Graphite Rotor - High Purity Moulded Graphite, 50-150 Mm Diameter | Enhanced Lifespan, Low Maintenance Costs, Improved Performance

Price Trend: 10-1000USD USD

Get Latest Price

Minimum Order Quantity :

1piece

In Stock

Product Specifications

| Material | graphite raw material |

| Application | industry field |

| Chemical Composition | carbon |

| Shape | rod |

| Hardness | 65 HSD |

| Density | 1.85 Kilogram per cubic meter (kg/m3) |

| FOB Port | Qingdao or Shanghai |

| Payment Terms | Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Western Union, Paypal, Days after Acceptance (DA) |

| Supply Ability | 100000ton Per Year |

| Delivery Time | 0.5 Months |

| Sample Policy | Contact us for information regarding our sample policy |

| Packaging Details | international standard packaging |

| Main Export Market(s) | Western Europe, Eastern Europe, North America |

| Main Domestic Market | All India |

| Certifications | Iso 9001:2008 international quality system certification |

Product Overview

Key Features

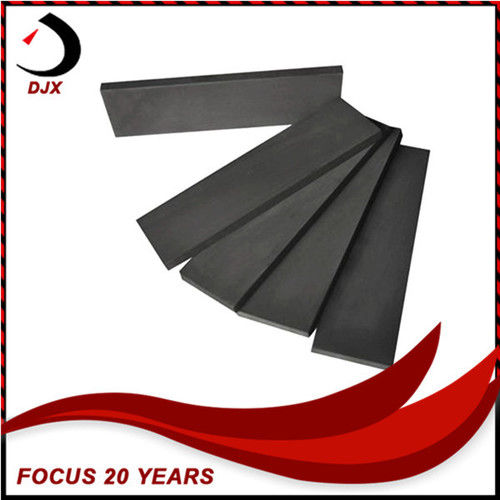

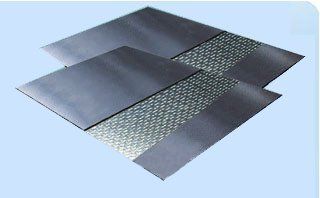

1. Material: impregnated with high purity moulded graphite and three special anti-oxidation treatments.

2. Product life: about 700 m2:55-65 days is greater than 1000 pieces: 25-35 days (depending on size and operation)

3. Applicable to aluminum, alloy, zinc and other casting industries, such as refining, removing slag, removing gas, blowing, etc.

4. The typical size - graphite rotor bar: Diameter: 50-150 - mm Length: 500-1200 - mm - graphite rotor head: Diameter: 100-300 - mm graphite rotor within the aluminum melt at about 750A C, to speed 200 r/min to 400 r/min under the condition of continuous work, the service life of the general requirements for a month or more.

My company rotor advantages:

1. Reduce the processing costA

2. Reduce the consumption of inert gas.

3. Reduce the aluminum content in the slag

4.Reduce labor costsA

5.Improve performance, longer replacement cycle

6.Improved reliability, lower maintenance costs.

Design and order of graphite rotor: because of the different specifications of graphite rotor used in each casting or casting line. Provided by the customer, the original design drawings and the physical and chemical parameters, and then, according to drawing combined with graphite rotor speed, the direction of rotation and with the relative position of liquid aluminum technology analysis.

Company Details

Focusing on a customer-centric approach, Wanhui Graphite Company has a pan-India presence and caters to a huge consumer base throughout the country. Buy Carbon & Graphite Products in bulk from Wanhui Graphite Company at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Pingdingshan, Henan

Mr Jack

Address

Baofeng County, Pingdingshan City, Pingdingshan, Henan, China

graphite sheets in Pingdingshan

Report incorrect details