Fully Automatic Plc Based Computerised Control

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel |

| Dimensions | Variable |

| Capacity | 100-250 Tph |

| Power | 53.5-100.5 Hp |

| Bins | Four |

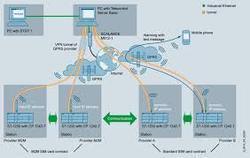

| Control | Plc Based |

| Mixers | Pugmill Type |

| Features | Automated Control, Precise Mixing, Efficient Operation, Real-Time Monitoring, High Output, Easy Operation, Durable Design, Remote Access, Reduced Waste |

Product Overview

Key Features

Fully Automatic PLC Based Computerised Control

- Aggregate flow rate in Kg/min through Load Cell in GTH

- Individual Bin, Water & Filler Flow controller

- Automatic real time synchronization of aggregate with water & filler

- Aggregate, Water & Mineral with totalizer

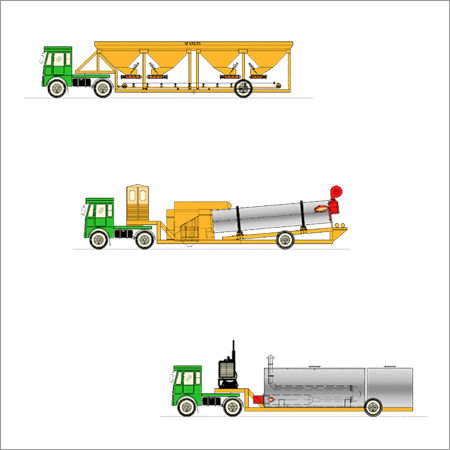

- FOUR BIN:

Each bin having independent belt conveying driven by AC variable speed

motors at the discharge end of the gathering conveyor with load cell

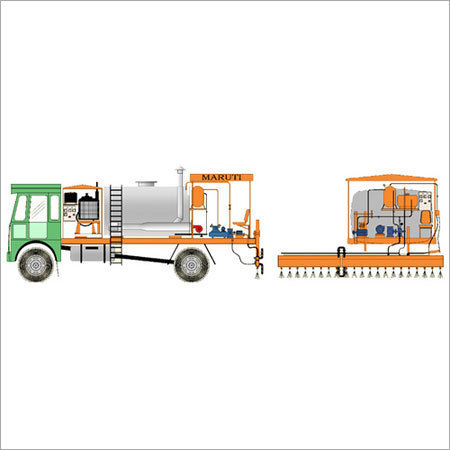

& single deck vibratory screen is provided for oversize removal. - PUGMILL/MIXER UNIT:

With slinger conveyor the mixer unit with oil bath type heavy duty

gearbox, paddle arm & tips are made of wear resistant NI-HARD

steel, Hydraulically operated discharge hopper. - LOADOUT CONVEYOR & HOPPER: This unit consists of a belt conveyor and hydraulically discharge hopper equipped with an auto on-off timer.

- FINE FILLER:

This unit is meant for adding fine filler in the mix. Filler is

supplied as per the required percentage to the mixing zone through a

screw conveyor driven by AC variable speed controls. Dust or filler

feeding into the hopper by manually or bucket elevator system as per

the requirement of customer. (Optional) - CONTROL PANEL ROOM:

A fully automatic Imported PLC based computerised feather touch control

panel with display screen and Imported AC Drive offers centralized

operation in an insulated dust proof control room. the plant operation

with synchronizing of water, aggregate and filler as per required

jobmix with production printer. (Air Conditioner is in buyer's scope.)

NAME OF THE UNIT | MODE MW | 1000 | 1500 | 2500 | LENGTH IN METER | WIDTH IN METER | HEIGHT IN METER | ||||||

CAPACITY @ TPH | 100 | 150 | 250 | 100 | 150 | 250 | 100 | 150 | 250 | 100 | 150 | 250 | |

FOUR BIN FEEDER | 40 MT | 60 MT | 80 MT | 11.00 | 12.00 | 13.00 | 2.30 | 2.50 | 2.70 | 3.10 | 3.35 | 3.60 | |

MIXER UNIT WITH INLET | 140 MT | 180 MT | 270 MT | 14.50 | 17.50 | 20.50 | 2.70 | 2.90 | 3.20 | 3.00 | 3.20 | 3.35 | |

DISCHARGE HOPPER | 2.0 MT | 3.0 MT | 4.0 MT | ||||||||||

WATER TANK | 10000 L | 15000 L | 2000 L | 5.50 | 6.25 | 8.25 | 2.70 | 2.70 | 2.70 | 2.80 | 2.80 | 2.80 | |

CEMENT FILLER | 0.50 MT | 0.75 MT | 1.20 MT | 3.80 | 3.80 | 4.25 | 2.30 | 2.30 | 2.80 | 4.20 | 4.50 | 4.75 | |

CONTROL ROOM | -- | -- | -- | 2.10 | 2.10 | 2.10 | 1.60 | 1.60 | 1.60 | 2.00 | 2.00 | 2.00 | |

GROSS TOTAL H.P. | 53.5 | 68.00 | 100.5 | Note : | |||||||||

Company Details

Focusing on a customer-centric approach, MARUTI INFRA EQUIPMENTS has a pan-India presence and caters to a huge consumer base throughout the country. Buy Road Construction Machinery in bulk from MARUTI INFRA EQUIPMENTS at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier, Trading Company

Employee Count

25

Establishment

1989

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Ahmedabad, Gujarat

Proprietor

Mr. Manish Dodia

Address

Plot No.40/2 Phase 4 Gidc Vatva, Ahmedabad, Gujarat, 382445, India

plc based system in Ahmedabad

Report incorrect details