Complete Set Automatic Butyl Reclaim Rubber Machine - Capacity: 16 Ton

Price: 10000 USD / Set

Get Latest Price

Minimum Order Quantity :

1 Set

In Stock

Product Specifications

| Type | Auto |

| Material | Steel |

| Capacity | 16 Ton |

| Computerized | Yes |

| Automatic Grade | Automatic |

| Control System | PLC Control |

| Cooling System | Water Cooling |

| Power Consumption | 400 Kilowatt (kW) |

| Voltage | 425 Volt (v) |

| Weight | 23000 Kilograms (kg) |

| Warranty | 12Month |

| FOB Port | qingdao port |

| Payment Terms | Telegraphic Transfer (T/T) |

| Supply Ability | 10 Per Month |

| Delivery Time | 50 Days |

| Sample Policy | Contact us for information regarding our sample policy |

| Packaging Details | Standard packaging |

| Main Export Market(s) | Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa |

Product Overview

Key Features

Natural recycled rubber desulfurization equipment (high temperature constant pressure plasticizer and high-speed mixingA desulfurization machine)

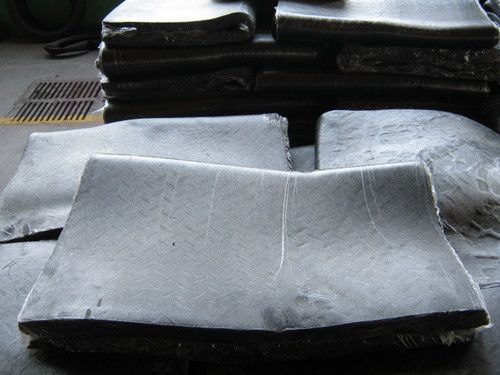

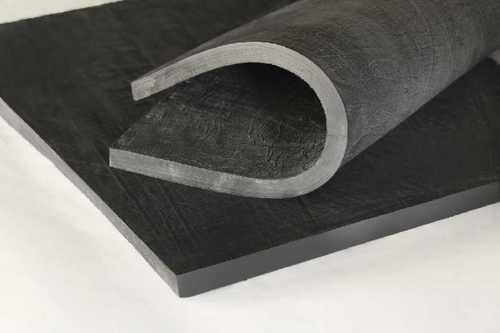

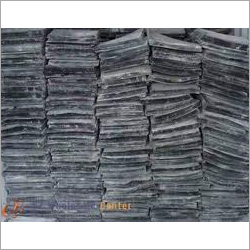

Butyl recycled rubber desulfurization equipment

Product Parameters

1. Product parameters:

Total power : 645KW

Capacity : 1200Kg/h

High mixing shaft speed : 468r/min.

High mixing tank working capacity : 400Kg.

Total plasticizing time of high stirring tank : 16min.

Cooling time of cooling tank A and B : 16min.

Working temperature : 220-250A C.

Total weight : 38.4 tons

Dimensions : 30000*9000*5000 mm (length * width * height)

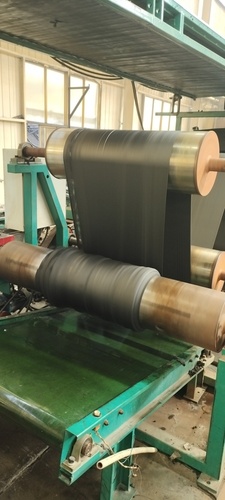

2. Product advantage ofA recycled rubber high-speed mixing machineA production line:

The machine uses high-speed mixingto generate heating throughout the automatic control, the operation is simple, the entire enclosed space operation, the production process has no odor, more environmentally friendly high temperature and normal pressure, no pressure, more safe rubber powder runs smoothly, is heated evenly, and the product performance is stable. Low power consumption, high output, 24-hour output of 25-30 tons or so.

High production is about 30 tons/24H.

Less power consumption, the use of high-speed mixingA to generate heat

Full automatic control, simple operation

The whole process of closed space operation, the production process has no bad smell and is more environmentally friendly

High temperature and normal pressure, no pressure is safer

The rubber powder runs smoothly, is heated evenly, and the product performance is stable.

Equipment basic structure:

The machine mainly consists of the following parts:

01. storage bin and feeding mechanism;

02. weighing bin and feeding mechanism;

03. High-speed mixing system;

04. Cooling system;

05. Cooling output system;

06. Environmental protection treatment system;

07.PLC automatic control system;

08.Power system;

09. Heating and insulation system.

Performance feature:

1. the machine has good environmental performance: I. The machine does not produce solid waste. II. No waste water discharge, the system cooling water is recycled through the cooling tower, not discharged. III. The waste gas is smoke-free, tasteless and dust free after treatment by electric heating organic waste gas thermal incineration device.

2.The machine has high safety performance: I. does not produce high pressure gas, liquid. II. Each thermal system is equipped with two sets of measurement and control systems to ensure safe operation within the set range. III. Each heating system adopts flame retardant aluminum silicate needle blanket for heat preservation; The insulation material has high temperature resistance (maximum temperature 126A C), the actual operating temperature of the system is: high stirring and insulation system temperature 240A C; Condensing evaporator 150A C; Electric heating organic waste gas thermal incineration device700A C. Therefore, the machine has good safety.

3.The machine has high efficiency and performance: I. High degree of automation, the whole system and the whole process are controlled by PLC (except manual testing). Low labor costs (1 person can monitor multiple sets of equipment). III. High production capacity and relatively low energy consumption. III. The output performance index is high, and the index is stable and does not rebound.

Waste gas treatment instructions:

1.Exhaust gas generation parts: I. high temperature exhaust gas in the high mixing body and the cooling tank. II. Medium temperature exhaust gas in the transition tank. III. Discharge of low-temperature exhaust gases in the auger

Company Details

Juxian Kaider Industry Co., Ltd. Was founded in juxian, Rizhao city, China, in 2010. We have two main factory, our factory produce reclaimed rubber machine, butyl reclaimed rubber machine, motorcycle tyre, tread rubber and cushion gum and tyre retreading machine and all kinds of retreading materials etc.

Our main products are reclaimed rubber machine, butyl reclaimed rubber machine, motorcycle tyre, Motorcycle Tyre Curing Machine, complete motorcycle tyres production line, Tread Rubber and Cushion Gum and Tyre Retreading Machine and we provide machine installation and staff training and machine maintain and retreading/reclaimed rubber production technology training.

We have several riching experiences quality checkers for the whole making cousre, the materials checking, the production processing checking, the finished goods checking, each step very strictly control.

By now we are steady cooperating very well with more than 20 countries and regions: Europe, USA, MID and South-America, Africa, MID-east, Southeast Asia etc. Welcome domestic and foreign new and old friends to visit the guide, business negotiations.

Business Type

Exporter, Manufacturer, Supplier, Wholesaler, Producer

Employee Count

50

Establishment

2009

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Rizhao, Shandong

Mr Jennifer Li

Address

No. 28, Juxain industry park, Juxian, Rizhao, Shandong, 276800, China

butyl reclaim rubber in Rizhao

Report incorrect details