- Tradeindia

- Cutting Machine

- Pipe Cutting Machine

Pipe Cutting Machine

(457 products)Automatic Pipe Cutting Machine Capacity: 125 Milliliter (Ml)

Price: 5 INR/Piece

MOQ1 Piece/Pieces

Product TypePipe Cutting

MaterialIron Casting

ComputerizedNo

Automatic GradeAutomatic

Control SystemPLC Control

Drive TypeHydraulic

Gamut Machine Tools

Dombivli

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller15 Years

View More

GAMUT Semi-Automatic Hydraulic Pipe Cutting Machine

Get Best Deal

GAMUT Automatic CNC Pipe Cutting Machines

Get Best Deal

GAMUT Semi-Automatic Mild Steel Pipe Cutting Machine - 750x950x1600mm, Blue Color, Vibration-Free Cutting, Burr Free, Mitre Cutting, Precision Cooling System

Price : 224800 INR

Semi-Automatic Gamut 315 Model Pipe Cutting Machine

Price : 225000.00 INR

Semi Automatic Hydraulic Pipe Cutting Machine In Thane Gamut Machine Tools, Weight (kg): 750 Kg

Get Best Deal

Gamut Automatic Pipe Cutting Machine Capacity: 130Mm Milliliter (Ml)

Price : 1420000.00 INR

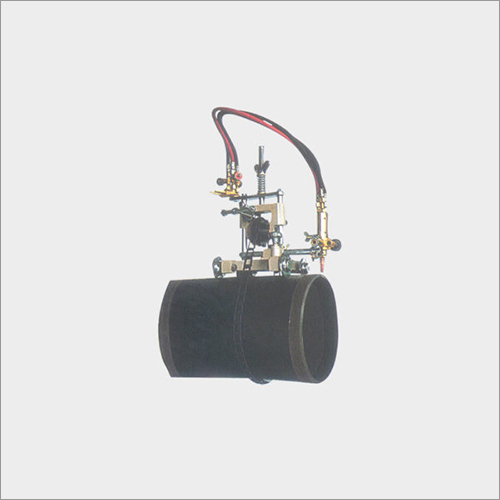

Gas Pipe Cutting Machines Dimension(L*W*H): 350X310X180 Millimeter (Mm)

Price: 700 INR/, Piece

MOQ200 , Piece/Pieces

Weight400-2000 Kilograms (kg)

Length1.500 Millimeter (mm)

ColorBlack

MaterialStainless Steel

Handle MaterialAluminum

ShapeRectangle

View More

MANUAL GAS PIPE CUTTING MACHINE

Price : 315000.00 INR

ELECTRO GAS PIPE CUTTING MACHINE

Price : 315000.00 INR

Hinged Pipe Cutters Handle Material: Aluminum

Price : 700 INR

Simple Control Die Head 145D

Price : 53000.00 INR

Pipe Threading Machine 1101C - Color: White

Price : 1166000.00 INR

Pipe Threading Carriage Stand - Color: Orange

Price : 37100.00 INR

Cutogen 5 Cutting Blowpipe - Color: Golden

Price: 1000 INR/Unit

MOQ1 Unit/Units

ColorGolden

UsageIndustrial

TypeCUTTING BLOWPIPE

MaterialBrass

Product TypeCUTOGEN 5 CUTTING BLOWPIPE

High Pressure Water Jet Cutting and Beveling Machine

Price Trend: 20000.00 - 50000.00 USD ($)/Set

MOQ1 Set/Sets

Drive MotorAC Servo Motor

Product TypeAutomatic Water Jet Cutting Equipment

General UsePrecise Industrial Cutting & Beveling

MaterialOther, Stainless Steel / Mild Steel / Glass / Ceramic / Stone / Composite

TypeOther, High Pressure Water Jet Cutting and Beveling Machine

CapacityIndustrial Grade Continuous Operation

Shanghai Qianshan Piping Technology Co., Ltd.

Shanghai

Trusted Seller

Trusted Seller Super Seller

Super Seller12 Years

View More

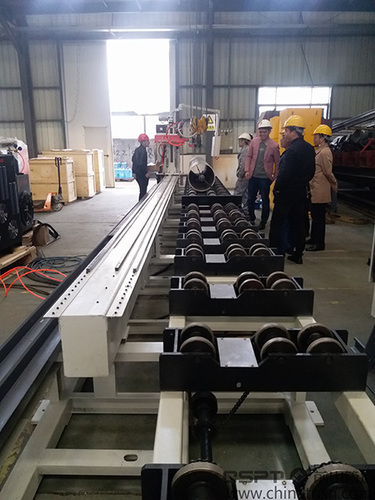

Pipe Beveling Machine - Low Carbon Steel, Cutting Torch Quantity: 1 Piece, Red and Gray | CNC Technology, Automatic Operation, Lightweight, High Efficiency, 1-Year Warranty

Price Trend : 30000.00 - 60000.00 USD ($)

Pipe Cutting Beveling Machine

Price Trend : 30000.00 - 60000.00 USD ($)

Roller Bench Type Pipe Flame Beveling and Cutting Machine

Price Trend : 20000.00 - 50000.00 USD ($)

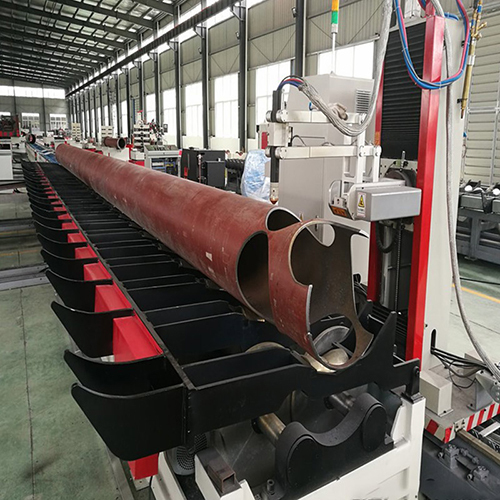

CNC Pipe Cutting Machine - Automatic Operation, Precision Cutting for Metal Fabrication and Pipeline Industries | Advanced CAD/CAM Integration, Multi-Axis Control, Safety Features

Price Trend : 4999.00 - 9999.00 USD ($)

Pipe Fabrication Fast Fitting Up Machines

Get Best Deal

High Speed Pipe Band Saw Cutting Machine

Get Best Deal

Automatic Computer Bellow Pipe Cutting Machines

ApplicationBellow pipe cutting

ConditionAutomatic, Other

Manufacturing Year2023

Production SpeedAdjustable

PowerElectric

FunctionPrecise cutting of bellow pipes

Pipe Cutting Bevelig Machine (Self Centre) - Color: Multicolor

Price: 350000 INR/Piece

MOQ2 Piece/Pieces

ColorMulticolor

Power SourceElectricity

Operating TypeAutomatic

Power120 Watt (w)

Surface TreatmentGalvanized

WarrantyYes

Shingare Industries Private Limited

Mumbai

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller13 Years

View More

Pipe Cutting Bevelig Machine (Auto Centre) - Color: Multicolor

Price : 300000 INR

Pipe Cutting And Beveling Machine - Color: Multicolor

Price : 980000 INR

Cam Type Pipe Cutting And Beveling Machine - Color: Multicolor

Price : 280000 INR

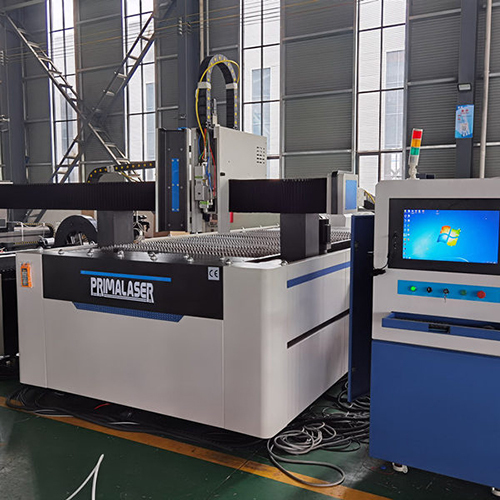

High Efficiency Customized Pipe Punching And Cutting Machine

MOQ1 Unit/Units

Product TypeCustomized Pipe Punching And Cutting Machine

General UseIndustrial

AutomaticYes

Drive TypeElectric

FeatureHigh Efficiency

Nanjing Prima Cnc Machinery Co., Ltd.

Nanjing

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller4 Years

View More

2 In1 Sheet And Pipe Fiber Laser Cutting Machine

Get Best Deal

Sheet And Pipe Fiber Laser Cutting Machine

Get Best Deal

Plastic Pipe Cutting Unit - Steel, 1500x1000x1200mm, Blue | Cutting Capacity: 50-200mm, Motor Power: 3-5kW, Weight: 500-1000kg, Emergency Stop

Product TypePipe Cutter

Dominant ColorBlue

Cutting Capacity50-200mm

Motor Power3-5kW

MaterialSteel

Dimensions1500x1000x1200mm

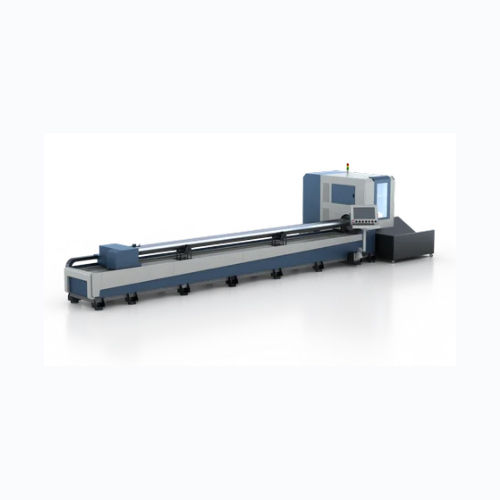

Automatic Pipe Laser Cutting Machine By Jayita Cad Cam Systems

Price: 4500000 INR/Piece

MOQ1 Piece/Pieces

ColorBlue

Product TypePipe Laser Cutting Machine

Automatic GradeAutomatic

Cooling ModeWater Cooling

Control SystemPLC Control

Voltage220 Volt (v)

Jayita Cad Cam Systems

Kolkata

Trusted Seller

Trusted Seller Super Seller

Super Seller3 Years

Pipe Cutting Machine - High Speed Steel, Standard Size, Blue | Burr Free Operation, Low Noise Environment, Fast Precision Cutting with Mitre Angles

Price: 120000.00 INR/Set

MOQ1 Set/Sets

Operate MethodSemi-Automatic

Cutter TypeCircular Cutter

FeaturesFast operation; Durable; Easy-to-use control panel

Coating TypeIndustrial-grade

UsageIndustrial

Cutting AccuracyHigh Precision

Timus Tooling System Private Limited

New Delhi

Trusted Seller

Trusted Seller Super Seller

Super Seller10 Years

View More

Timus Pipe Cutting Machine

Get Best Deal

Fully Automatic Pipe Cutting Circular Saw Machine

Saw blade dia12"-18"

Max cut depth4"-6"

Blade speed3200 RPM

Table size21"x30"-27"x36"

Power2-5 HP

MaterialSteel

Pipe Cutting Bandsaw Machine - Color: Blue

Price: 1550000.0 INR/Unit

MOQ1 Unit/Units

ColorBlue

Product TypePipe Cutting Bandsaw Machine

General UseIndustrial

ComputerizedNo

AutomaticYes

Control SystemPLC Control

FAQs Related to Pipe Cutting Machine

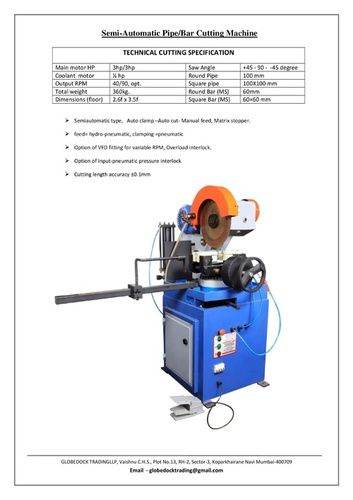

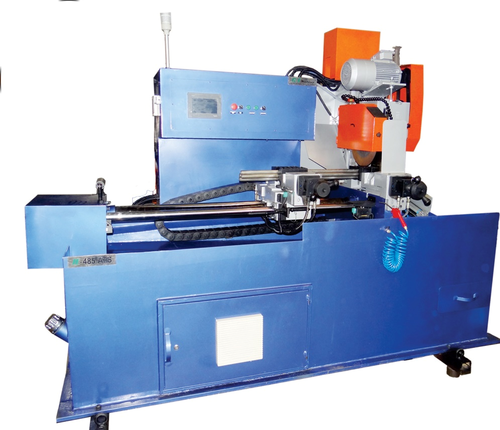

Je 485 At S Automatic Servo Pipe Bar Cutting Machine (2 Axis) - Blade Size: 400

Price: 1450000 INR/Unit

MOQ1 , Number

ColorBlue

Product TypePipe Bar Cutting Machine

General UseCutting

Weight (kg)2 Tonne

ComputerizedNo

AutomaticYes

View More

Je 350 Semi Automatic Pipe Bar Cutting Machine - Color: Blue

Price : 280000 INR

Blue Je 315 Semi Automatic Pipe Bar Cutting Machine

Get Best Deal

Automatic World Class Metal Tube Working Machines

Get Best Deal

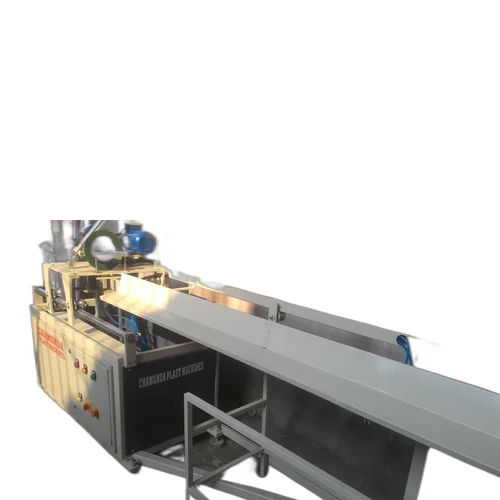

Automatic Conduit Pipe Machine - Capacity: 15-50 Kg/Hr

Price: 2100000 INR/Unit

MOQ1 Unit/Units

ColorSilver

General UseIndustrial

MaterialSteel

TypeAutomatic Cutting Machine

Capacity15-50 Kg/hr

ComputerizedNo

Jimkhaas Extrusions

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

View More

Blue Pvc / Hdpe Pipe Cutting Machine

Price : 150000 INR

Hdpe Pipe Cutting Machine - Capacity: 100 Kg/Hr

Price : 150000 INR

Metal Sheet And Pipe Laser Cutting Machine

Laser TypeCO2

Max Sheet Thickness6mm

Cutting SpeedVariable

Control SystemHSG software

AccuracyHigh precision

UsageMetal sheet and pipe cutting

Laser Technologies Pvt. Ltd.

Navi Mumbai

Trusted Seller

Trusted Seller Premium Seller

Premium Seller14 Years

Boiler Header Pipe Cutting Machine - Color: Silver

Price: 100000.0 INR/Unit

MOQ1 Unit/Units

ColorSilver

MaterialSteel

TypeAutomatic Cutting Machine

AutomaticYes

Cutting FunctionSemi Automatic

Voltage220-440 Volt (v)

Fabmax Pipe Fabrication Machines Pvt. Ltd

Mumbai

Trusted Seller

Trusted Seller1 Years

View More

Pneumatic Pipe Cutting And Beveling Machine - Color: Silver

Price : 300000 INR

In-Situ Pipe Cutting & Beveling Machines - Color: Gray

Price : 300000 INR

Semi-Automatic Pipe Cutting Machine - Color: Silver

Get Best Deal

Hydraulic Pipe Cold Cutting And Beveling Machine - Steel Material, 220-440 Volt Operation, Silver Color | Automatic Functionality, Durable Design

Price : 100000 INR

Portable In-Situ Pipe Cutting Machines - Color: Gray

Price : 100000 INR

Polish Computer Controlled Pipecutter

Capacity24ft

Diameter1"-12.750"

Roller bedYes

Plasma torchYes

Cut typesMultiple

ControlComputer

View More

Ear Plugs - Polyurethane Foam, 33 NRR Noise Reduction, Comfortable Orange Color, Superior Hygiene & Better Attenuation

Get Best Deal

Eye Protection Goggles - Shade #11 Polycarbonate Lens & Soft PVC Frame, Fog-Reducing Air Circulation Valves

Get Best Deal

4 Axis Cnc Pipe Profile Cutting Machine

Get Best Deal

Semi Automatic Plasma Cutting Machine

Get Best Deal

Round Pipe Cutting Machine - Automatic Grade: Automatic

Price: 480000 INR/Piece

MOQ1 Piece/Pieces

ColorOther, Grey

Usage & ApplicationsIndustrial

PhaseThree Phase

Product TypeRound Pipe Cutting Machine

MaterialMetal

Cutting Thickness15 Millimeter (mm)

A One Machinery Equipment

Faridabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller4 Years

Gi Pipe Cutting Blade - Blade Size: 10 Inch To 14 Inch

Price: 2800 INR/Piece

MOQ50 Piece/Pieces

BladeÃÂ Size10 Inch To 14 Inch

ShapeCircular

UsageIndustrial

Product TypeGi Pipe Cutting Blade

Neh8C Pipe Cutting Machine - Country Of Origin: India

MOQ1 Piece/Pieces

Voltage220 Volt (v)

Country Of OriginIndia

Control SystemSemi-Automatic

Product TypeOther, Pipe Cutting Machine

Power SourceElectricity

Operating TypeSemi Automatic

Nandini Entrepreneur Equipments Pvt. Ltd.

Faridabad

Trusted Seller

Trusted Seller7 Years

View More

Electric Pipe Cutting Machine - 2 To 8 - Color: Grey

Get Best Deal

NEH12C Pipe Cutting Machine

Get Best Deal

Pipe Cutting Machine - Color: Yellow

MOQ5 Piece/Pieces

Product TypeOther, Pipe Cutting Machine

Power SourceElectricity

Operating TypeSemi Automatic

Surface TreatmentCoated

ColorYellow

Warranty1 Year

Pipe Cutting Machine - Robust Design, 1452x1044x1046mm , Model MPC002, Air Pressure 0.4-0.6 MPa, Capacity 10pcs/min, Power 1.1kW, Weight 503kg

Price: 20000 USD ($)/Set

MOQ1 Set/Sets

Drive MotorElectric

Product TypeIndustrial Machine

General UseFor cutting MS, SS, GI pipes

MaterialOther, Mild steel

TypeOther, Pipe Cutting Machine

Capacity300 pipes per day

Suzhou Boarding Industrial Co. Ltd.

Suzhou

Trusted Seller

Trusted Seller Premium Seller

Premium Seller10 Years

Metal Pipe Cutting Machine - Blade Size: 500 Mm

Price: 1245000.00 INR/Unit

MOQ1 Unit/Units

General UseIndustrial

MaterialOther, Stainless Steel

ComputerizedNo

AutomaticYes

BladeÃÂ Size500 mm

Drive TypeElectric

Accurate Cutting Systems Private Limited

Pune

Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

400Mm Pipe Cutting Machine - Feature: Good Quality

Price: 450000 INR/Unit

MOQ1 Unit/Units

Product TypePipe Cutting Machine

General UseIndustrial

MaterialSteel

ComputerizedNo

AutomaticYes

Drive TypeElectric

View More

Automatic Pipe Cutting Machine - Feature: Good Quality

Price : 450000.0 INR

Good Quality Industrial Silicon Pipe Cutting Machine

MOQ1 Unit/Units

Product TypePipe Cutting Machine

General UseIndustrial

MaterialMetal, Other

AutomaticYes

Drive TypeElectric

FeatureGood Quality

Industrial Pipe Cutting Machine - Capacity: 40-100 Kg/Hr

Price: 675000 INR/Unit

MOQ1 Unit/Units

General UseIndustrial

MaterialOther, Mild Steel

Capacity40-100 Kg/hr

AutomaticYes

Control SystemPLC Control

Drive TypeElectric

Black & Blue Pipe Cutting Machine

Price Trend: 50000.00 - 100000.00 INR/Piece

MOQ1 , Piece/Pieces

Voltage110-220 Volt (v)

Product TypePipe Cutting Machine, Other

Frequency (MHz)50 Hertz (HZ)

Starting TypeElectric Start

ColorBlack & Blue

Warranty1 Year

20 HP CNC Pipe Cutting Machine - High-Quality Steel | Automatic, Low Energy Consumption, PLC Control, High Efficiency

Price: 3300000 INR/Unit

MOQ1 Unit/Units

General UseIndustrial

MaterialSteel

AutomaticYes

Drive TypeElectric

Voltage20 Horsepower (HP)

FeatureHigh Efficiency, Low Energy Consumption

View More

Cnc Fiber Laser Pipe Cutting Machine - Cutting Area: 3000*1500 Square Millimeter (Mm2)

Price : 3500000.0 INR

240V Cnc Rotary Pipe Cutting Machine - Feature: Good Quality

Price : 4500000 INR

Cnc Pipe Laser Metal Cutting Machine - Cutting Area: 3000*1500 Square Millimeter (Mm2)

Price : 3900000 INR

Cnc Sheet And Pipe Cutting Machine - Color: Red

Price : 3500000.0 INR

Cnc Sheet And Pipe Cutting Machine - Feature: Good Quality

Price : 3500000.0 INR

Cnc Tube And Pipe Laser Cutting Machine - Automatic Grade: Automatic

Price : 3000000 INR

Popular Pipe Cutting Machine

What is Pipe Cutting Machine?

Uses & Benefits of Pipe Cutting Machine

Types of Pipe Cutting Machine

Things to Consider Before Buying a Pipe-Cutting Machine

Client Testimonials & Reviews

It is a great honor to write this recommendation letter for the international marketing department of tradeindia.com. Our company mainly produces transformer equipment, including: Unicreo machine ,Transformer core cutting machine, silicon steel slitting machine ,Foil winding machine , our first order is also in Started by the founder, through the promotion of the platform, it has played a good role in our international trade, opened up many customers, and has different consulting customers every day, and opened up the markets of India, Pakistan and Bangladesh. Thanks to tradeindia.

JagdishPatel

SHREE KHODIYAR ELECTRICALS

We are much satisfied with the service and response from tradeindia. We are having many client through online marketing. We wishes best future for tradeindia.

RajeshPrajapati

R. K. HYDRAULICS

We are happy to be registered member of tradeindia.com since 2014. We are very much satisfied by the services and inquiries provided by the tradeindia. We recommend tradeindia, it's the best B2B platform for branding and promotion of companies.

We have been a paid member of tradeindia for past 5 years. Our products got promoted at tradeindia portal as well as Google promotion. We received relevant business inquiries from potential clients. We are looking for a long term relationship with tradeindia, and hope tradeindia provides best services in future also.

Vipulsanghvi

JANAK ENTERPRISES

We are associated with tradeindia since last 5 years. Tradeindia has helped in our Marketing Campaign in multiple ways. Currently bulk of our Promotion and Sales materialise with the help of tradeindia. Thanking you tradeindia.com for continuous support and partnership.

KashyapRay

GGR ENTERPRISES

We are very glad with tradeindia and their services. They are the Best B2B portal in their domain. May you grow and prosper.

Pipe Cutting Machine Price List

This Data was Last Updated on 2025-12-27

Pipe Cutting Machine Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Intimate Machine Tools Rajkot, India | 22 Years |

Gamut Machine Tools Dombivli, India | 15 Years |

Janak Enterprises Bhavnagar, India | 15 Years |

Nilkanth Engitech Private Limited Rajkot, India | 14 Years |

Laser Technologies Pvt. Ltd. Navi Mumbai, India | 14 Years |

Mehta Sanghvi & Co. Mumbai, India | 14 Years |

Shingare Industries Private Limited Mumbai, India | 13 Years |

Multicut Machine Tools Vadodara, India | 13 Years |

Inder Industries Jalandhar, India | 12 Years |

Shanghai Qianshan Piping Technology Co., Ltd. Shanghai, China | 12 Years |

Upcoming Tradeshows

CWIEME Shanghai 2026

Wed, 24 Jun, 2026 - Fri, 26 Jun, 2026

INDOMACH Jamshedpur 2026

Thu, 05 Feb, 2026 - Sun, 08 Feb, 2026

Asia Photonics Expo (APE 2026)

Wed, 04 Feb, 2026 - Fri, 06 Feb, 2026

IFF - India Fashion Forum 2026

Wed, 28 Jan, 2026 - Thu, 29 Jan, 2026

Plastic Packaging Printing Expo (P3) 2026

Fri, 10 Apr, 2026 - Mon, 13 Apr, 2026

STEEL CONSTRUCTION EXPO 2026

Thu, 26 Feb, 2026 - Sat, 28 Feb, 2026

Water Expo Guwahati 2026

Thu, 12 Mar, 2026 - Sat, 14 Mar, 2026

India Boat & Marine Show 2026

Thu, 29 Jan, 2026 - Sat, 31 Jan, 2026

Spectra Expo 2026

Wed, 06 May, 2026 - Fri, 08 May, 2026

Odisha Mining & Infrastructure International Expo 2026

Thu, 08 Jan, 2026 - Sun, 11 Jan, 2026

Popular Categories