Floating Guide System General Medicines

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel |

| Dimensions | Customizable |

| Capacity | 2 Tons/Hour |

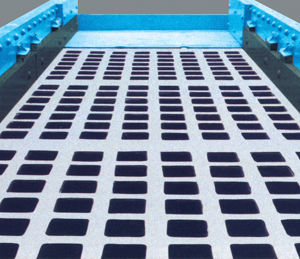

| Rollers | 9 Hard Chrome Plated |

| Nozzles | Inner And Outer Ss |

| Width | 300 Mm |

| Thickness | 20 Mm |

| Features | Precise Setting, Rugged Design, High Efficiency, Quiet Operation, Fine Solidification, Improved Quality, Enhanced Productivity, Easy Maintenance |

Product Overview

Key Features

Offered Floating Guide System is mainly used for fine setting of solidification of as cast strip. Owing to the expertise of our skilled professionals, we are able to manufacture, export and supply our customers high quality product that is demanded in the market due to its salient features given below. The product provided by us is manufactured by our adept professionals at our well-equipped production unit using supreme quality components as per the defined industry standards. Furthermore, this Floating Guide System goes through on certain parameters to ensure their performance and longer service life.

Features:

-

Power efficient

-

Rugged construction

-

Excellent performance

-

Noise less operation

Other Info:

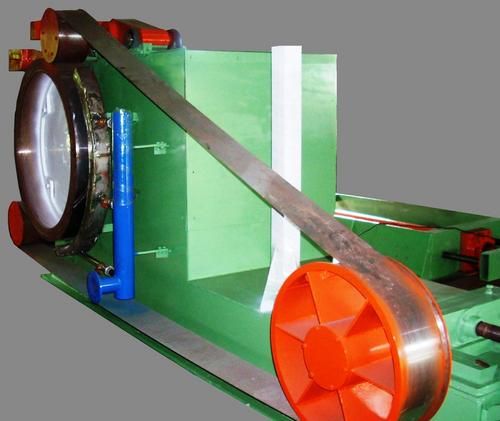

Face of the ring mold by an endless steel belt. The caster is provided with inner and outer SS spray nozzle. Each nozzle can be controlled individually for fine setting of solidification pattern of as cast strip. The belt guide rollers are pneumatically operated with pressure control valve to regulate the working pressure between ring mold and belt guide rolls. The width of as cast strip shall be 300 mm with a minimum thickness of 20 mm. The production capacity of the caster shall be 2 tons per hour.

The machine shall consist of the following

-

Strip caster assembly

-

Inner and outer cooling system

-

Belt wiper system

-

Metal tundish

-

Pneumatic system

-

Variable frequency drive system

Strip guide system

9 no hard chrome plated rollers mounted on pillow blocks are placed in front of strip caster to support as cast strip.

Floating guide system

Floating guide system is fabricated steel structure made out of 150 mm C channel with dancing pulley and counter weight arrangement acts as an accumulator between strip caster and hot mill to take care of synchronization between caster and rolling mill. The floating guide is to be placed in between rolling mill and shear cutter to give an intermittent feed to the cutter.

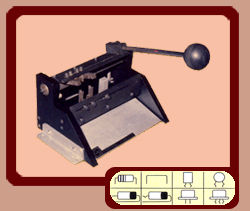

Strip hold down mechanism

During shearing operation of the strip it is essential to hold down as rolled strip during shearing operation . The strip hold down mechanism is a 5 roll system in which bottom three rolls are driven rolls and the top two rolls are pressure rolls which is operated by pneumatic cylinders. The drive to the bottom is by 5 HP motor with clutch brake mechanism through reduction gear box. All three rolls are coupled by chain and sprocket arrangement. The working of the strip hold down mechanism is via proximity switch which is mounted on a floating guide with variable length adjustment.

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

14

Establishment

2000

Working Days

Monday To Sunday

GST NO

24ABQPJ2589Q1ZR

Related Products

More Product From This seller

Seller Details

GST - 24ABQPJ2589Q1ZR

Vadodara, Gujarat

Proprietor

Mr N. C. Jain

Members since

3 Years

Address

E-28, GIDC, Manjusar, Taluka Savli, Vadodara, Gujarat, 391775, India

Processing Machines & Equipment in Vadodara

Report incorrect details