Welding System Computerized Pattern Maker

Price:

Get Latest Price

In Stock

Product Specifications

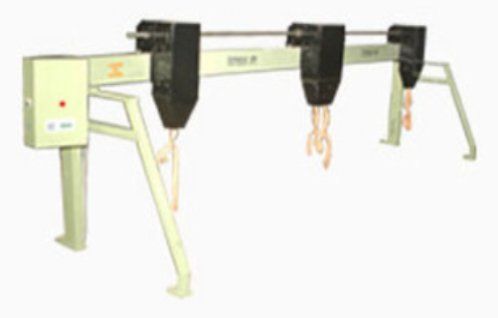

| Heads | Four Vertical |

| Hooks/Head | 72 |

| Speed | Up To 600 Rpm |

| Materials | Aluminum, Sheet Metal |

| Width | Double |

| Power | From Weaving Machine |

| Control | Electronic Panel |

| Features | Versatile Design, Efficient Operation, Easy Installation, Precise Patterns, User-Friendly Software, Compact Structure, High Speed, Durable Materials |

Product Overview

Key Features

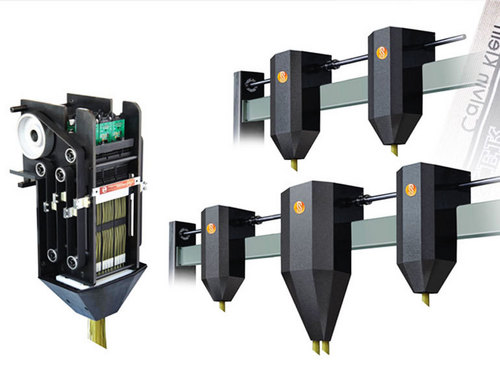

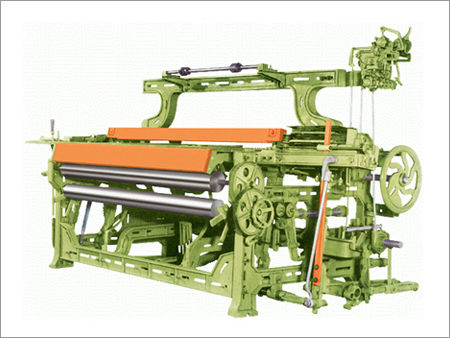

SUMA 288 is COMPUTERISED PATTERN MAKER designed for double width weaving machines. It has four vertical heads containing 72 hooks in each head for making patterns on selvedges. It is compact, efficient, virtual maintenance-free vertical model. Electronic panel is mounted on the CPM for smooth and hassle-free operation. It can synchronize the pattern making on any weaving machine up to 600 rpm. It can be installed on any Projectile, Rapier, Picanol, Dernier, Air jet weaving machine.

You can make any complex design in few minutes on users friendly SUMATEX

Design Software. Any font, any style, and size you can make on it. Length of monogram is no limit. You can write different monogram on all four side of both fabric. Two line display easily visible on machine gives you many information as during running machine like RPM of machine, length of fabric in meters from new beam start, running monogram, sequence of monogram (which will automatically change after completing the given length). Machine stop after monogram change is optional. Small panel on machine indicate the light if any problem arise in hardware, software.

Suma 600/288 is CPM designed for double width weaving machines. It has four vertical heads containing 72 hooks in each head for making patterns on selvedges. It is compact, efficient, virtual maintenance-free vertical model. Electronic panel is mounted on the CPM for smooth and hassle-free operation. It can synchronize the pattern making on any weaving machine up to 600 rpm. It can be installed on any Projectile, Rapier, Picanol, Dornier, Airjet, Waterjet, weaving machine.

You can run any number of hooks on machine like 12, 20, and 72. Industrial use data cassette is use to transfer the data from computer to panel. This data cassette is also use as a key for panel. No body can change the machine data without inserting the data cassette in panel.

Detail Features & Specifications:

- Suma 600/288 is a versatile and efficient model for single width weaving machine. This model has the

- 72 Hooks in each head for more precisive effective and eye-catching patterns, designs, motifs etc.

- Pattern Making adjustable to fabric width on selvedges or at the desired location of the fabric.

- Same or different monogram on fabric selvedges for discriminative fabric identification.

- Preprogrammed Change of monogram to facilitate automatic change of monograms without stopping the weaving machine.

- Compact, Vibrant & Heavy Duty structure for smooth and efficient pattern making.

- Mounted compact electronic panel requires no additional floor space to facilitate hassle-free operations ancillary to weaving.

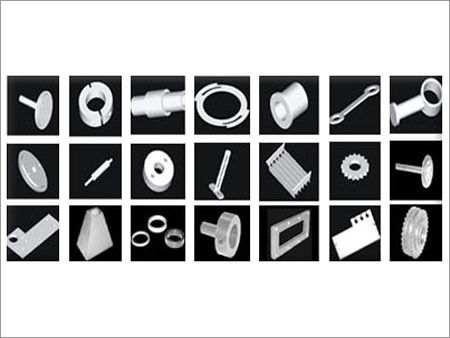

- High quality Industrial standard components / hardware are used to ensure that quality standards are consistently followed.

- High quality Aluminum & Sheet Metal coverings for robust structure.

- Easy installable in nick of time so that the weaving machines down time is minimized in installing CPM.

- Power supply from weaving machine only so that no additional power line is required in operating the CPM.

- Synchronizable capacity up to 600 rpm installable on any Projectile(Sulzer), Rapier, Picanol, Dornier, Airjet looms.

- Networking (Optional) to network all the CPM of a weaving unit to track the weaving activities on office computer.

Company Details

Focusing on a customer-centric approach, SUMATEX LIMITED has a pan-India presence and caters to a huge consumer base throughout the country. Buy Weaving Machinery in bulk from SUMATEX LIMITED at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Distributor, Supplier

Employee Count

180

Establishment

1998

Working Days

Monday To Sunday

GST NO

08AAFCS0342F2ZN

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 08AAFCS0342F2ZN

Bhilwara, Rajasthan

Managing Director

Mr. Surbhit Malu

Address

H-81, RIICO Extension, Pur Road, Bhilwara, Rajasthan, 311001, India

computerized pattern maker in Bhilwara

Report incorrect details