- Tradeindia

- Shell Mould Castings

- Shell Casting

Shell Casting

(31 products)Shell Reamer Diameter: 13

Price: 11700 INR/Piece

MOQ1 Piece/Pieces

ShapeRound

MaterialHigh Speed Steel

Diameter13, 16, 19, 22, 27, 40, 32 Millimeter (mm)

Processing TypeAssuring you best of series all the time

Shells Investment Casting Application: Pipe Fittings

MOQ100 Unit/Units

MaterialStainless Steel

SurfaceZinc Plated

ApplicationPipe Fittings

Shell Mold Castings - Resin and Sand Materials, Varies in Size | Complex Shapes, Good Surface Finish, High Precision for Steel Castings

MaterialSand, Resin

ProcessShell Molding

ApplicationCylinder Heads

Application2Valve Bodies

Casting TypeMetal Casting

BinderThermosetting

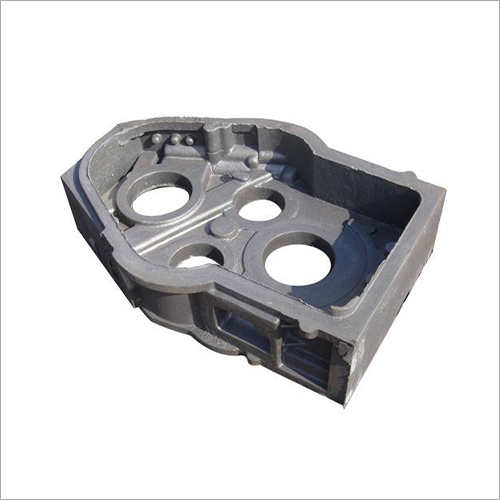

Shell Casting

MaterialCast Iron

WeightUp to 120 KG

DimensionsUp to 600x800x500 mm

StandardsISO, ASTM

GradesFG-150 to FG-400

Surface FinishAs per requirement

View More

Shell Moulding Casting

Get Best Deal

BB Shell Castings

MaterialCast iron

Weight300g-1kg

DimensionsVariable

Surface finishAs cast

Manufacturing processShell casting

Tolerance+/-0.5mm

View More

BB Shell Castings

Get Best Deal

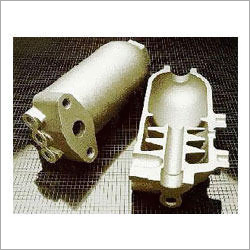

Shell Casting - Aluminum Material, Variable Weight with Smooth Surface Finish | Shell Molding Process, ±0.005 Inches Tolerance for Automotive and Aerospace Applications

MaterialMetal alloy

DimensionsVaried

WeightDependent on size

Surface finishSmooth

ToleranceTight

Production methodShell molding

View More

Shell Moulding Casting

Price Trend : 98.00 - 130.00 INR

Shell Mould Casting - Cast Iron, Various Dimensions | Sand Casting Process, ±0.05mm Tolerance, Ideal for Pump Impellers

Price Trend : 98.00 - 130.00 INR

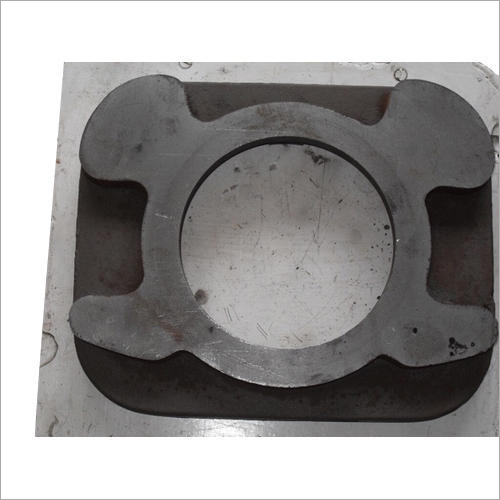

Green Shell Pattern Die

MaterialGreen sand

BinderThermosetting resin

ApplicationSteel castings

UsageAny metal

PartsValve bodies

FeaturesEasy flow, High accuracy, Good finish, Lightweight steel, Any metal

View More

Shell Pattern Mould

Get Best Deal

Instrument Shell Casting

MaterialAluminum Alloy

ProcessDie Casting

Tolerance+/- 0.1mm

SurfaceAs Cast

WeightVaries

DimensionsCustomizable

Shell Molding Dies - Custom Fabricated Solutions | Compliant with Global Standards, Versatile Designs

MaterialSteel Alloy

DimensionsVariable

Surface FinishSmooth

Tolerance+/-0.1mm

UsageShell molding process for metal casting.

WeightVariable

Shell Mold Castings

Product DescriptionWe are offering a superior quality Shell Mold Castings. We use latest machinery and techniques in manufacturing process to offer a flawless range of Shell Mold Castings. After testing on certain parameters, we ensure that these castings are defect free and meet the industry norms & standards of qual

Shell Casting - Durable Metal Alloy | Versatile Application in Food, Chemical, Cement, Automobile, and Mining Industries

Product DescriptionIT IS A SHELL CASTING PRODUCT AND APPLICABLE IN FOOD INDUSTRY, CHEMICAL INDUSTRY, CEMENT INDUSTRY, AUTOMOBILE INDUSTRY AND MINING INDUSTRY

M. K. Industries

Ahmedabad

Deals in:

FAQs Related to Shell Casting

Who are the top shell casting manufacturers in India?

- M. K. Industries

- Endeavour Technologies

- Spago India

Which cities have the largest number of shell casting suppliers?

- Coimbatore

- Ahmedabad

- Rajkot

- Surat

How many trusted sellers are available for shell casting?

- ENDEAVOUR TECHNOLOGIES

- M. K. INDUSTRIES

What is the minimum order quantity for shell casting?

Do listed companies have registration & certifications?

- Harihar Pattern Industry

- M. K. INDUSTRIES

- USHA LINER SHAPAR PVT LTD

- Mahalaxmi Engg. Works

- Benchmark Liners

- SHREE ENTERPRISES

- TRUSHAPE PRECISION CASTINGS PVT. LTD.

What is the get latest price feature?

What types of payment methods are accepted by the shell casting suppliers?

Usha Liner Shapar Pvt Ltd

Rajkot

Deals in:

Mahalaxmi Engg. Works

Kolhapur

Deals in:

Abi Hi Tech Metal Technologies

Coimbatore

Deals in:

View More

Industrial Non Ferrous Shell Casting

Price : 400 INR

Industrial Cast Iron Shell Investment Casting

Price : 370 INR

Malini Cables India Private Limited

Pune

Deals in:

Benchmark Liners

Ahmedabad

Deals in:

Global Castings

Baddi

Deals in:

M/s Shakti Engineering Works

Agra

Deals in:

Modern Technocast

Ahmedabad

Deals in:

Casting India

Coimbatore

Deals in:

Shree Enterprises

Belgaum

Deals in:

Djit Solutions

Howrah

Deals in:

Trushape Precision Castings Pvt. Ltd.

Bhavnagar

Deals in:

Leo Shellcasts Industries

Coimbatore

Deals in:

View More

Aluminum Shell Mould Castings

Get Best Deal

Shell Mould Ductile Iron Castings

Get Best Deal

Shell Mould Iron Castings

Get Best Deal

Permanent Shell Mould Castings

Get Best Deal

Ceramic Shell Casting

Get Best Deal

Shell Mould Castings

Get Best Deal

More details...

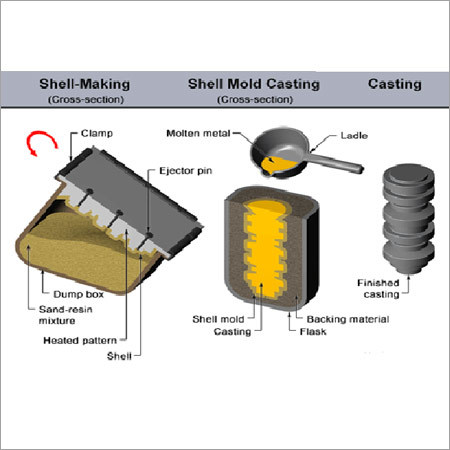

Shell casting is a mold casting process distinguished by the use of resin covered sand for forming the mold. This process is ideal for producing small to medium sized components with optimum precision. This casting process allows the usage of both ferrous as well as non ferrous metals and is most commonly done using cast iron, carbon steel, alloy steel, copper alloys, stainless steel etc. Typical parts that are manufactured in various industries using this process include cylinder heads, gears, bushings, connecting rods and many more.

Shell casting process offers many advantages such as it can be completely automated for mass production, very good surface finish of the produced metal components, generation of minimal scrap during the process etc. After having been invented in the mid 20th century, this process gradually became popular amongst manufacturers and today it's one of the most favored metal forming techniques.

The Shell Casting Process Has the Following Steps

Fine grained sand is mixed with a thermosetting resin binder.

A special metal pattern is coated with a parting agent that will later facilitate in the removal of the shell.

The metal pattern is then heated to a temperature ranging between 350 F- 700F.

Afterwards, the sand mixture is poured over the hot casting pattern.

As a result of the reaction of thermosetting resin with the hot metal pattern, a thin shell is formed on the pattern's surface.

After removal of the excess sand, the shell and pattern are both placed in an oven for some minutes, causing the shell to harden on to the casting pattern.

The hardened shell is then separated from the casting pattern.

The manufacture of the shell mold is complete and is now ready for metal casting.

Features of Shell Casting

The thickness and weight of mold is lesser in this process as compared to other casting processes.

This process is perfect for making circular and symmetrical components.

Lower draft angles can be used in shell casting.

The metal components produced are resistant to weakening and deformation.

Shell casting can also be used to produce products with very thin wall thickness.

Shell Casting vs Sand Casting

Shell casting process has many advantages over sand casting process. Some of these advantages are,

This process produces components that have a comparatively better dimensional accuracy.

Also, this process enables a much higher productivity rate than sand casting.

Lower labor requirements.

Through this process, components with complex shapes can easily be formed.

Minimal tooling and equipment costs.

Shell Casting Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

M. K. Industries Ahmedabad, India | 17 Years |

Endeavour Technologies Pune, India | 11 Years |

Spago India Delhi, India | 3 Years |

Upcoming Tradeshows

CWIEME Shanghai 2026

Wed, 24 Jun, 2026 - Fri, 26 Jun, 2026

INDOMACH Jamshedpur 2026

Thu, 05 Feb, 2026 - Sun, 08 Feb, 2026

Asia Photonics Expo (APE 2026)

Wed, 04 Feb, 2026 - Fri, 06 Feb, 2026

IFF - India Fashion Forum 2026

Wed, 28 Jan, 2026 - Thu, 29 Jan, 2026

Plastic Packaging Printing Expo (P3) 2026

Fri, 10 Apr, 2026 - Mon, 13 Apr, 2026

STEEL CONSTRUCTION EXPO 2026

Thu, 26 Feb, 2026 - Sat, 28 Feb, 2026

Panacea - Natural Products Expo India 2026

Fri, 06 Mar, 2026 - Sun, 08 Mar, 2026

India Boat & Marine Show 2026

Thu, 29 Jan, 2026 - Sat, 31 Jan, 2026

Spectra Expo 2026

Wed, 06 May, 2026 - Fri, 08 May, 2026

Odisha Mining & Infrastructure International Expo 2026

Thu, 08 Jan, 2026 - Sun, 11 Jan, 2026

Popular Categories