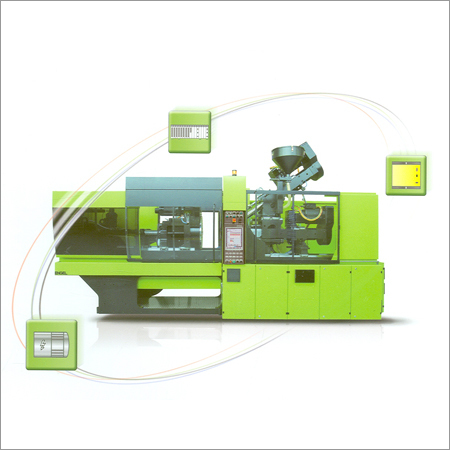

Automatic Pet Blow Machine For Wide Mouth Jars

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel, Electric Components |

| Dimensions | Variable |

| Power | 34-100Kw |

| Production Rate | 1800-5200 Bph |

| Cavities | 2-4 |

| Max Pressure | 40 Kg/Cm |

| Weight | 5700-7000Kg |

| Features | Auto Orientation, Close Loop Heating, Servo Stretching, Quick Mould Change, User Friendly Interface, Energy Saving Design |

Product Overview

Key Features

Key Features:

Preform Handling:

- Auto Orientation depending on Preform Design.

- Loading on Oven Mandrels using Turret Wheel System.

Heat Conditioning:

- Close Loop Heating System; Auto Preform Temperature Control.

- Variable Speed Ventilators for accurate Chamber Temperature Control.

- Modular Heating System for Quick Maintenance of Heating Lamps.

- Replica Jig for simpler, faster and accurate positioning of Heating Lamps.

- Neck Protection throughout Oven from Heating.

- Dual Neck Cooling using Air + Chilled Water.

Stretching:

- Servo Stretching in Dual mode with synchronization with Mould Clamp, to reduce cycle time.

- Precise Control of Preblow (Primary Blow) and Blowing (Final Blow).

- Reduced Frictional and Inertia losses.

Mould Clamp:

- Electrical Mould Clamp using Servo system.

- Mould Compensation for Faster and Positive Locking without vibration.

- Synchronized with Stretching Functions.

Reduced Change Over:

- Quick Mould Change Over System.

- No Lifting Equipment required.

- No need to remove and re-fit Cooling Lines.

- Less Time and Efforts.

- Quick Mandrels Change Over for Oven and Blowing unit.

Protection and Controls:

- User Friendly Interface using Graphical Touch Screen.

- Stand Alone Man-Machine Interface.

- Safety switches for all Open able Guards.

- Earth Leak Protection for Equipment and Human Safety.

- Over Load Protection for all equipments and Main Supply.

- Individual Circuit Breakers for all Electric Functions.

- Group Pressure Control for all Pneumatic Functions.

- Temperature Control for Electric Panel.

- No Low Pressure Air Required. Blowing Air is recovered and re-collected to be used for Machine Operations, and fed back to Booster Compressor.

- Heating Lamps adjustable to go closest to Preform, to reduce attenuation loss.

| Application | Bottles | Wide Mouth Jars | |||||

| Model | Unit | Series II | Series I | Pristine | |||

| SPSB 02-2- Series II | SPSB 04-2-Series II | SPSB 02-2 | SPSB04-2 | SP Pristine 02-5 (W) | SP Pristine 04-2 (W) | ||

| Production Rate | BPH | 2600 | 4800 | 2000 | 4000 | 1800-3000 | 3600-5200 |

| No of Cavities | no | 2 | 4 | 2 | 4 | 2 | 4 |

| Max Container Dia | mm | 115 | 115 | 115 | 115 | 170 | 100 |

| Max Container Height | mm | 350 | 350 | 350 | 350 | 350 | 350 |

| Max Container Volume | Liters | 2 | 2 | 2 | 2 | 5 | 2 |

| Max Neck Size | mm | 32 | 32 | 32 | 32 | 120 | 83 |

| Pitch in Oven | mm | 63.5 | 63.5 | 63.5 | 63.5 | 152.4 | 114.3 |

| Max Blowing Pressure | kg/cm | 40 | 40 | 40 | 40 | 40 | 40 |

| Length (A+B) | mm | 5600 | 5900 | 5600 | 5900 | 8400 | 9000 |

| Width (C) | mm | 2800 | 4000 | 2800 | 4000 | 2550+3000 | 2550+3000 |

| Height (D) | mm | 2400 | 2700 | 2400 | 2700 | 1950 | 1950 |

| Height (E) | mm | 3300 | 3500 | 3300 | 3500 | 3600 | 3600 |

| Weight (approx) | kg | 5700 | 7000 | 5700 | 7000 | ||

| Utilities Electrical | |||||||

| Total Load | kW | 34 | 65 | 34 | 65 | 100 | 100 |

| Heating Load | kW | 23 | 46 | 23 | 46 | 72 | 72 |

| Automatic PET Blow Moulding Machine | Automatic SP - Prestine Machine |

Company Details

Focusing on a customer-centric approach, SHYAM PLASTIC has a pan-India presence and caters to a huge consumer base throughout the country. Buy Injection Moulding Machine in bulk from SHYAM PLASTIC at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

15

Establishment

2000

Related Products

More Product From This seller

Seller Details

Ahmedabad, Gujarat

Proprietor

Mr. Ghanshyam Raijada

Address

Plot No.- 32, Satnam Estate, Near State Bank Of India, Sukharam Nagar, Nagarvel Hanuman Road, Rakhial, Ahmedabad, Gujarat, 380023, India

Injection Moulding Machine in Ahmedabad

Report incorrect details