial blocks and plates involve precision machining to create flat, smooth surfaces on various materials. These services are crucial for achieving tight tolerances and high-quality finishes, especially for components that need to fit together seamlessly. Common applications include machinery manufacturing, automobile parts, and construction.

Industrial blocks and plates surface grinding services are crucial for various industries, including manufacturing, aerospace, and automotive. These services involve precision grinding to achieve high-quality finishes and precise flatness .

Types of Surface Grinding Services:

- Basic Surface Grinding: Suitable for small parts, using conventional machines, priced between 1,500 - 3,000.

- Precision Grinding: Achieves tight tolerances and fine finishes, ideal for intricate components, priced between 3,500 - 6,000.

- Blanchard Grinding: Ideal for large, flat surfaces, providing rapid material removal, priced between 4,000 - 8,000.

- Specialized Surface Grinding: Tailored for unique materials or specific customer requirements, priced between 6,000 - 12,000.

Benefits of Surface Grinding:

- Enhanced Surface Finish: Improves product quality and durability.

- Improved Tolerance: Ensures precise fit and function.

- Increased Durability: Extends product lifespan.

- Cost Efficiency: Reduces material waste and processing time.

Industries Served:

- Manufacturing: Produces high-quality components.

- Aerospace: Meets stringent quality standards.

- Automotive: Enhances performance and reliability.

- Tool and Die Making: Achieves precise tolerances.

Key Considerations:

- Material Requirements: Assessing material type and thickness.

- Grinding Techniques: Understanding various grinding methods.

- Equipment Capabilities: Evaluating machine precision and capacity.

- Cost Considerations: Balancing quality and budget constraints

Some notable service providers in India include

- Santhosh Industries (Bengaluru)

- Sri Vinayaka Tools (Bengaluru)

- VKTECH (Navsari)

- J K Engineering Works (Bengaluru)

- Shri Jayaveeraa Enterprises (Chennai)

Industrial blocks and plates surface grinding services are crucial for various industries, including manufacturing, aerospace, and automotive. These services involve precision grinding to achieve high-quality finishes and precise flatness .

Types of Surface Grinding Services:

- Basic Surface Grinding: Suitable for small parts, using conventional machines, priced between 1,500 - 3,000.

- Precision Grinding: Achieves tight tolerances and fine finishes, ideal for intricate components, priced between 3,500 - 6,000.

- Blanchard Grinding: Ideal for large, flat surfaces, providing rapid material removal, priced between 4,000 - 8,000.

- Specialized Surface Grinding: Tailored for unique materials or specific customer requirements, priced between 6,000 - 12,000.

Benefits of Surface Grinding:

- Enhanced Surface Finish: Improves product quality and durability.

- Improved Tolerance: Ensures precise fit and function.

- Increased Durability: Extends product lifespan.

- Cost Efficiency: Reduces material waste and processing time.

Industries Served:

- Manufacturing: Produces high-quality components.

- Aerospace: Meets stringent quality standards.

- Automotive: Enhances performance and reliability.

- Tool and Die Making: Achieves precise tolerances.

Key Considerations:

- Material Requirements: Assessing material type and thickness.

- Grinding Techniques: Understanding various grinding methods.

- Equipment Capabilities: Evaluating machine precision and capacity.

- Cost Considerations: Balancing quality and budget constraints

Some notable service providers in India include

- Santhosh Industries (Bengaluru)

- Sri Vinayaka Tools (Bengaluru)

- VKTECH (Navsari)

- J K Engineering Works (Bengaluru)

- Shri Jayaveeraa Enterprises (Chennai)

Company Details

In 1995, we, Rajshree Precision Pvt. Ltd., were formed in Faridabad, which is the largest industrial hub of the North India. A team of young and energetic engineers (TRTC=> An Indo-Danish Project) formed our company. For more than past 29 years, as a manufacturer, we have been designing, manufacturing, and delivering a range of tool room spares, die spare parts and standard accessories. We follow systematic and organized work approaches and procedures to ensure quality job works and attain complete satisfaction of customers. We work with the aim to provide the best products and services to customers. Specialization

Business Type

Exporter, Manufacturer, Service Provider, Supplier, Producer

Employee Count

80

Establishment

1995

Working Days

Monday To Sunday

GST NO

06AAMCR2601M1Z9

Certification

ISO 9001:2015

More Product From This seller

Seller Details

GST - 06AAMCR2601M1Z9

Faridabad, Haryana

Owner

Mr Mayank Gupta

Members since

2 Years

Address

Gali No. 7, H Block, Kheri Road, Bharat Colony, Faridabad, Haryana, 121002, India

Report incorrect details