Kumar Solvent Extraction Plant - Fully Automatic Design | Maximum Efficiency, Advanced Desolventizer Toaster, Continuous Processing, Special Rinsing System, Optimal Oil Recovery, Reduced Solvent Load

Price:

Get Latest Price

In Stock

Product Specifications

| Product Type | Extraction Plant |

| Dominant Color | Off-white |

| Capacity | Medium-Large Scale |

| Material | Stainless Steel |

| Dimensions | Variable |

| Power | Variable |

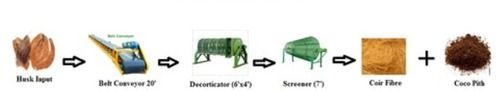

| Usage | Solvent extraction of oils from seeds, nuts, etc. |

| Safety Standards | CE compliant |

| Features | Continuous Process, High Efficiency, Automatic Operation, Solvent Recovery, Oil Extraction, Modern Design |

Product Overview

Key Features

Kumar Solvent Extraction Plants are known for efficiency, modern design and a continuous process of up gradation and other sales service at par with international standards

Salient Features for Kumar Extraction Plant

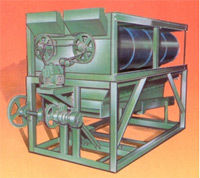

1. Extraction :

Circulation system is developed to have better solvent meal contact to have optimum recovery of oil. Better draining time is provided to reduce solvent contains in the extracted meal which will reduce the load on the D.T.

Special rinsing and back washing system to keep the band conveyor clean which will provide better percolation and avoid flooding i.e. better extraction.

Special fines separation system is provided to reduce fines in the final miscella which ultimately help to reduce load on the distillation system and will give solvent free oil with minimum fines and sludge.

This also help to avoid scale formation in the distillation system and help to minimize over heating of the oil and reduce utility consumption.

Specially designed condensation and recovery system help in maximum heat utilization and reduce load on condensation, which ultimately reduce solvent loss.

Company Details

Established in the year 1939, Kumar Metal Industries Pvt Ltd (KMIPL) is a globally established detail engineering & manufacturing organization with special expertise in Oil Mill, Solvent Extraction & Edible Oil Refining plants. Today we have our presence across 25 countries and serve over 500 customers

Business Type

Exporter, Manufacturer

Employee Count

250

Establishment

1939

Working Days

Monday To Sunday

GST NO

27AADCK0398K1Z7

Payment Mode

Letter of Credit (L/C)

Related Products

More Product From This seller

Seller Details

GST - 27AADCK0398K1Z7

Mira Bhayandar, Maharashtra

Accepts only Foreign inquiries

Director

Mr. Aditya Manaktala

Members since

21 Years

Address

Plot No. 7, Mira Co. Op. Indl Estate, W.e. Highway, Opp Amar Palace Hotel, Mira Road East, Mira Bhayandar, Maharashtra, 401104, India

Extraction Plants & Machinery in Mira Bhayandar

Report incorrect details