Dosing Chemical Triple Row System

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel |

| Dimensions | Variable |

| Power | Hydraulic |

| Capacity | 1500Mm |

| Speed | 9 Circles/Min |

| Rows | Triple |

| Type | Rotary Shear |

| Features | High Productivity, Cost Savings, Material Saving, Simple Operation, Low Power Use, Versatile Material, Large Diameter, Efficient Blanking |

Product Overview

Key Features

Triple Row System

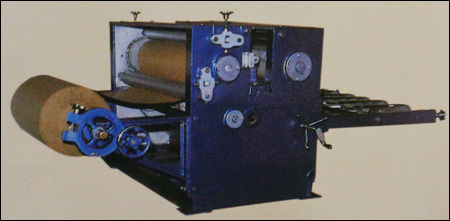

REDSON has designed and developed the On Line Rotary Shearing System to directly Blank circles continuously from a coil, thus eliminating the requirement of Guillotine Shears, Mechanical Hydraulic Presses, Blanking Tooling etc.

The System

On Line Rotary Shearing System Consists of the following:

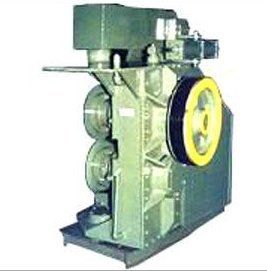

- Hydraulic Decoiler.

- Hydraulic Straightener.

- On Line Rotary Shears.

- Idler Conveyors & Power Conveyor.

- Hydraulic Cut Off Shear.

The Principle

The Principle of Shearing Circles is by On Line Rotary Shearing Method - that is, while the sheet is held rigidly, a pair of cutters rotates around the cutting tool and produces a perfect circle.

Online Rotary Shearing can be done in a single row, double row or in triple row where 2 / 3 Nos. of On Line Rotary Shears are placed diagonally opposite to perform Jig-jag Blanking.

Hydraulic Decoiler and Hydraulic Straightner are provided to decoil and straighten the decoiled sheet. After circle blanking by the On Line Rotary Shear, Hydraulic Cut Off Shear cuts off the scrap.

The Advantages

Blanking of Circles out of Mild Steel, Stainless Steel, Aluminum & other non-ferrous materials, from coils -eliminating the need to make squares and hence the elimination of Guillotine Shear, Presses and Blanking Tooling.

Blanking of large Dia Circles up to 1500mm, which otherwise is very difficult to produce from presses, which should be of high capacity & huge Blanking Tooling.

Blanking of Circles in 2 /3 rows in Jig-jag position, thereby effecting a saving of 7-10% on material.

Substantial Reduction in manpower-by eliminating operations like shearing, Press Blanking & Intermediate Material movements.

Simplicity in operation & maintenance compared to huge press & press tool maintenance.

Low Power Consumption because of revolutionary Rotary Shearing Principle, when compared to high power consuming shears & presses.

Cost saving of 7-10% on material & other by saving on labour, Power, material handling, material price etc.

High Productivity up to 9 circles per minute.

Company Details

Focusing on a customer-centric approach, Redson Engineers Ltd. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Shearing Machine in bulk from Redson Engineers Ltd. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

100

Establishment

1983

Working Days

Monday To Sunday

GST NO

36AAACR9569E1Z2

Certification

ISO 9001

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 36AAACR9569E1Z2

Hyderabad, Telangana

Director

Mr. P. S. Rao

Address

F-9/B, Phase-1, IDA Jeedimetla, Hyderabad, Telangana, 500055, India

rotary shearing machines in Hyderabad

Report incorrect details