Industrial Belt Filter Press Dimension(l*w*h): 1870*1710*2250 Millimeter (Mm)

Price Trend: 3500.00 - 16800.00 USD

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Material | Stainless Steel |

| Type | 100-200 |

| Weight (kg) | 3850 Kilograms (kg) |

| Computerized | No |

| Automatic | Yes |

| Ozone Generator | Yes |

| UV Sterilizer | Yes |

| Control System | PLC Control |

| Flow Rate | 100 |

| Motor | AC Motor |

| Dimension(L*W*H) | 1870*1710*2250 Millimeter (mm) |

| Warranty | 12 |

| Payment Terms | Letter of Credit at Sight (Sight L/C), Cash on Delivery (COD), Cash Against Delivery (CAD), Cash Advance (CA), Telegraphic Transfer (T/T), Cash in Advance (CID) |

| Supply Ability | 20 Per Week |

| Delivery Time | 1 Week |

| Sample Policy | Free samples are available |

| Packaging Details | Plywood case |

| Main Export Market(s) | South America, Africa, Asia |

| Main Domestic Market | All India |

Product Overview

Key Features

1. Products Introduction

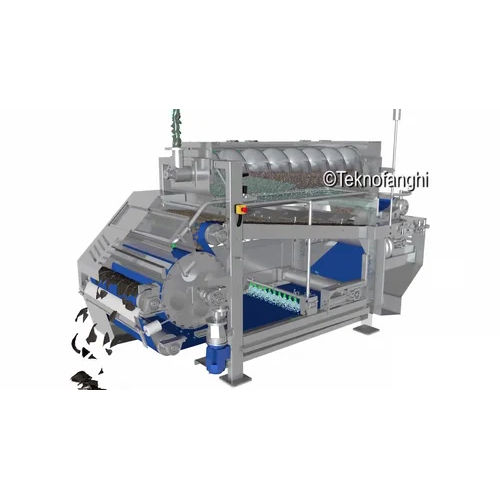

Belt filter press is mainly composed of driving device, frame, press roll, upper filter belt, lower filter belt, filter belt tesioning device, filter belt cleaning device, discharge device, gas control system. electric control system, etc. It is widely used for dewatering in tailings,sand washing sludge, construction piling, paper making industry sludge, textile industry sludge, printing and dyeing sludge, leather making industry sludge, mine beneficiation mud, food plant activated sludge, circuit board sludge, ceramics sludge, marble polishing sludge, electroplating sludge washed kaolin sludge, coal washing plant sludge, river channel sludge, chemical plant sludge, etc.

2. Main Features

1) The overall spray treatment technology adopted by the main frame can withstand acid and alkali corrosion for up to ten years.

2) The rubber roller is made of high-quality natural rubber which is resistant to acid, alkali and wear, and is processed into a full-sealing rubber roller (the surface of the rubber roller, the end surface of the rubber roller shaft, and the rubber roller shaft head are all covered with rubber).

3) using cylinder control to tighten and correct. The mesh belt rectification adopts triple correction protection device (pneumatic control; photoelectric control; stroke control) to ensure the normal operation of the mesh belt.

4) The main transmission device adopts frequency conversion speed regulation or mechanical stepless speed regulation.

5) System supporting process is unique, stable and reliable, using a combination of dynamic and static flocculation reactions, so that the use of pharmaceuticals is fully utilized, the customer operating costs are significantly lower than similar products.

6) The rubber roller is processed into a blank by using a seamless steel pipe with a through-shaft, and the load capacity of the rubber roller is greatly improved compared with similar products.

7) The bearing seat is made of our company's unique fully sealed steel castings, which are strong and durable. The bearings are made of high-strength double-row aligning cylindrical roller bearings, which are 2.7 times more durable than ball bearings.

8) The water tank and washing box are made of high quality PVC sheet, which is corrosion resistant and durable.

9) The sieve roller and bolt are made of high quality stainless steel.

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

80

Establishment

2002

Working Days

Monday To Friday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Chengdu, Sichuan

Sales Manager

Ms Selena

Address

No.146 of Konggang, 2nd Road, Southwest Airport Economic Development Zone, Shuangliu, Chengdu, Sichuan, 610220, China

belt filter press in Chengdu

Report incorrect details