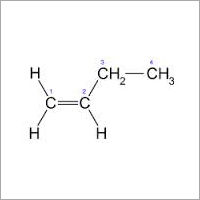

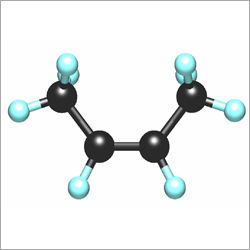

Cis-2-butene

Price:

Get Latest Price

In Stock

Product Specifications

| Purity | 99% |

| MolecularWeight | 56.11 |

| BoilingPoint | 3.72°C |

| Density | 2.46 kg/m³ |

| VaporPressure | 0.88 bar @0°C |

| FlammabilityRange | 1.7-9.7% |

| SpecificVolume | 0.407 m³/kg |

| Features | High purity, Versatile chemical, Wide applications, Reliable source, Cost-effective |

Product Overview

Key Features

| Product information | |

| Quality code | 2.0 . |

| Purity % volume | >=99 |

| Impurities ppm | |

| (where nothing else stated) | |

| trans-2-Butene | 0.5% |

| O2 | 10 |

| N2 | 50 |

| General information Filling pressure at 15 C, bar: | 1.5 |

| Material recommendations: | Gas: No restrictions |

| Liquid: Avoid plastic and rubber. | |

| Characteristics | |

| Highly flammable, liquefied, colourless gas. | |

| Health risks | |

| Asphyxiating. | |

| Transport | |

| ADR Class 2, 3(b). | |

| Physical data | |

| Molecular weight: | 56.11 56.11 |

| Boiling point at 1.013 bar, C: | 3.72 |

| Density (1.013 bar, 15 C) kg/m3: | 2.46 |

| Vapour pressure at 0 C, bar: | 0.88 |

| 20 C, bar: | 1.8 |

| Flammability range in air, % (volume): | 1.7-9.7 |

| Specific volume (1.013 bar, 15 C), m3/kg: | 0.407 |

| Source | |

Almost all commercially produced butenes are obtained as by-products

| |

| The butenes obtained are withdrawn as a mixture from the C4-fraction. From this mixture butadiene and butanes are separated by extractive distillation. The remaining butenes cannot be separated by mere distillation because their boiling points are too close together. | |

| In a first step iso-butene is isolated either by etherification with methanol to form methyl tert-butylether (MTB), or by hydrating iso-butene to tert-butanol (TBA). In this step all other C, components in the mixture remain unchanged. MTB and TEA can then be split by reversing synthesis to produce high purity iso-butene. Once the iso-butene content has been reduced, recovery of high purity 1-butene is possible by fractionation. The remaining 2-butenes can be separated by molecular sieve absorption methods. | |

Other commercial processes that are sometimes used to produce specific isomers or mixtures of butenes or both, either directly or as by-products, include:

AU or any of them may become useful feedstock sources should the need arise. | |

Applications

| |

Company Details

Focusing on a customer-centric approach, SPECIAL GAS & EQUIPMENT SOLUTIONS PVT. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Industrial Gases in bulk from SPECIAL GAS & EQUIPMENT SOLUTIONS PVT. LTD. at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Employee Count

5

Establishment

2010

GST NO

19AAOCS4059G1ZW

Related Products

More Product From This seller

Seller Details

GST - 19AAOCS4059G1ZW

Kolkata, West Bengal

Director

Mr. Saibal Basu

Address

Plot No. BJ- 133, Sector II, Salt Lake, near ICICI bank, Kolkata, West Bengal, 700091, India

Industrial Gases in Kolkata

Report incorrect details