Heat Treatment Machine

Price:

Get Latest Price

Brand Name :

Mt

In Stock

Product Specifications

| Input Power | 3 Phase 380V |

| Oscillate Power | 20Kw Max |

| Input Current | 23A Max |

| Oscillate Frequency | 1-20Khz |

| Cooling Water | >0.2Mpa 3L/Min |

| Generator Dimensions | 560*350*550Mm |

| Transformer Dimensions | 550*300*420Mm |

| Features | New Technology, Heating Faster, Economize Energy, Good Effect, Efficiently, Easy Operation, Low Cost |

Product Overview

Key Features

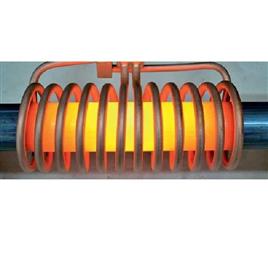

Main Characteristics:

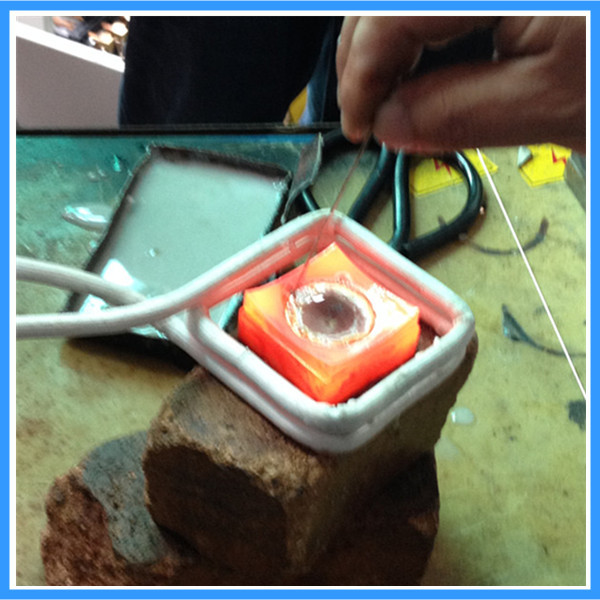

l New technology: replace the traditional gas/flame welding and avoid its insecurity.

l Heating faster: no need for preheating, the welding speed for up-fork is 8-12 seconds/pc. down-fork is 3-5 seconds/pc.

l Economize on power energy: the thermal efficiency is more than 95%.Better energy-saving than other heating methods. Continious power consumption as follow: MT-300Q-25KW/H(degree).MT-600Q35 KW/H(degree).Standby mode no power consumption.

l Good effect: the oxide layer of heating part can be reduced to the lowest (almost no).Thus enhancing the accuracy of the workpiece and to ensure product quality.

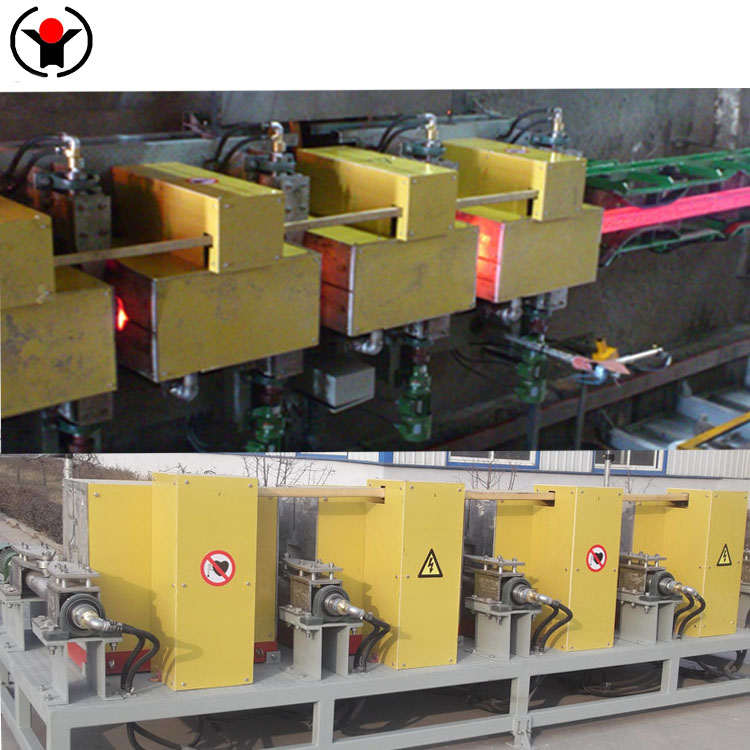

l Efficiently: With automatic setting feature, only one person to complete the operation, thereby reducing the process and operators, greatly enhance the productivity.

l Easy operation: It is easy to learn installation and operation, just need few minutes. Dont need special welding technology. So reducing staff salary.

l Low cost: Compared to traditional welding technology, it saves more than 50% cost.

l New technology: replace the traditional gas/flame welding and avoid its insecurity.

l Heating faster: no need for preheating, the welding speed for up-fork is 8-12 seconds/pc. down-fork is 3-5 seconds/pc.

l Economize on power energy: the thermal efficiency is more than 95%.Better energy-saving than other heating methods. Continious power consumption as follow: MT-300Q-25KW/H(degree).MT-600Q35 KW/H(degree).Standby mode no power consumption.

l Good effect: the oxide layer of heating part can be reduced to the lowest (almost no).Thus enhancing the accuracy of the workpiece and to ensure product quality.

l Efficiently: With automatic setting feature, only one person to complete the operation, thereby reducing the process and operators, greatly enhance the productivity.

l Easy operation: It is easy to learn installation and operation, just need few minutes. Dont need special welding technology. So reducing staff salary.

l Low cost: Compared to traditional welding technology, it saves more than 50% cost.

Company Details

Based in Haryana (India), Malhotra Technologies is a renowned Manufacturer, Supplier and Exporter of a Industrial Hardening Machines. Incorporated in the year 2006, we have gained a rapid growth by becoming a leading brand to avail advance technology based Induction solutions at a reasonable price range. Induction heating is widely used in induction furnace, induction welding, induction brazing, induction sealing and other industrial processes. List of our products consists Induction Heating Machine, Induction Hardening Machine, Electroplating Rectifier, Flexible Blade Hardening Machine, etc. We develop all these products under the strict vig

Business Type

Manufacturer, Supplier

Employee Count

8

Establishment

2007

Working Days

Monday To Saturday

GST NO

06AIYPN2729D1ZZ

Payment Mode

Cash Against Delivery (CAD), Cash Advance (CA)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 06AIYPN2729D1ZZ

Rating

Jhajjar, Haryana

Director

Mr. Naveen Malhotra

Address

Head Office : Gr 36A/2, Ganpati Dham Industrial Area, Jhajjar, Haryana, 124507, India

Report incorrect details