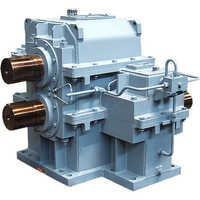

Rolling Mill Machinery

(978 products)

Related Categories

Agarbatti Making Machines

Agricultural Machines & Tools

Bag Closing Machine

Bag Making Machine

Bag Packaging Machines

Banking Automation Products

Bending Machines

Billing Machine

Biscuit Making Machinery

Block Making Machine

Blow Moulding Machines

Box Making Machines

Braiding Machine

Brick Making Machine

Briquettes Making Machines

Briquetting Plants

CNC Machines

Cable Machinery

Carton Folding & Gluing Machines

Cashew Processing Machine

Cement Plant Machinery

Ceramic Machinery

Chapati Making Machines

Chemical Machinery

Chemical Processing Plants

Chuck

Coating Machine

Coil Winding Machines

Coir Machinery

Compression Testing Machines

Concrete Batching Plant

Confectionery Machinery

Construction Machinery

Cotton & Synthetic Spinners

Cutting Machine

Cylindrical Grinding Machinery

Dairy Equipment

Dairy Products Machinery

Decorative Laminate Machinery

Diamond Cutting Blades

Diamond Cutting Discs

Diamond Cutting Machines

Diamond Cutting Tools

Diamond Cutting Wheels

Diamond Grinding Wheel

Diamond Polishing Pads

Diamond Polishing Wheels

Dispenser Machine

Earth Moving Equipment & Machinery

Electrical Cable Machine

Embroidery Machine

Extraction Plants & Machinery

Extruder

Filter Machinery

Fishery Machinery

Flexo Printing Machinery

Flour Mill Machinery & Accessories

Food Processing Machinery

Footwear Machinery

Forest Machinery

Fruit & Vegetable Processing Machine

Gas Generation Equipment

Glass Processing Machines

Granite Processing Machinery

Grinding & Milling Machinery

Home Sewing Machine

Horticulture, Gardening & Irrigation Machinery

Hosiery Machinery

Ice Cream Machines

Ice Cream Plants

Industrial Gas Plants

Industrial Machinery & Parts

Injection Moulding Machine

Jewelry Making Tools & Machinery

Jute Mill Machinery

Knitting Machinery

Knitting Needles

Label & Sticker Labeling Machine

Lamination Machinery

Lamp Making Machinery

Laser Cutting Machines

Lathe Machine

Leather Machinery

Liquid Filling Machines

Machine Tools

Machine Tools Accessories

Machineries

Machinery & Parts

Marine Equipment

Metallic Processing Machinery

Metallurgy Lab Equipment

Mining, Exploration & Drilling Machinery

Mosaic Tiles Machinery

Oil & Gas Field Machinery & Equipment

Oil Expeller

Oil Extraction Machine

Oil Mill Machinery

Oil Refinery Plant

Other Machinery

Oxygen & Nitrogen Gas Plants

PU False Twister

Packaging Machine

Paint Manufacturing Machines

Paper Printing & Book Binding Machine

Paper, Paper Converting Machinery

Pharmaceutical Machinery

Planetary Mixer

Plant & Machinery

Plasma Cutting Machines

Plasma Welding Machines

Plastic Processing Machinery

Plywood Machinery

Polish & Polishing Material/Machinery

Polyurethane Foaming Machines

Pressure Fingers

Printing Ink Machinery

Printing Machinery

Processing Machines & Equipment

Pulverizers

Ribbon Blender

Rice Machinery

Rice Mill Machinery

Road Construction Machinery

Roll Forming Machinery

Rolling Mill Machinery

Rotogravure Printing Machine

Rotomoulding Machines

Rubber Extrusions

Rubber Machinery

Rubber Moulding Machines

Sealing Machine

Seed Processing Machinery

Sewing Machine

Sewing Machine Parts & Accessories

Shearing Machine

Shredding Machine

Shrink Wrapping Machines

Soap Making Machine

Soaps & Detergent Plants

Soda Making Machine

Sorting Machine

Special Purpose Machines

Spinning Machinery

Stamping Machine

Starch and Starch Machinery

Steel Rolling Mills Machinery

Strapping Machines

Stretch Wrapping Machines

Sugar Machinery

Tea & Coffee Machines

Textile & Garment Machinery

Textile Dyeing Machinery

Textile Finishing Machinery

Textile Machinery Spares, Components & Accessories

Textile Printing Machinery

Textile Processing Machinery

Tyres Repair & Retreading Machinery

Universal Testing Machines

Used Machinery

Vending Machine

Waste Tyre Recycling Plant

Water Jet Cutting Machine

Weaving Machinery

Weighbridge

Weighing Machines

Welding Electrode Plant & Machinery

Welding Machine

Wire Drawing Machines

Wire Machinery

Wire Winding Machines

Woodworking Machinery

Worsted Spinners

Explore More Categories

Semi-Automatic Spindle Coupling/Cross Joint

Price: 500.00 - 1500.00 INR (Approx.)/Unit

MOQ - 50 Unit/Units

Type - Spindle Coupling/Cross Joint, Other

Material - Mild Steel

Computerized - No

22 Years

Business Type: Manufacturer | Supplier

UGI ENGINEERING WORKS PVT. LIMITED

Automatic Three Roll Mill Machine

Price: 350000 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Type - Other, Three Roll Mill Machine

Material - Mild Steel, Stainless Steel

Automatic Grade - Automatic

13 Years

Business Type: Manufacturer | Exporter

PRATHAM ENGINEERING

Automatic Cr Reversible Rolling Mill

Price: 5000000 INR (Approx.)/Piece

MOQ - 01 Piece/Pieces

Type - Cold Rolling Mill

Material - Mild Steel

Automatic Grade - Automatic

3 Years

Business Type: Manufacturer | Supplier

HERTZ CONTROLS (INDIA) PRIVATE LIMITED

Indian Inquiries Only

Semi-Automatic Industrial Rolling Mill Machine

Price: 100000 INR (Approx.)/Unit

MOQ - 10 Unit/Units

Material - Stainless Steel

Computerized - No

Automatic Grade - Semi-Automatic

3 Years

Business Type: Manufacturer | Exporter

KALPATECH ENGINEERS AND INDUSTRIES LIMITED

Iron Roller Crusher

Price: 500000 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

10 Years

Business Type: Manufacturer | Exporter

KAMEYO SYSTEMS PRIVATE LIMITED

Automatic Cold Rolling Mill Machinery

Price: 1000000.00 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

Type - Cold Rolling Mill

Material - Stainless Steel

Automatic Grade - Automatic

20 Years

Business Type: Manufacturer | Exporter

VAID ENGINEERING INDUSTRIES

Automatic Precision Wire Rolling Mill Production Line

Price: 6000 INR (Approx.)/Set

MOQ - 1 Set/Sets

Type - Cold Rolling Mill

Material - rolling from round wires into flat&shaped ss wire,carbon steel wire,alloy wire

Computerized - Yes

4 Years

Business Type: Manufacturer | Distributor

SKY BLUER ENVIRONMENTAL TECHNOLOGY CO LTD

Anti corrosive Hand Operated Rolling Mills

Material - Metal

12 Years

Business Type: Manufacturer | Distributor

NILKAMAL INDUSTRIES

Metal Automatic Rolling Mill Machine

Price: 750000 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Type - Cold Rolling Mill

Material - Metal

Computerized - No

1 Years

Response Rate: 85.00%

Business Type: Manufacturer | Exporter

Shivam Industries

Expanded Metal Machine

Price: 550000 INR (Approx.)/Unit

MOQ - 1 Unit/Units

8 Years

Business Type: Manufacturer | Supplier

SHREE JAGDAMBA ENTERPRISES

Semi-Automatic Shaftless Electric Mill Roll Stand

MOQ - 10 Unit/Units

Type - Hot Rolling Mill

Material - Stainless Steel

Computerized - No

2 Years

Business Type: Distributor | Supplier

BarkTechnologies

Automatic Pre Pinching Type Plate Bending Machine

Price: 3500000 INR (Approx.)/Piece

MOQ - 20 Piece/Pieces

Type - Other, Pre Pinching Type Plate Bending Machine

Material - Stainless Steel

Computerized - No

3 Years

Business Type: Manufacturer | Trading Company

VICTORY MACHINERY CORPORATION

Indian Inquiries Only

Automatic Triple Roll Mill Machine

Type - Other, Triple Roll Machine

Material - Heavy Metal

Automatic Grade - Automatic

Business Type: Manufacturer | Supplier

HASAN INDUSTRIES

Hot Rolling Mill

Price: 1 INR (Approx.)/Unit

MOQ - 1 Unit/Units

12 Years

Business Type: Manufacturer | Distributor

HYDRO MECHANIK ENGINEERS

Automatic 3 Roller Hydraulic Pre Pinch Plate Rolling Machine

Price: 1500000 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Type - Other, 3 Roller Hydraulic Pre Pinch Plate Rolling Machine

Material - Mild steel

Automatic Grade - Automatic

2 Years

Business Type: Manufacturer | Exporter

VAHANVATI MACHINE TOOLS

Triple Roll Mill Machine

Price: 5000000.00 - 10000000.00 INR (Approx.)/Unit

MOQ - 1 Unit/Units

3 Years

Business Type: Manufacturer

AAS PROCESS EQUIPMENTS PVT LTD.

Grinding Ball Skew Rolling Hot Rolling Machine for Rolling Ball

Price: 1000.00 - 100000.00 USD ($) (Approx.)/Set

MOQ - 1 Set/Sets

2 Years

Business Type: Manufacturer | Distributor

ANYANG FORGING PRESS MACHINERY INDUSTRY CO., LTD

FRP Pickling Line

Price: 1500000.00 - 5000000.00 INR (Approx.)/Plant

MOQ - 1 Plant/Plants

2 Years

Business Type: Manufacturer | Exporter

SHANKAR FRP PROJECT ENGINEERING

Rolling Mill Machinery Manufacturers | Suppliers in India

| Company Name | Location | Member Since |

|---|---|---|

| Ugi Engineering Works Pvt. Limited | Kolkata, India | 22 Years |

| S M T Machines (India) Limited | Mandi Gobindgarh, India | 21 Years |

| Vaid Engineering Industries | Delhi, India | 20 Years |

| Senior Paper Packing Machinery Mfg. Co. | Amritsar, India | 19 Years |

| Plateroll Industries | Howrah, India | 19 Years |

| Micro Pulverizer Mfg Works | Mumbai, India | 16 Years |

| India Factory | Malerkotla, India | 14 Years |

| Pratham Engineering | Mira Bhayandar, India | 13 Years |

| Creative Carbon Pvt. Ltd. | Ahmedabad, India | 12 Years |

| Nilkamal Industries | Rajkot, India | 12 Years |

What is rolling mill machinery?

Working principle of rolling mill machinery

1. Roll Bending

2. Flat Rolling

3. Ring Rolling

4. Controlled Rolling

5. Forge Rolling

Types of Rolling Mill Machinery

1. Planetary Rolling Mill machinery

2. Continuous Mill Machinery

3. Cluster Rolling Mill Machinery

4. Four-high Rolling mill machinery

5. Three high Rolling Mills

Uses & benefits of rolling mill machinery

There are many benefits to using a rolling mill, and they apply equally to both large and small firms.

1. Perfect for Metalworking

2. Generally Reliable

3. Conveniently Simple to Operate

4. Superior Productivity Rate

5. Spend less on maintenance and operations.

Conclusion

FAQ's: Rolling Mill Machinery

Q. What are the types of rolling mill Machines?

Q. How does a rolling mill machine work?

Q. What is the cost of rolling mill machine?

Related Categories

Related Categories

Agarbatti Making Machines

Agricultural Machines & Tools

Bag Closing Machine

Bag Making Machine

Bag Packaging Machines

Banking Automation Products

Bending Machines

Billing Machine

Biscuit Making Machinery

Block Making Machine

Blow Moulding Machines

Box Making Machines

Braiding Machine

Brick Making Machine

Briquettes Making Machines

Briquetting Plants

CNC Machines

Cable Machinery

Carton Folding & Gluing Machines

Cashew Processing Machine

Cement Plant Machinery

Ceramic Machinery

Chapati Making Machines

Chemical Machinery

Chemical Processing Plants

Chuck

Coating Machine

Coil Winding Machines

Coir Machinery

Compression Testing Machines

Concrete Batching Plant

Confectionery Machinery

Construction Machinery

Cotton & Synthetic Spinners

Cutting Machine

Cylindrical Grinding Machinery

Dairy Equipment

Dairy Products Machinery

Decorative Laminate Machinery

Diamond Cutting Blades

Diamond Cutting Discs

Diamond Cutting Machines

Diamond Cutting Tools

Diamond Cutting Wheels

Diamond Grinding Wheel

Diamond Polishing Pads

Diamond Polishing Wheels

Dispenser Machine

Earth Moving Equipment & Machinery

Electrical Cable Machine

Embroidery Machine

Extraction Plants & Machinery

Extruder

Filter Machinery

Fishery Machinery

Flexo Printing Machinery

Flour Mill Machinery & Accessories

Food Processing Machinery

Footwear Machinery

Forest Machinery

Fruit & Vegetable Processing Machine

Gas Generation Equipment

Glass Processing Machines

Granite Processing Machinery

Grinding & Milling Machinery

Home Sewing Machine

Horticulture, Gardening & Irrigation Machinery

Hosiery Machinery

Ice Cream Machines

Ice Cream Plants

Industrial Gas Plants

Industrial Machinery & Parts

Injection Moulding Machine

Jewelry Making Tools & Machinery

Jute Mill Machinery

Knitting Machinery

Knitting Needles

Label & Sticker Labeling Machine

Lamination Machinery

Lamp Making Machinery

Laser Cutting Machines

Lathe Machine

Leather Machinery

Liquid Filling Machines

Machine Tools

Machine Tools Accessories

Machineries

Machinery & Parts

Marine Equipment

Metallic Processing Machinery

Metallurgy Lab Equipment

Mining, Exploration & Drilling Machinery

Mosaic Tiles Machinery

Oil & Gas Field Machinery & Equipment

Oil Expeller

Oil Extraction Machine

Oil Mill Machinery

Oil Refinery Plant

Other Machinery

Oxygen & Nitrogen Gas Plants

PU False Twister

Packaging Machine

Paint Manufacturing Machines

Paper Printing & Book Binding Machine

Paper, Paper Converting Machinery

Pharmaceutical Machinery

Planetary Mixer

Plant & Machinery

Plasma Cutting Machines

Plasma Welding Machines

Plastic Processing Machinery

Plywood Machinery

Polish & Polishing Material/Machinery

Polyurethane Foaming Machines

Pressure Fingers

Printing Ink Machinery

Printing Machinery

Processing Machines & Equipment

Pulverizers

Ribbon Blender

Rice Machinery

Rice Mill Machinery

Road Construction Machinery

Roll Forming Machinery

Rolling Mill Machinery

Rotogravure Printing Machine

Rotomoulding Machines

Rubber Extrusions

Rubber Machinery

Rubber Moulding Machines

Sealing Machine

Seed Processing Machinery

Sewing Machine

Sewing Machine Parts & Accessories

Shearing Machine

Shredding Machine

Shrink Wrapping Machines

Soap Making Machine

Soaps & Detergent Plants

Soda Making Machine

Sorting Machine

Special Purpose Machines

Spinning Machinery

Stamping Machine

Starch and Starch Machinery

Steel Rolling Mills Machinery

Strapping Machines

Stretch Wrapping Machines

Sugar Machinery

Tea & Coffee Machines

Textile & Garment Machinery

Textile Dyeing Machinery

Textile Finishing Machinery

Textile Machinery Spares, Components & Accessories

Textile Printing Machinery

Textile Processing Machinery

Tyres Repair & Retreading Machinery

Universal Testing Machines

Used Machinery

Vending Machine

Waste Tyre Recycling Plant

Water Jet Cutting Machine

Weaving Machinery

Weighbridge

Weighing Machines

Welding Electrode Plant & Machinery

Welding Machine

Wire Drawing Machines

Wire Machinery

Wire Winding Machines

Woodworking Machinery

Worsted Spinners