- Tradeindia

- Abrasives

- Grinding Wheels

Grinding Wheels

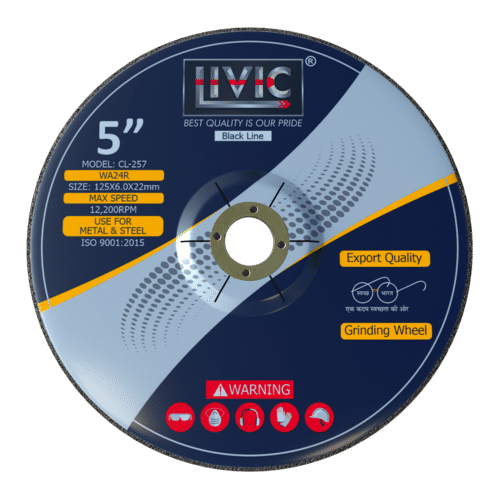

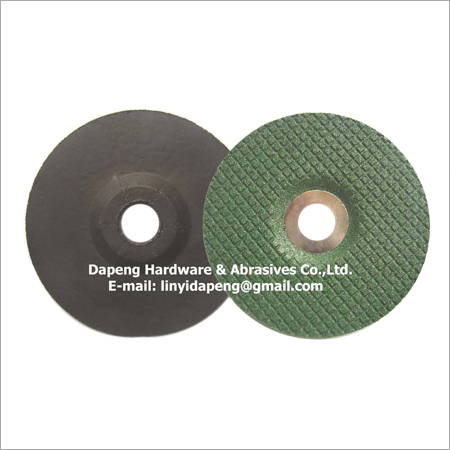

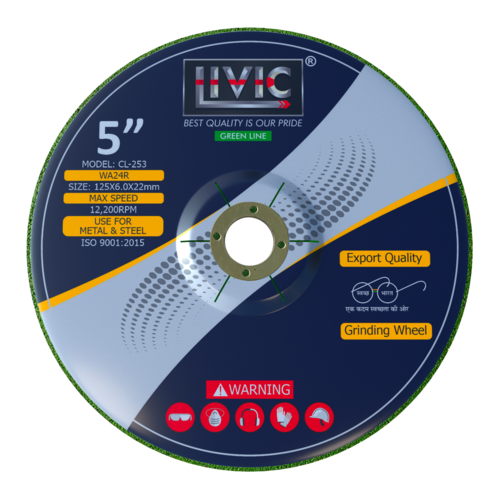

(2297 products)5 Inch Grinding Wheel Black Color Cutting Speed: 12200 Rpm

Price Trend: 30-60 INR/Piece

MOQ1000 Piece/Pieces

UsageMetal & SS Grinding

Cutting Speed12200 RPM

Size5"

Product TypeGrinding wheel

ColorBlack

Credence Livic Industries Llp

Ahmedabad

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller5 Years

View More

5 Inch Grinding Wheel 6Mm Cutting Speed: 12200 Rpm

Price : 30-60 INR

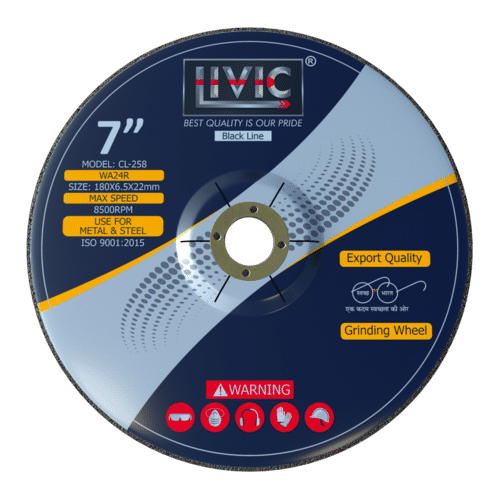

7X6 Gold Line Black Color Grinding Wheel Cutting Accuracy: 100 %

Price : 65-100 INR

7 Inch Grinding Wheel 6 Mm Cutting Speed: 8600 Rpm

Price : 60-100 INR

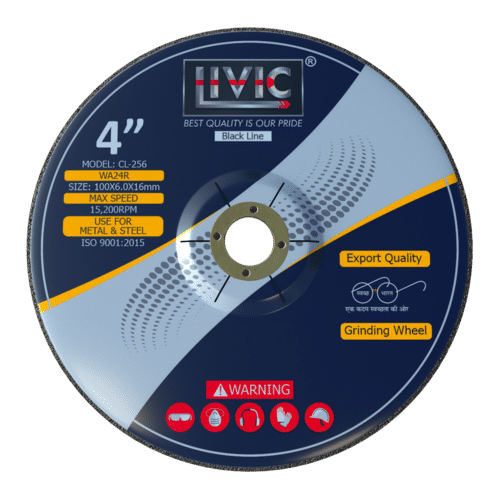

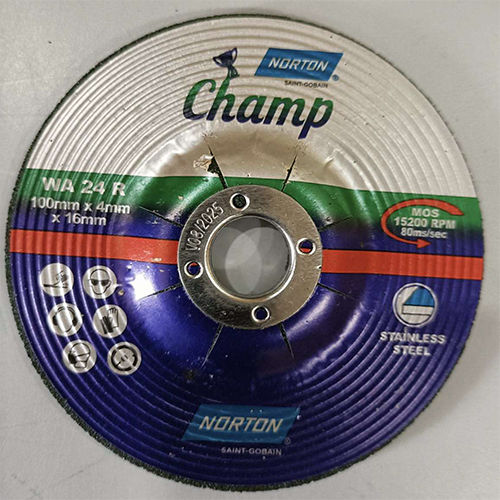

Black Hard Alloy Grinding Wheel - 4 Inch Size (100x4x16 mm) | 100% Cutting Accuracy, 15200 RPM Speed

Price : 16-25 INR

Black Grinding Wheel 6Mm

Price : 10-30 INR

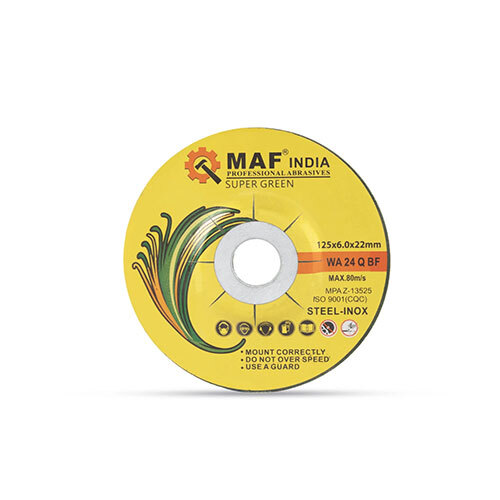

Grinding Wheel - Color: Yellow

MOQ500 Piece/Pieces

SizeStandard

MaterialHigh-Speed Steel (HSS) Tungsten carbide tips

ApplicationWoodworking Metalworking

Power SourceManual

ColorYellow

FeaturesLightweight, Flexible, Easy to Install

National Trading Company

Bhiwandi

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller10 Years

Eco Friendly Hand Grinding Wheels - Coarse/Medium Aluminium Oxide & Silicon Carbide, Brown, Resin Bonded | Manual Control, CNC, For Weld Grinding & Spot Cleaning

Price: 14 INR/Piece

ShapeRound

Chemical CompositionNA

HardnessNA

ToughnessNA

BackingNA

Grain TypeNA

View More

Glass Emery Wheel - 100x16 mm, Brown Color | Ideal for Abrading, Grinding, Polishing Glass, Beveling, and Dhar Polishing

Price Trend : 37.00 - 60.00 INR

Resinoid Bonded Grinding Wheels

Get Best Deal

Abrasive Grinding Wheels - Premium Aluminum Oxide | High Durability, Efficient Material Removal, Versatile Applications

Price : 12 INR

Hand Stone Grinding Wheel - Silicon Carbide | 100mm Diameter, 25mm Thickness, Grade C.60 C.60/120, Brown Round Blade

Get Best Deal

Industrial Grinding Wheels - Color: Black

Price : 2500.0 INR

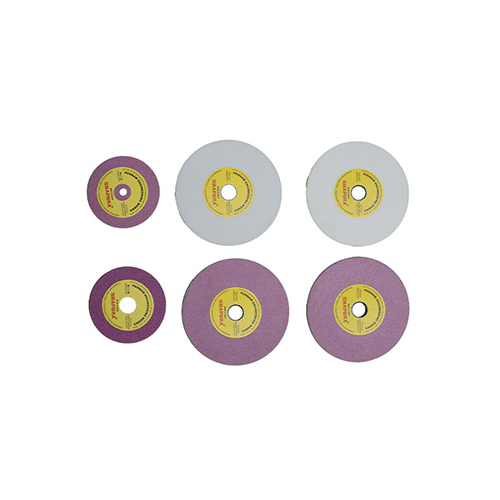

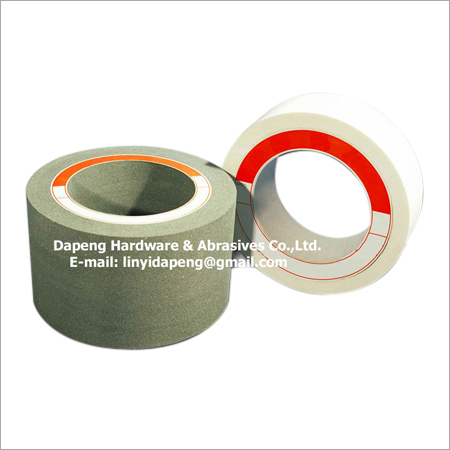

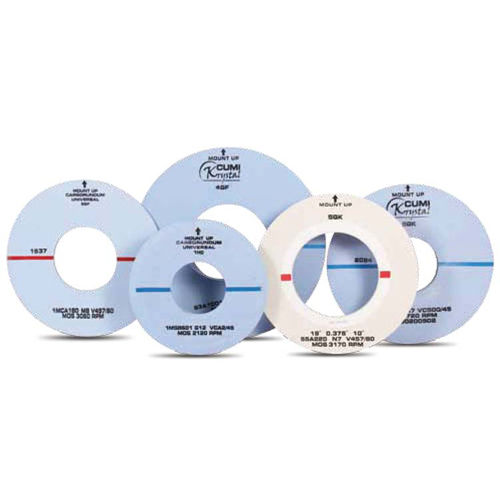

Aluminium Oxide Cylindrical Grinding Wheel

Price: 700 INR/Piece

MOQ100 Piece/Pieces

ColorGrey

UsageGrinding Use

MaterialAlumina

ShapeCircular

SizeMultiple

Product TypeAluminium Oxide Grinding Wheel

Tools - N - Abrasives

Ahmedabad

Trusted Seller

Trusted Seller Super Seller

Super Seller8 Years

View More

Roll Grinding Wheels Hardness: 5-10 Mm

Get Best Deal

Tool Room Grinding Wheels Hardness: 5-10 Mm

Get Best Deal

Razor Blade Grinding Wheels Hardness: 5-10 Mm

Get Best Deal

Cylindrical Grinding Wheels Hardness: 5-10 Mm

Get Best Deal

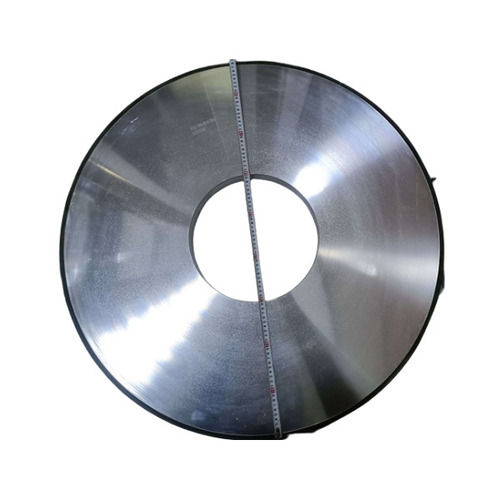

High Performance Grinding Wheel

Price: 300.00 INR/Piece

MOQ50 Piece/Pieces

Product TypeWheel

General UseGrinding

MaterialGalvanized Steel

TypeFeed Grinding Machine, Gear Grinding Machine, Surface Grinding Machine, Cylindrical Grinding Machine

ComputerizedNo

AutomaticNo

Grinding Wheel - Tungsten Carbide, All Size | Coated Silver Round for Industrial Use

MOQ10 Piece/Pieces

UsageIndustrial

ColorSilver

ShapeRound

Product TypeGrinding Wheels

SizeAll size

CoatingCoated

Timus Tooling System Private Limited

New Delhi

Trusted Seller

Trusted Seller Super Seller

Super Seller10 Years

Saw Chain Grinding Wheel - Stainless Steel, 200 mm Size, Pink Color | Eco Friendly, 13 mm Thickness, 1 Year Warranty, Industrial Use

Price: 400 INR/Piece

MOQ1 Piece/Pieces

Product TypeGrinding Wheel

General UseIndustrial

MaterialStainless Steel

Grinding Wheel Size200 mm

FeatureECO Friendly

ColorOther, Pink

Shapura Poonam Engineering Works

Pune

Trusted Seller

Trusted Seller Super Seller

Super Seller9 Years

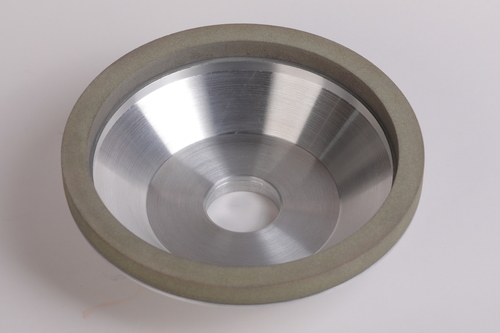

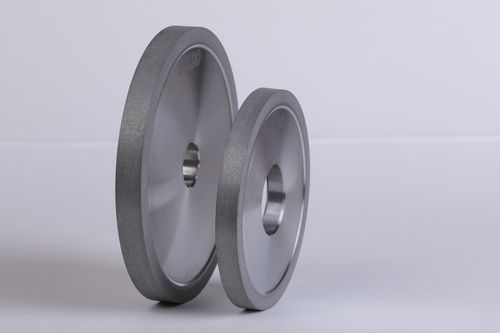

Diamond Grinding Wheels - Resin Bond, Round Shape, Silver/Gray Color | Industrial Use, Ideal for Thermal Spraying and Hard Materials

MOQ2 Piece/Pieces

Usageindustrial use

ShapeRound

Product TypeDiamond Grinding Wheels

ColorSilver, Gray

Zhengzhou Forever Superabrasives Co., Ltd

Zhengzhou

Trusted Seller

Trusted Seller Super Seller

Super Seller3 Years

View More

Electroplated Diamond Cbn Grinding Wheels For Brake Pads Grinding Industrial

Price Trend : 50.00 - 500.00 USD ($)

Resin Diamond Grinding Wheels For Cnc Tool Grinder Industrial

Price Trend : 50.00 - 500.00 USD ($)

Metal Bonded Diamond Grinding Wheels - Custom Size Grooved Teeth, Dry Cutting for Glass and Ceramics

Get Best Deal

Electroplated Cbn Plated Grinding Wheels For Wood Turner Tools Sharpening Industrial

Price Trend : 50.00 - 500.00 USD ($)

Diamond Grinding Wheel - Cutter Type: Wet Cutting

Price Trend : 50.00 - 500.00 USD ($)

Diamond CBN Grinding Wheels

Get Best Deal

Green Tip Grinding Wheel - High Speed Steel, Standard Size, Green Color | Ideal for Bore and Cylindrical Grinding, Precision Applications, and Finishing Tasks

Price: 75 INR/Piece

MOQ100 Piece/Pieces

ShapeRound

Product TypeGreen Tip Grinding Wheel

ApplicationBore and Cylindrical Grinding, Precision Application

Sizecustomize

UsageMetal Cutting

MaterialHigh Speed Steel

View More

White Tool Room Wheel - Application: Grinding

Get Best Deal

Sleek Universal Dc Wheel - Application: Grinding

Get Best Deal

Diamond Grinding Wheel - High Durability Material, Perfect for Precision Grinding and Polishing

Price Trend: 5000-7000 USD ($)/Set

MOQ1 Set/Sets,

HardnessHigh

ShapeFlat, Dish, Cup

BackingSteel Core

Chemical CompositionDiamond Abrasive (C), Steel (Fe), Binder Material

BondingResin Bond, Metal Bond, Vitrified Bond

ToughnessExcellent

Isharp Abrasives Tools Science Institute

Zhengzhou

Trusted Seller

Trusted Seller Premium Seller

Premium Seller11 Years

View More

Aluminium Oxide Grinding Stone Sharpening Stones for Diamond Wheel Dressing - Grit #150 to #220, Custom Sizes and Precisions | Ideal for Glass Edge Processing

Price : 0.4 USD ($)

Disc Grinding Wheels - High-Performance Aluminum Oxide, Precision Engineered for Efficiency and Durability

Price : 5000-7000 USD ($)

Taper Grinding Wheel

Price : 5000-7000 USD ($)

Grinding Wheel Internal Holes Dressing Machine - Color: Grey

Price : 5000 USD ($)

CNC Grinding Wheel Dressing Machine

Price : 5000-7000 USD ($)

Bolt Fastening Grinding Wheel

Price : 5000-7000 USD ($)

Heavy Duty Grinding Wheels - Tungsten Carbide, Multiple Sizes, Grey Color | Designed for Aggressive Material Removal, Superior Durability, and Precise Grinding Results

Price: 3500 INR/Piece

MOQ50 Piece/Pieces

ColorGrey

MaterialTungsten Carbide

ShapeCircular

BladeÃÂ SizeMultipled

Cutting Speed4500 RPM

Operate MethodElectric

Carbide Grinding Wheel - Green Silicon Carbide, 200 x 25 x 31.75 mm, Heat Resistant and Wear Resistant for Extended Lifespan, Balanced Design for Smooth Operation and Reduced Heat Generation

Price: 800 INR/Piece

MOQ100 Piece/Pieces

ColorBlack

UsageUsed for grinding

MaterialHigh Speed Steel

Operate MethodGrinding And Milling Machine

ShapeRound

Size200 x 25 x 31.75mm

View More

100X4Mm Norton Champ Grinding Wheel Hardness: Rigid

Get Best Deal

Norton Expert Grinding Wheel For Metal Use

Get Best Deal

180X6Mm Norton Grinding Wheel Hardness: Rigid

Get Best Deal

Top Rated Products

Grinding Wheel - Tungsten Carbide, All Size | Coated Silver Round for Industrial Use

Timus Tooling System Private Limited

Diamond Grinding Wheels - Resin Bond, Round Shape, Silver/Gray Color | Industrial Use, Ideal for Thermal Spraying and Hard Materials

Zhengzhou Forever Superabrasives Co., Ltd

Diamond Grinding Wheel - High Durability Material, Perfect for Precision Grinding and Polishing

Isharp Abrasives Tools Science Institute

FAQs Related to Grinding Wheels

Who are the top grinding wheels manufacturers in India?

- Arihant Trading Co.

- Linyi Precision Abrasives Co., Ltd.

- Perfect Tools

- Isharp Abrasives Tools Science Institute

- A. K. International

- Micro Products

- National Trading Company

- Timus Tooling System Private Limited

- Laxmipriya Abrasives

- Shapura Poonam Engineering Works

Which cities have the largest number of grinding wheels suppliers?

- Mumbai

- Chennai

- Delhi

- Bengaluru

- Pune

- Hyderabad

- Jaipur

- Kolkata

- Ahmedabad

- Faridabad

- Rajkot

- Gurugram

- Coimbatore

- Vadodara

- Ghaziabad

- Jamnagar

- Bhiwadi

- Udaipur

- Noida

- Nagpur

What kinds of brands are available for grinding wheels?

- Norton Grinding Wheels

- Hitachi Grinding Wheel

- Bosch Grinding Wheels

What is the price range for grinding wheels offered by listed companies?

| Company Name | Currency | Product Name | Price |

|---|---|---|---|

| Kristal Abrasives | INR | Grinding Wheel | 6000 |

| MULJI TRADERS | INR | Industrial Grinding Wheel | 400 |

| SUNCORP INTERNATIONAL LLP | INR | Grinding Disc Wheel | 80 |

| Prime Corporation | INR | Grinding Wheel | 22 |

| Patri Engineers | INR | Grinding Wheel | 5000 |

| Victory Machineries | INR | 3M Green Corps Grinding Wheels | 250 |

| Adwait Enterprises | INR | Grinding Wheel | 242 |

| SHREEJI TRADERS | INR | Grinding Wheel | 500 |

| Shri Sai Techno Engineers | INR | Grinding Wheel | 65 |

| BMS Mechinery Power Tools | INR | 4 Inch Grinding Wheel | 500 |

How many trusted sellers are available for grinding wheels?

- CREDENCE LIVIC INDUSTRIES LLP

- NATIONAL TRADING COMPANY

- LAXMIPRIYA ABRASIVES

- TOOLS - N - ABRASIVES

- ARIHANT TRADING CO.

- TIMUS TOOLING SYSTEM PRIVATE LIMITED

- Shapura Poonam Engineering Works

- ZHENGZHOU FOREVER SUPERABRASIVES CO., LTD

- KRISHNA INDUSTRIAL STORE

- ISHARP ABRASIVES TOOLS SCIENCE INSTITUTE

- Dadu Enterprises

- Shah Brothers

- A. K. INTERNATIONAL

- SHRI NAVNIT C.BAVISHI AND COMPANY

- STANDARD WELDING & TOOLS

- PERFECT TOOLS

- IMPEX ENGINEERING & EQUIPMENTS CO.

- S.H.TRADER

- ADITI ENTERPRISES

- ADR INDUSTRIAL SOLUTIONS LLP

- S. P. Kothari & Co.

- EN AND M TECHNO SALES

- N D PACKAGING

- Micro Products

What is the minimum order quantity for grinding wheels?

Do listed companies have registration & certifications?

- CREDENCE LIVIC INDUSTRIES LLP

- Shapura Poonam Engineering Works

- Shah Brothers

- LINYI PRECISION ABRASIVES CO., LTD.

What is the get latest price feature?

What types of payment methods are accepted by the grinding wheels suppliers?

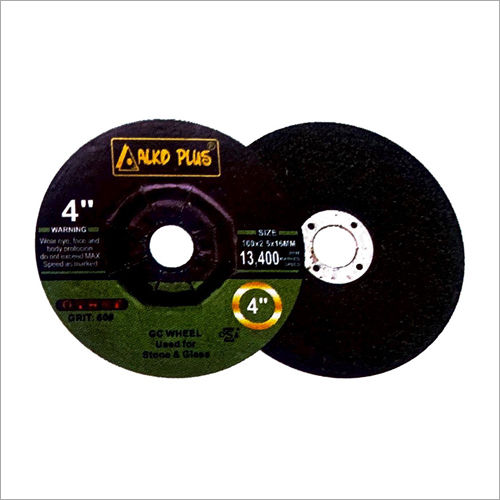

Grinding Cutting Wheel - Metal, 4 Inch, Black | High Efficiency, Sharp and Fast, High Temperature Tolerance for Steel and Alloy Cutting

Price: 60.00 INR/Piece

MOQ200 Piece/Pieces

Product TypeCutting Wheel

General UseGrinding

MaterialMetal

Size4 inch

ColorBlack

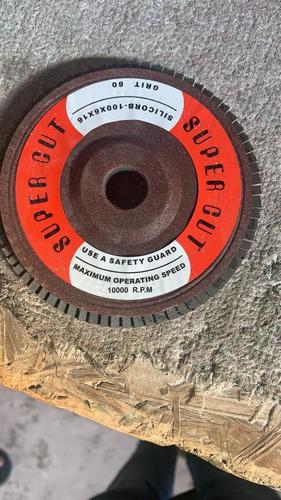

Dc Grinding Wheels - Chemical Composition: No

Price: 18.00 INR/Piece

MOQ200 Piece/Pieces, Piece/Pieces, Piece/Pieces

BondingNO

HardnessHARD

ColorRED,BLACK,GREEN

ToughnessHARD

ShapeRound

Grain TypeNO

View More

Auto Crankshaft Grinding Wheel

Get Best Deal

High Grade Straight Grinding Wheel - 100 mm Dia. Taper Cup Flat Segment A & AA | Reliable, Durable Quality Assurance

Get Best Deal

Flour Mill Grinding Wheels

Get Best Deal

Auto Parts Grinding Wheel

Get Best Deal

350X100X127 A60 Grinding Wheel - Cutting Accuracy: High Precision %

Price : 3540.00 INR

KORE Arc Abrasives - High Grade Raw Material , Long Lasting Performance & Affordable Pricing

MaterialHigh grade

TechnologySuperior

ApplicationGrinding

AbrasiveKORE Arc

PerformanceOptimum

RatesPaltry

Diamond Grinding Wheels - Shape: Round

Price: 1200 INR/Piece

MOQ50 Piece/Pieces

ShapeRound

Product TypeDiamond Grinding Wheels

SizeStandard

ApplicationIndustrial

TextureSmooth

HarnessYes

View More

Diamond Grinding Wheels - Shape: Round

Price : 2200 INR

Diamond Grinding Cup Wheel - Shape: Round

Price : 2300 INR

Grinding Wheels - Application: Industrial

Price : 95 INR

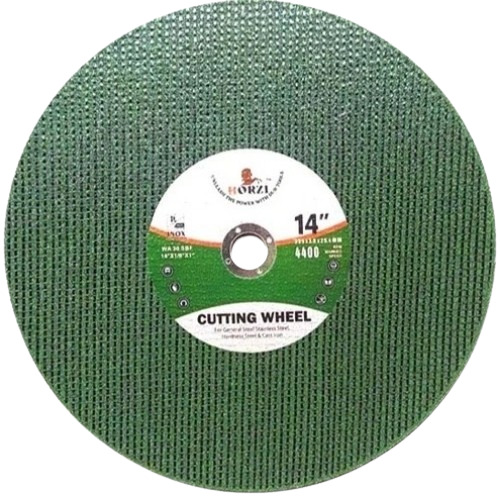

Grinding Wheels - High Speed Steel, 14 Inches Diameter, Black Color, Circular Shape , Electric Operation, 7mm Thickness, Mild Steel Finish

Price: 400 INR/Piece

MOQ100 Piece/Pieces

BladeÃÂ Size14 Inches

Operate MethodElectric

ShapeCircular

MaterialHigh Speed Steel

Product TypeGrinding Wheels

ColorBlack

Impex Engineering & Equipments Co.

Mumbai

Trusted Seller

Trusted Seller9 Years

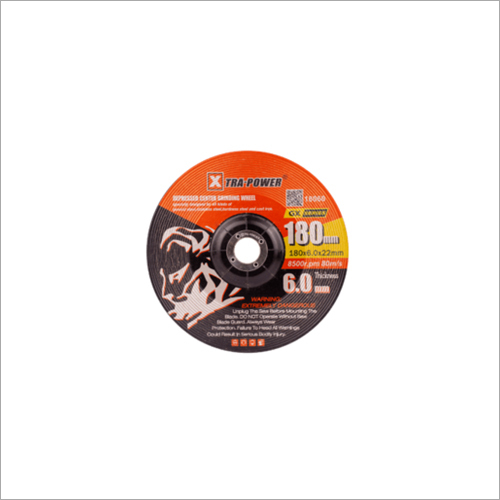

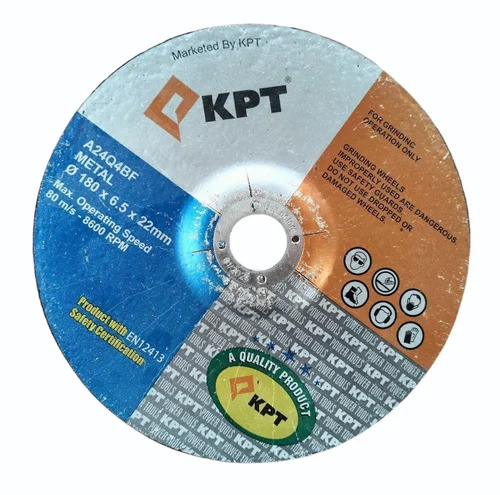

Abrasive Grinding Wheel - 180x6.0x22 mm , Brown Color, 80 m/s Cutting Speed, High Tensile Strength, Excellent Break Resistance

MOQ100 Piece/Pieces

Cutting Speed80 m/s

UsageGrinding & Machinig Operation

ShapeRound

Size180x6.0x22 mm

Product TypeAbrasive Grinding Wheel

ColorBrown

View More

Brown Metal Grinding Wheel

Get Best Deal

XP Round Grinding Wheel

Get Best Deal

JK 7 Inch Grinding Wheel

Get Best Deal

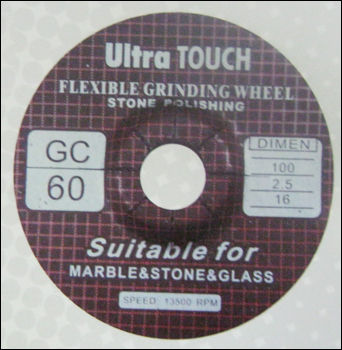

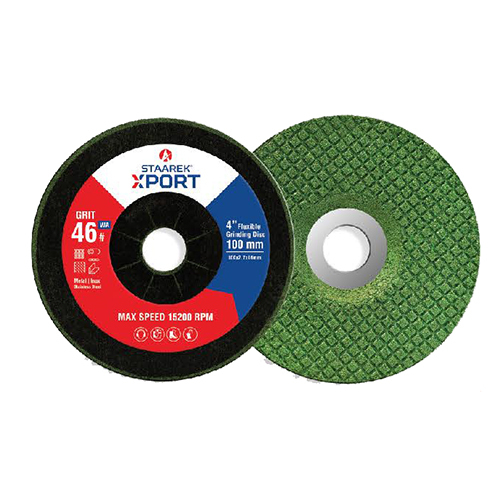

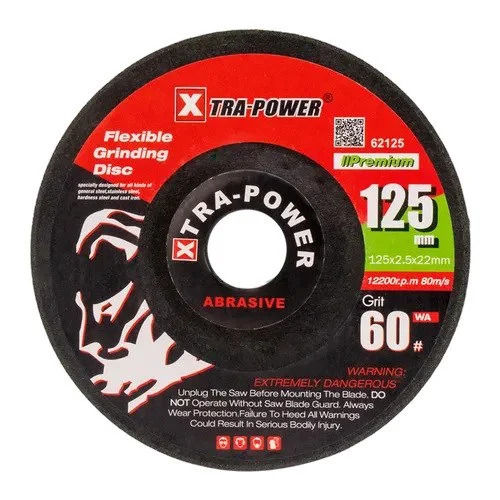

Flexible Grinding Wheel - WA, C, GC Materials, Size 100 x 2.5 x 16mm | Round Shape, Abrasion Resistance, Smooth Texture, Flexible Use in Industry

Price: 60 INR/Piece

MOQ50 Piece/Pieces

HardnessYes

SizeStandard

ColorGreen

UsageIndustrial

ShapeRound

MaterialSS

Grinding Wheel - Color: Grey

MOQ100 Piece/Pieces

ShapeRound

UsageIndustrial

MaterialAbrasive

SizeStandard

Rolls Size50mm

ColorGrey

Diff Options Available Grinding Wheel

MOQ10 Piece/Pieces

FeatureWaterproof, Shrink-Resistant

PatternBrushed, Flocked

Colordiff options available

Fabric Materialsand paper

Usagegrinding iron and marble .

Recommended SeasonAll

Adr Industrial Solutions Llp

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

Code 2342Br-4.0 4Inch Export Grinding Wheel - Material: Aluminum Oxide Or Alumina Zirconia

Price: 19 INR/Piece

MOQ50 Piece/Pieces

BondingResin bond

ShapeRound

UsageGrinding Machine

MaterialAluminum oxide or alumina zirconia

Size4inch

TypeAbrasive Disc

A24Q4Bf Kpt Grinding Wheels - Color: Red

Price: 6939 INR/Piece

MOQ5 Piece/Pieces

ColorRed

ShapeRound

UsageDry Grinding

MaterialMetal

Size180 x 6.5 x 22mm

Cutting - Grinding Wheels - Color: Multicolor

MOQ10 Piece/Pieces

ColorMulticolor

Warranty1 Year

Usage & ApplicationsIndustrial

MaterialStainless Steel

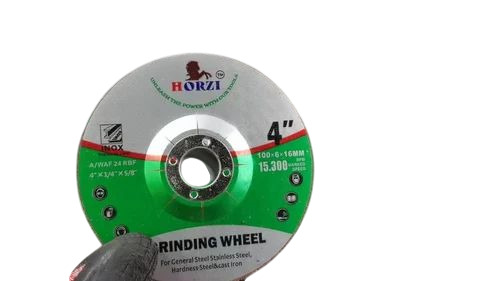

Horzi Grinding Wheels

Price: 24 INR/Piece

MOQ2000 Piece/Pieces

UsageIndustrial

ColorGreen

HardnessSolid

Size4 Inch

ShapeRound

Product TypeStainless Steel

View More

Green Horzi Grinding Wheel

Price : 24 INR

4 Inch Horzi Grinding Wheel - Color: Green

Price : 28.82 INR

Horzi Grinding Wheel - Color: Brown

Price : 24 INR

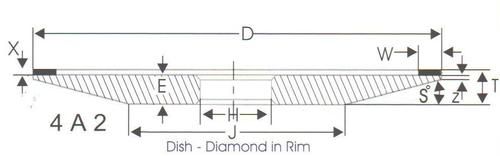

Hybrid CBN Grinding Wheel

MaterialCBN

Diameter (D)150 mm

Width (W)25 mm

Thickness (T)2.5 mm

Dish (E)5 mm

BondVitrified

View More

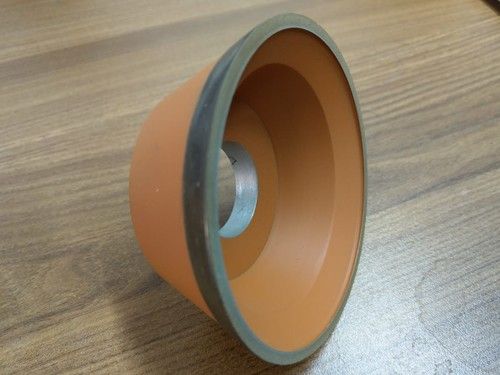

Cup Type Diamond Grinding Wheel

Get Best Deal

Flat Grinding Wheel

Get Best Deal

Diamond Grinding Cup Wheel - Resin Bond, 8m/s to 30m/s Cutting Speed | High Efficiency, Good Quality, Versatile for Stone, Concrete, Ceramic, and Steel

Price Trend : 800.00 - 10000.00 INR

Hybrid Bonded Cbn And Diamond Cup Wheel Grinding

Price Trend : 1000.00 - 15000.00 INR

Diamond Grinding Wheels - Resin, CBN, Vitrified, Hybrid Bond Options | Non-Computerized, Normal CNC Operation

Price : 1000 INR

Diamond and CBN Grinding Wheels - Tailored Precision for Hard Materials, High Efficiency and Quality Finishing

Price Trend : 400.00 - 2000.00 INR

Chainsaw Grinding Wheel - Brown, Round, 10-60 Grams | Ideal for Grinding and Buffing Granite, Marble, and Concrete Surfaces

Price: 10 INR/Piece

MOQ4 , Piece/Pieces

ShapeRound

UsageFor Grinding Use

Product TypeChainsaw Grinding Wheel

Weight10-60 Grams (g)

ColorBrown

Grinding Wheels - High-Quality Abrasive Material, Multiple Sizes Available | Precision Engineered for Superior Performance

Product TypeGrinding Wheels

MaterialAbrasive Grains

Outer Diameter300Mm

Thickness40Mm

Max Speed2000

Bonding AgentResinoid

View More

Cobalt Alloy Grinding Wheel

Get Best Deal

Latest from Grinding Wheels

Popular Grinding Wheels

Client Testimonials & Reviews

SumanKumar

ESSTO ENGINEERING ( UNIT - II )

It is very much profitable for my business. Thanks for this, hope to get same commitment in near future from tradeindia.

BrijeshKuntal

D. B. ENTERPRISES

We are using tradeindia services From Last 9 Years. Tradeindia is a best B2B portal and it helps me out to grow my business online.A They provide very good service and help me a lot to increase my business online.This has helped us to expand our presence All Over India. We look forward to a continual relationship with tradeindia.com and recommended to others, as one of the most organized platform for the promotion of our services.

C.Babu

CM ABRASIVES PVT LTD

We are manufacturers of Coated Abrasive products such as Abrasive Belts, Rolls, Discs etc. For grinding and finishing of Metal, Glass,Leather, Wood etc. We are member of tradeindia.com since last 6 years and very much satisfied with the service of tradeindia team and we wish them all success in their endeavour.

We are very much satisfied with tradeindia.com, it gives us good platform to explore our products and company in domestic market and international as well. We would like to thanks to team tradeindia for making our presence globally.

Grinding Wheels Price List

Product Name | Expected Price |

|---|---|

| Grinding Wheel | 6000 |

| Industrial Grinding Wheel | 400 |

| Grinding Disc Wheel | 80 |

| Grinding Wheel | 22 |

| Grinding Wheel | 5000 |

| 3M Green Corps Grinding Wheels | 250 |

| Grinding Wheel | 242 |

| Grinding Wheel | 500 |

| Grinding Wheel | 65 |

| 4 Inch Grinding Wheel | 500 |

This Data was Last Updated on 2025-12-14

Grinding Wheels Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Arihant Trading Co. Mumbai, India | 17 Years |

Linyi Precision Abrasives Co., Ltd. Linyi, China | 17 Years |

Perfect Tools New Delhi, India | 12 Years |

Isharp Abrasives Tools Science Institute Zhengzhou, China | 11 Years |

A. K. International Mumbai, India | 11 Years |

Micro Products Bhavnagar, India | 11 Years |

National Trading Company Bhiwandi, India | 10 Years |

Timus Tooling System Private Limited New Delhi, India | 10 Years |

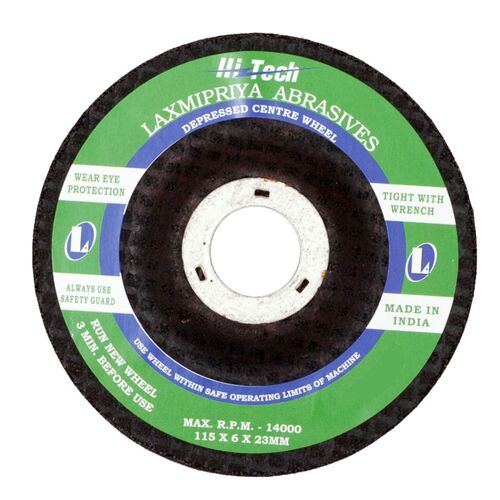

Laxmipriya Abrasives Vasai, India | 9 Years |

Shapura Poonam Engineering Works Pune, India | 9 Years |

Upcoming Tradeshows

CWIEME Shanghai 2026

Wed, 24 Jun, 2026 - Fri, 26 Jun, 2026

INDOMACH Jamshedpur 2026

Thu, 05 Feb, 2026 - Sun, 08 Feb, 2026

Asia Photonics Expo (APE 2026)

Wed, 04 Feb, 2026 - Fri, 06 Feb, 2026

LogiMAT India 2026

Thu, 05 Feb, 2026 - Sat, 07 Feb, 2026

INTERNATIONAL CAFE AND BEVERAGE SHOW (ICBS) 2026

Thu, 07 May, 2026 - Sat, 09 May, 2026

AutoTechnika 2026

Fri, 05 Jun, 2026 - Sun, 07 Jun, 2026

SAIFEE BURHANI EXPO 2025

Fri, 19 Dec, 2025 - Sun, 21 Dec, 2025

Power On 2026

Fri, 23 Jan, 2026 - Sun, 25 Jan, 2026

AGROWORLD EXPO 2026

Fri, 20 Feb, 2026 - Mon, 23 Feb, 2026

Bharat Pharma Expo 2026

Thu, 11 Jun, 2026 - Sat, 13 Jun, 2026

Popular Categories