Automatic Extruded Polystyrene Production Line - Thickness 20-100mm, Width 600-1200mm, High Capacity System | Plc Control, Touch Screen Interface, Customized Density And Color Options

Price:

Get Latest Price

In Stock

Product Specifications

| Computerized | Yes |

| Automatic | Yes |

| Touch Screen | Yes |

| Control System | PLC Control |

| Color | white yellow blue |

| FOB Port | Nanjing |

| Payment Terms | Letter of Credit (L/C), Telegraphic Transfer (T/T) |

| Supply Ability | 500 Per Year |

| Delivery Time | 50 Days |

| Sample Policy | Contact us for information regarding our sample policy |

| Packaging Details | seaworthy packaging |

| Main Export Market(s) | Australia, Eastern Europe, Western Europe, Middle East, Central America, Africa, South America, Asia, North America |

| Main Domestic Market | All India |

| Certifications | CE |

Product Overview

Key Features

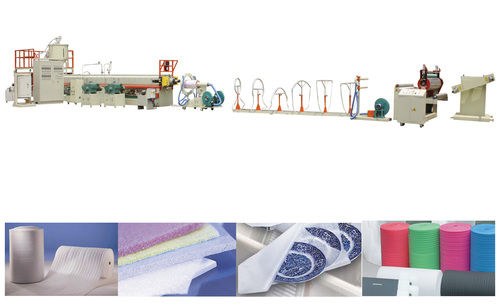

2. Primary Extruder (120 Singer Screw or 150 Singer Screw)

3. Metering System (Special for CO2 Technology or others)

4. Hydraulic screen Exchanger

5. Touch Screen Controller

6. Secondary Extruder (150 Single Screw or 200 Single Screw)

7. Static Mixer

8. Slot Die (Temperature control is necessary)

9. Calibrator

10. First Haul off System

11. Cooling Roller

12. Width Cutting Machine

13. Second Haul Off system

14. Cross Cutting Machine

Optional Equipment

1. Automatic Feeding Machine

2. Surface Grooving Machine

3. Surface Milling Machine

4. Edge Trimming Machine (SL, TG, RC)

5. Milling Machine

6. Embossing Machine

7. Auto stacker

8. Slice Cutting Machine

9. Powder Recycling & Granulating Unit (High Capacity5-6ton/day)

10. Margin Recycle Machine

11. 90C Cutting Machine

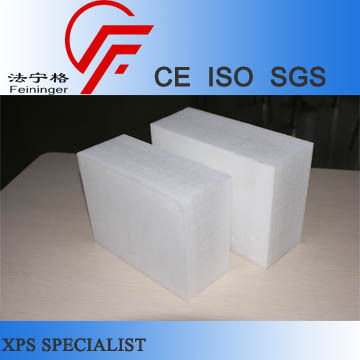

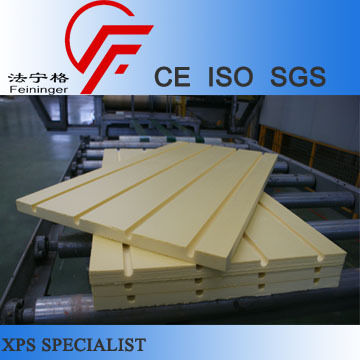

Parameters of Extruded Polystyrene Board:

Thickness: 20-100mm

Width: 600mm/900mm/1200mm

Length: 1200mm/2400mm/3000mm or at your option

Density: 30-50kg/m3

Color: Yellow, Blue, Green Or At Your Option

Company Details

Business Type

Exporter, Manufacturer

Establishment

2002

Working Days

Monday To Friday

Payment Mode

Telegraphic Transfer (T/T)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Nanjing, Jiangsu

Mr Feininger

Address

No. 2, Zhonglin Road, Tangshan Industry Area, Nanjing, Jiangsu, 211132, China

extruded polystyrene in Nanjing

Report incorrect details