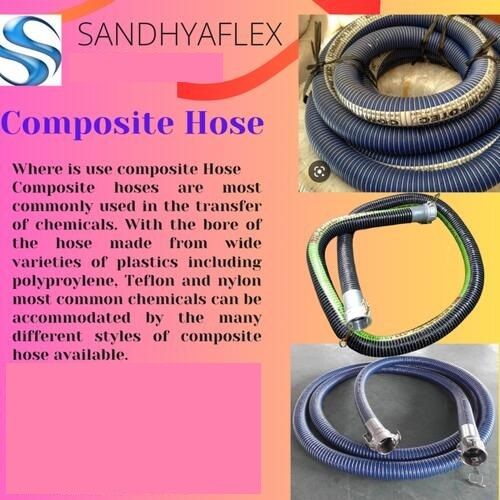

Composite Hoses By Sandhya Enterprises

Price:

Get Latest Price

In Stock

Product Specifications

| Usage | Industrial Use |

| Product Type | Composite Hoses |

| Shape | Round |

| Color | Grey |

| Supply Ability | 100 Per Day |

| Delivery Time | 7 Days |

| Sample Policy | Contact us for information regarding our sample policy |

| Packaging Details | Standard Packaging |

| Main Domestic Market | All India |

Product Overview

Key Features

Components of Composite Hoses:

1. **Inner and Outer Wire Helix:**

- Composite hoses typically have an inner and outer wire helix made of materials like stainless steel or galvanized steel. The helix provides structural support and prevents the hose from collapsing or kinking.

2. **Inner Layer:**

- The innermost layer comes in contact with the transported substance and is chosen based on the specific chemical compatibility requirements. Common materials include polyethylene, polypropylene, or PTFE (polytetrafluoroethylene).

3. **Barrier Layer:**

- In some composite hoses, a barrier layer may be added to enhance chemical resistance and prevent permeation. This layer acts as an additional protection against aggressive substances.

4. **Reinforcement Layers:**

- Composite hoses often include reinforcement layers made of materials like polyester, polyamide, or aramid fibers. These layers contribute to the hose's strength, flexibility, and resistance to pressure.

5. **Outer Layer:**

- The outer layer serves as protection against external factors such as abrasion, weathering, and UV exposure. Materials like polyethylene, polypropylene, or PVC may be used for the outer layer.

6. **Cover:**

- Some composite hoses feature an additional cover for added protection and durability. The cover material can vary based on the application and may include materials like rubber or thermoplastic.

### Key Features of Composite Hoses:

1. **Chemical Resistance:**

- Composite hoses are designed to resist a wide range of chemicals, making them suitable for the transportation of corrosive liquids, acids, and other aggressive substances.

2. **Versatility:**

- These hoses are versatile and can be customized to meet specific application requirements, including temperature, pressure, and chemical compatibility.

3. **Flexibility:**

- Composite hoses are flexible, allowing for easy handling and installation. This flexibility is crucial in applications where the hose needs to navigate around obstacles or through tight spaces.

4. **Lightweight:**

- Compared to some alternative materials, composite hoses are often lightweight. This characteristic is beneficial for applications that require portability and ease of handling.

5. **Resistance to Permeation:**

- Composite hoses are designed to minimize or prevent substance permeation, ensuring the integrity of the hose and preventing contamination of the transported material.

6. **Electrically Conductive Options:**

- Some composite hoses can be designed with electrically conductive layers to dissipate static electricity, reducing the risk of sparks in certain applications.

### Applications of Composite Hoses:

1. **Chemical Industry:**

- Transport of various chemicals, acids, and corrosive substances.

2. **Oil and Petrochemical Industry:**

- Transfer of oil, gasoline, and other petroleum products.

3. **Tank Truck Operations:**

- Loading and unloading of liquids in tank truck applications.

4. **Marine and Offshore:**

- Ship-to-shore transfer of fluids and chemicals.

5. **Railcar Loading and Unloading:**

- Safe transfer of liquids to and from rail tank cars.

6. **Agricultural Industry:**

- Handling and transfer of fertilizers, pesticides, and other agricultural chemicals.

7. **Food and Beverage Industry:**

- In certain cases, for the transfer of food-grade materials.

8. **Mining Operations:**

- Transport of slurries and other fluids in mining environments.

9. **Industrial Manufacturing:**

- Various applications in manufacturing processes where chemical resistance is crucial.

Composite hos

Company Details

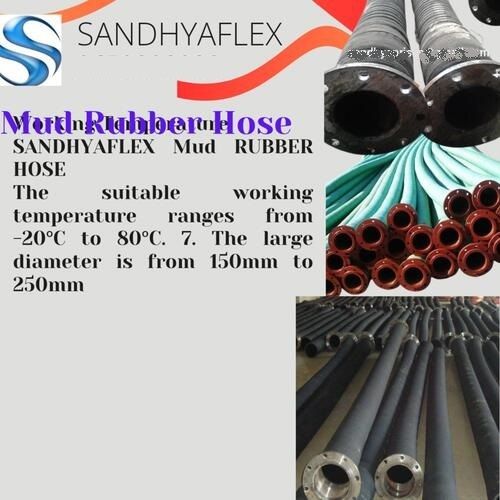

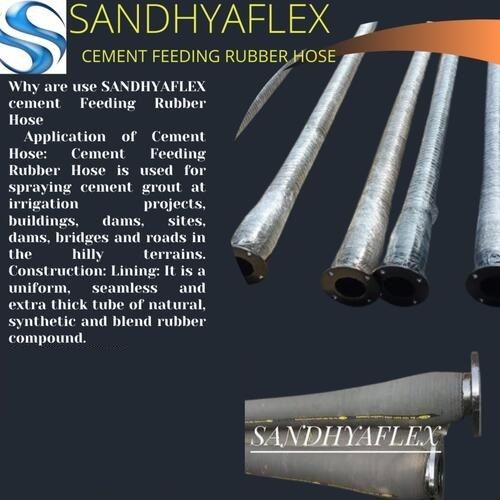

At Sandhya Enterprises, we pride ourselves on delivering high-quality construction products tailored to meet the diverse needs of our clients. With 25 years of experience and Exporting our Products like: Dam Gate seal, Drainage Spout, Cement Feeaading Rubber Hose in countries like Malaysia, Kenya, Ghana, Sri Lanka, and all over India, we have established ourselves as a trusted name in the industry, consistently exceeding customer expectations.

Our manufacturing expertise extends to Strip Seal Expansion Joint, Elastoameric Bridge Bearing, Dredge Delivery Rubber Hose, Slurry Rubber Hose, PTFE Pot Bridge Bearing, enabling us to provide comprehensive solutions for a wide range of construction projects. Whether it's Bridge, Road Construction, Cement Industries, Ready-mix Industries, Granite Industries, Mines Industries, Dredging Industries, Sectors like Power Plant, Water tank, our products are designed and manufactured to meet rigorous standards of durability, functionality, and aesthetic appeal.

What sets us apart is our unwavering commitment to innovation and customer satisfaction. We invest heavily in research and development, ensuring that our products remain at the forefront of technological advancements in the construction industry. We understand that every project is unique, and we work closely with our clients to provide customized solutions that address their specific requirements.

In addition to our cutting-edge manufacturing capabilities, we take great pride in our team of skilled professionals who are passionate about delivering excellence. Our dedicated team works tirelessly to ensure timely delivery, impeccable quality control, and exceptional customer service. We strive to build long-lasting partnerships with our clients based on trust, reliability, and mutual success.

I invite you to explore our comprehensive product portfolio and discover how Sandhya Enterprises can add value to your upcoming construction projects. I would be delighted to arrange a meeting at your convenience to discuss your specific needs and explore potential collaborations.

Business Type

Manufacturer, Supplier, Trading Company, Wholesaler, Retailer, Dealer, Fabricator, Producer

Employee Count

25

Establishment

2015

Working Days

Monday To Sunday

GST NO

36GNLPS1299P1ZS

Payment Mode

Cash Against Delivery (CAD)

Certification

ISO 9001:2015

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 36GNLPS1299P1ZS

Hyderabad, Telangana

Accepts only Domestic inquiries

Proprietor

Mr Mithilesh Chaudhary

Members since

4 Years

Address

Plot No.-24-1223/5/1, Ambedkar Nagar, Gajularamaram, Jeedimetla IDA, Hyderabad, Telangana, 500055, India

composite hoses in Hyderabad

Report incorrect details