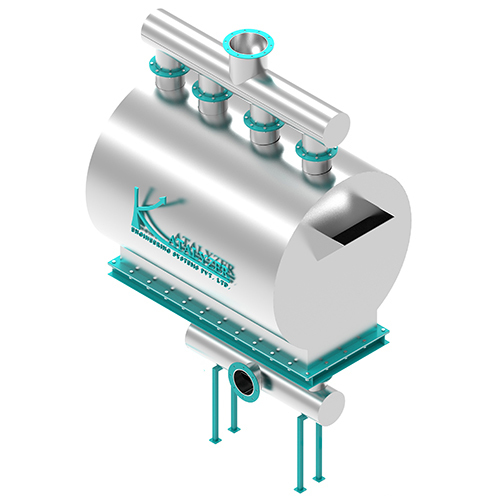

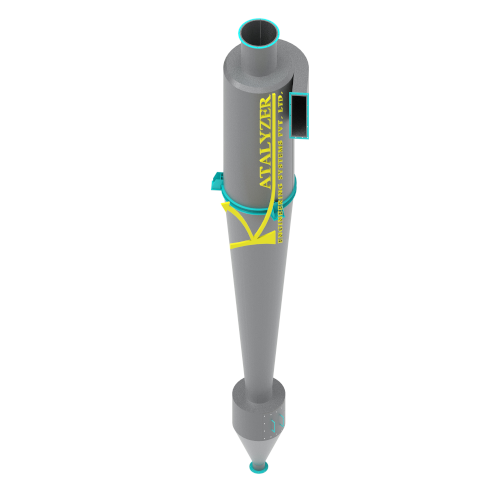

Cyclone Separator - Mild Steel / Ss304 / Ss316, 500 - 5000 Nmâ³/hr Air Flow | Efficient Dust Collection, Low Maintenance, Customizable Design

Price:

Get Latest Price

Brand Name :

Katalyzer Engineering Systems Pvt Ltd

In Stock

Product Specifications

| Efficiency | 85aEUR"95% for PM > 10 microns |

| Scrubber Type | Pre-scrubber or standalone (if part of multi-stage) |

| Usage & Applications | Dust collection, flue gas treatment, biomass plants |

| Power Source | External blower/fan required |

| Temperature | Up to 350AdegC Celsius (oC) |

| Display Type | Not Applicable |

| Measurement | Differential Pressure (if applicable) |

| Sensor Type | Optional (for advanced systems) |

| Orientation | Vertical |

| Automation Grade | Manual / Semi-Automatic (if integrated with controls) |

| Instruments Type | Optional (Pressure Drop Indicator) |

| Air Flow | 500 aEUR" 5000 NmA3/hr (Model dependent) |

| Product Type | Cyclone Separator |

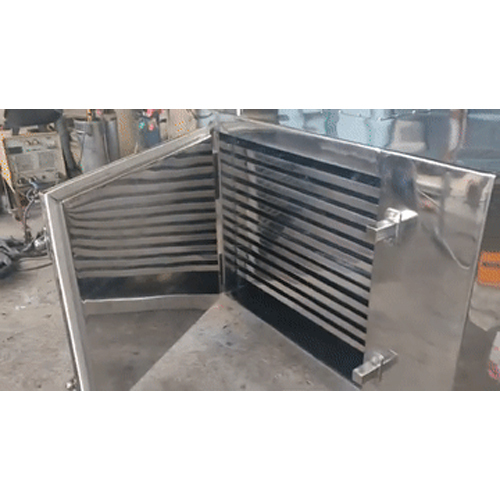

| Material | Mild Steel / SS304 / SS316 |

| Noise Level | < 70 dB (depends on connected fan) db |

| Reactor Thickness | 3aEUR"6 mm (customized based on pressure and material) Millimeter (mm) |

| Processing Time | Continuous Operation Hours |

| Capacity | 500 aEUR" 5000 NmA3/hr |

| Voltage | Not Applicable (Non-powered device) |

| Weight | Varies (typically 100aEUR"500 kg) Kilograms (kg) |

| Dimension (L*W*H) | Custom varies with flow capacity |

| Warranty | 12 Months standard |

| Surface | Epoxy Paint / Buffed Stainless Steel |

| FOB Port | Mumbai / Nhava Sheva (India) |

| Payment Terms | Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Others |

| Supply Ability | 10 Per Month |

| Delivery Time | 15 Days |

| Main Domestic Market | All India |

Product Overview

Key Features

Company Details

Katalyzer Engineering Systems Pvt. Ltd. is an emerging EPC solutions provider and industrial equipment manufacturer, delivering high-quality drying and processing systems for diverse industries. Established in 2023, we are driven by engineering innovation, precision manufacturing, and customer-centric solutions.

Our expertise lies in designing, manufacturing, and executing turnkey projects that enhance operational efficiency and productivity for our clients.

a

a End-to-End EPC Solutions

a State-of-the-Art Manufacturing Facilities

a Pilot Plant for Testing & Process Optimization

a Tailored Engineering for Maximum Efficiency

Our Vision

To become a global leader in industrial drying and processing solutions by offering innovative, energy-efficient, and sustainable engineering solutions.

Our Mission

To deliver high-performance engineering solutions tailored to customer needs.

To drive technological advancements in industrial drying and processing.

To maintain a strong focus on quality, safety, and sustainability.

Our Expertise

Katalyzer specializes in:

a EPC Services – Complete Engineering, Procurement & Construction solutions.

a Industrial Drying Systems – Spray Dryers, Spin Flash Dryers, and more.

a Heating Solutions – Indirect & Direct Hot Air Generators.

a Granulation & Mixing – Prilling Plants and Agitators.

a Process Optimization & Energy Efficiency Solutions.

a Pilot Plant Facility – Real-time testing & process validation for clients.

Our focus on custom engineering and precision manufacturing ensures that we meet the evolving demands of industries worldwide.

Our Infrastructure & Capabilities

Our advanced manufacturing facility is equipped with:

a State-of-the-art machinery for high-precision fabrication.

a In-house design & R&D team for innovative engineering.

a Quality assurance systems ensuring international standards compliance.

a Pilot Plant for Small-Scale Testing & Process Development.

We invest in continuous research & development to enhance efficiency and sustainability in our solutions.

Quality & Innovation

At Katalyzer, quality is non-negotiable. We implement rigorous quality control measures across all processes, from design to execution. Our R&D team continuously works on cutting-edge technologies to optimize energy efficiency, durability, and performance.

a ISO-Compliant Processes

a Precision Engineering & Testing

a Energy-Efficient & Eco-Friendly Designs

a Pilot Testing for Product Validation

Industries We Serve

Our expertise caters to a wide range of industries, including:

a Chemical Processing

a Pharmaceuticals

a Food & Beverages

a Agrochemicals

a Specialty Chemicals

Clientele & Projects

Even in a short span, we have successfully delivered customized engineering solutions for multiple industries. Our collaborative approach and commitment to excellence have helped us build a strong reputation in the market.

a Turnkey Spray Drying System for Chemical Industry

a Customized Prilling Plant for Agrochemical Processing

a Hot Air Generator Solutions for Pharmaceutical Drying

a Pilot Plant Testing for New Product Development

Business Type

Manufacturer, Service Provider, Supplier, Fabricator, Producer

Employee Count

10

Establishment

2023

Working Days

Monday To Sunday

GST NO

27AALCK3395E1Z9

Payment Mode

Others

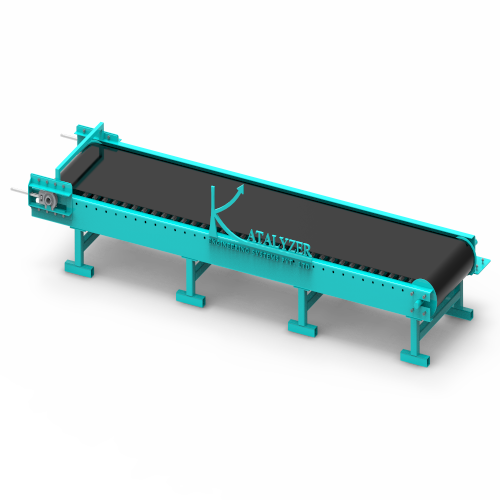

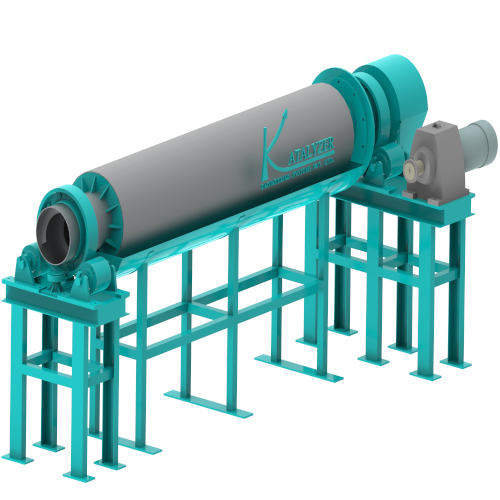

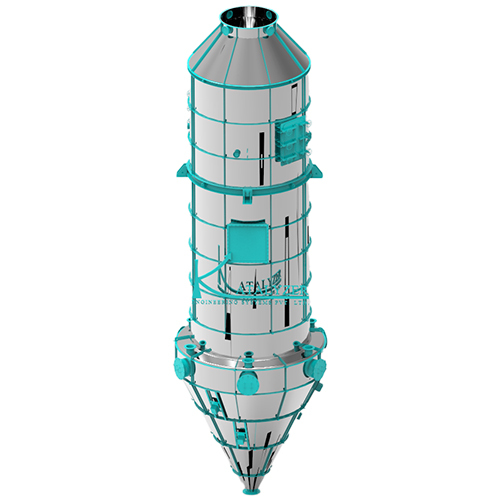

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27AALCK3395E1Z9

Dehu Road, Maharashtra

Proprietor

Mr Mandar Saraf

Members since

1 Years

Address

Gate No.1614, Patil Nagar, Dehu Alandi Road, Chikhali, Dehu Road, Maharashtra, 411062, India

Report incorrect details