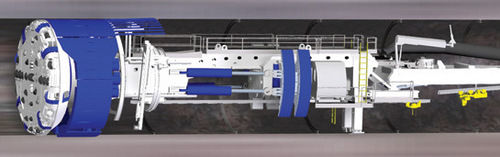

Tunnel Boring Machine - 3 To 15 Meter Diameter | Advanced Floating Gripper System, Hydraulic Propel Cylinders, Continuous Steering, Optimal Cutter Head Design

Price:

Get Latest Price

In Stock

Product Specifications

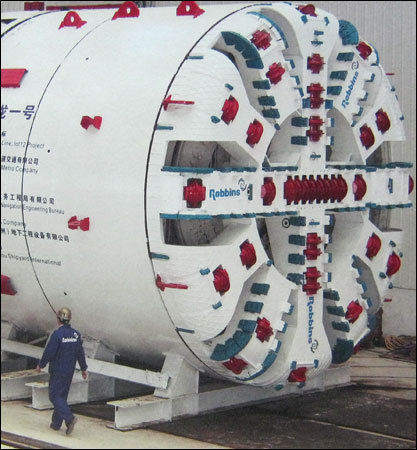

| Diameter | 3-15 Meters |

| Cutters | 11-20 Inch |

| Material | Steel, Carbide |

| Drive | Hydraulic |

| Conveyor | Belt |

| Gripper | Floating |

| Control | Computerized |

| Features | Efficient Excavation, Precise Steering, Safe Operation, Quick Access, Durable Design, Versatile Sizes, High Thrust, Easy Maintenance |

Product Overview

Key Features

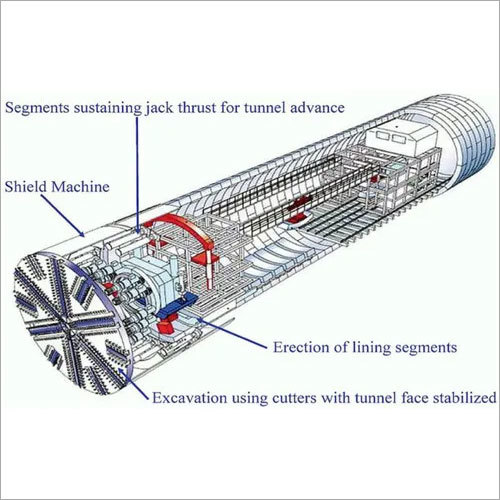

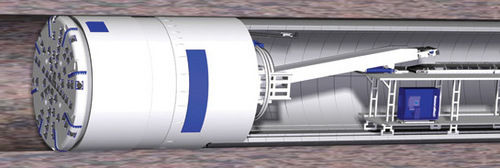

As the cutter head turns, hydraulic propel cylinders push the cutters into the rock. The transfer of this high thrust through the rolling disc cutters creates fractures in the rock causing chips to break away from the tunnel face.

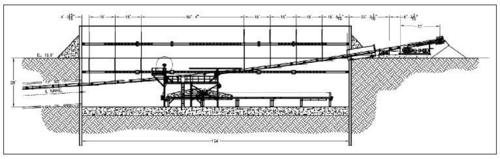

A unique floating gripper system pushes on the sidewalls and is locked in place while the propel cylinders extend, allowing the main beam to advance the TBM .

The machine can be continuously steered while gripper shoes push on the sidewalls to react the machinea s forward thrust.

Buckets in the rotating cutter head scoop up and deposit the muck on to a belt conveyor inside the main beam.

At the end of a stroke the rear legs of the machine are lowered, the grippers and propel cylinders are retracted.

Main Beam TBMa s open design allows quick access directly behind the cutterhead for the installation of rock support (rock bolts, steel mesh, ring beams, and shotcrete), making it an ideal solution for unlined tunnels.

Main Beam TBMs are manufactured in diameters from 3 to 15 mtr.

Company Details

Focusing on a customer-centric approach, ROBBINS TUNNELING & TRENCHLESS TECH (I) PVT. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Get Mining, Exploration & Drilling Machinery from ROBBINS TUNNELING & TRENCHLESS TECH (I) PVT. LTD. at Trade India quality-assured services.

Business Type

Exporter, Manufacturer, Service Provider, Supplier

Establishment

2005

Related Products

Explore Related Categories

More Product From This seller

Seller Details

New Delhi, Delhi

Purchase Manager

Mr. Rohit Kumar

Address

Suite no-8, 3rd Floor, Yashwant Place, Chanakyapuri, New Delhi, Delhi, 110021, India

tunnel boring machines in New Delhi

Report incorrect details