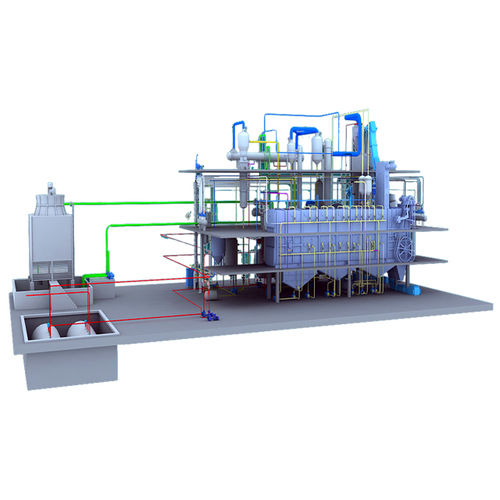

Rice Bran Oil Production Line - 1000-5000t/d Capacity, Automatic Plc Control System, High-efficiency Solvent Extraction, Continuous Refining Process, Energy-saving Design, Advanced Deodorization Technology

Price: 6000 USD ($)

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Computerized | Yes |

| Voltage | 220 Watt (w) |

| Production Capacity | 1000-5000 Ton/day |

| Control System | PLC Control |

| Power | 35 Volt (v) |

| Type | Extractor |

| Material | Rice bran |

| Automatic Grade | Automatic |

| Color | Other |

| Warranty | 5 years |

| Sample Policy | Contact us for information regarding our sample policy |

| Supply Ability | 5000 Tons Per Day |

| Certifications | ISO9001:2008, SGS etc. |

| Main Domestic Market | All India |

| Payment Terms | Cash Advance (CA), Telegraphic Transfer (T/T), Western Union, Cash on Delivery (COD), Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Cash Against Delivery (CAD), Cash in Advance (CID) |

| FOB Port | Qingdao |

| Sample Available | 1 |

| Delivery Time | 30 Days |

| Main Export Market(s) | North America, South America, Africa, Western Europe, Eastern Europe, Australia, Middle East, Asia, Central America |

| GSTIN | 0% |

Product Overview

Key Features

Company Details

Henan Huatai Cereals And Oils Machinery Co.,Ltd. was founded in 1950,whcih is a large-scale oil machinery manufacturing enterprise integrating R & D, design, manufacture and installation as one of the major grain and oil machinery manufacturing enterprises in China.Our company headquartered located in Huaxiang County Industries,Henan Province,China,covering 100,000.00 square meters. Huatai machinery has developed projects including large scale oilseed pretreatment and pressing, oil extraction, oil refining and oil fractionation production line project,conveyor equipment project,corn/maize flour, grits, germ milling machines and corn processing lines,biodiesel technology,cottonseed, rice bran and soybean protein technology, and Palm Oil processing lines,etc. One of the most largest Cooking oils factory in China. Production of grain and oil equipment solutions from A to Z. Huatai is a factory with more than 60 years experience. More than 100,000 square meters. Over 580 professional employees. 8 Large-scale workshop, 120 production equipments. Henan Huatai Cereals And Oils Machinery Co.,Ltd is committed to R&D of new efficient oil machines, manufacturing customer oriented oil machines, and leading the development direction of the world's most advanced grain processing machines and oil processing machines. We are reply on technology and innovation, constantly developing new type oil machines and equipment in order to achieve worlds advanced level.

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company

Employee Count

500

Establishment

1950

Working Days

Monday To Sunday

Certification

ISO9001, SGS

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Zhengzhou, Henan

Ms Ken Wang Wang

Address

B26 No.1, Cuizhu Street High-Tech Zone, Zhengzhou, Henan, 450000, China

rice bran oil equipment in Zhengzhou

Report incorrect details