M

Ahmedabad, Gujarat, India|GST 24ABFFM6131Q1ZY

Maruti Investment Steel Cast

GST

24ABFFM6131Q1ZY

Rating

3

Managing Director

Mr Arvindbhai Jivabhai Poshiya

Address

Plot No. 401, Road No.10, Kathwada G.I.D.C., Ahmedabad, Gujarat, 382430, India

About Maruti Investment Steel Cast

Maruti Inv Steel Cast is a reputed manufacturer and supplier that began casting various industrial parts in 2007. We have now developed into one of the best metal casting businesses in the respective domain. Our collection of products includes Steel Investment Casting Parts, Chemical Pump Investment Casting Parts, Automotive investment Casting Parts, Architecture investment Casting Parts and much more items. From a variety of ferrous and non-ferrous metals, we make complicated, high precision, near-net metal parts. Working with us means working with the very best. Along with quick turnaround times for bids, samples, and production work, we also provide integrated, flexible, and responsive investment casting capabilities, machining, value-added services, competitive pricing, design support, and total material integrity.

Investment casting, also known as precision casting or lost wax casting, is a cutting-edge metalforming technique used to create metal parts with the highest level of quality, functionality, and affordability. One disposable pattern is used to create one metal object in the one-to-one process known as investment casting (precision casting). Investment casting (precision casting) can be used to create parts with variable degrees of complexity, in practically any volume, and for the widest range of applications when paired with modern production expertise and technologies.

Mission

Our goal is to deliver high-quality casting by using standardised production techniques.

Quality

Quality is the continuous act of establishing and maintaining connections by identifying, foreseeing, and meeting both explicit and implicit demands. We have always delivered the superior quality products namely Chemical Pump Investment Casting Parts, Steel Investment Casting Parts, Architecture investment Casting Parts, Automotive investment Casting Parts, etc.

Investment Casting Benefits

Greater design freedom (complex intricate shapes can be cast easily, as can assemblies cast as a single piece), a wider range of investment casting alloy options to best suit your investment casting application, improved surface finishes, and more opportunities for cost and weight reduction are all benefits of investment casting. Investment Castings, sometimes referred to as lost wax investment casting, will improve the design and functionality of your mechanical components. Investment castings are available from Consolidated Casting with fine tolerances of +/-.005 inch per inch and 125 RMS machined similar surfaces.

Versatile and Effective Casting Process: Cost Effective Investment Casting

Investment casting (precision casting), a highly adaptable casting technique, has long been thought of as a relatively expensive technique. However, an investment cast component can frequently significantly lower total part production costs when compared to alternative procedures that necessitate heavy welding or machining.

The lost wax casting procedure, also known as investment casting (precise casting), has its origins in China. When American manufacturers used Precision Casting (Investment Casting) to produce high-quality military components during World War II, the technique was introduced into modern industrial application. Investment casting, often known as precision casting, is a process that produces close-tolerance metal parts at prices that are extremely competitive today.

Why Choose Maruti Inv Steel Casting?

Investment casting (precise casting), when done by Maruti Inv Steel Casting (We are one of the most competent and qualified casting specialists around), involves:

Investment Casting-Design

We can die cast steel with the same level of accuracy and surface polish as we do with aluminium and magnesium alloys using the lost wax method. Since we are casting extremely complex pieces in a smaller number utilizing a far less expensive Die. We may assert that the investment castings process can more affordably cast the most challenging pieces. However, we must adhere to the Investment Casting Rules, which are different from the Traditional Casting Rules.

Investment Casting Process

We use a 2D customer-provided investment casting drawing to inspect for mistakes or change using CAD/CAM. After making the necessary revisions in accordance with the requirements of the lost wax casting process, we deliver the drawing to the customer for approval. We provide technical assistance to our clients so they can create cost-effective products based on material and machining cost savings.

Investment casting, also known as precision casting or lost wax casting, is a cutting-edge metalforming technique used to create metal parts with the highest level of quality, functionality, and affordability. One disposable pattern is used to create one metal object in the one-to-one process known as investment casting (precision casting). Investment casting (precision casting) can be used to create parts with variable degrees of complexity, in practically any volume, and for the widest range of applications when paired with modern production expertise and technologies.

Mission

Our goal is to deliver high-quality casting by using standardised production techniques.

Quality

Quality is the continuous act of establishing and maintaining connections by identifying, foreseeing, and meeting both explicit and implicit demands. We have always delivered the superior quality products namely Chemical Pump Investment Casting Parts, Steel Investment Casting Parts, Architecture investment Casting Parts, Automotive investment Casting Parts, etc.

Investment Casting Benefits

Greater design freedom (complex intricate shapes can be cast easily, as can assemblies cast as a single piece), a wider range of investment casting alloy options to best suit your investment casting application, improved surface finishes, and more opportunities for cost and weight reduction are all benefits of investment casting. Investment Castings, sometimes referred to as lost wax investment casting, will improve the design and functionality of your mechanical components. Investment castings are available from Consolidated Casting with fine tolerances of +/-.005 inch per inch and 125 RMS machined similar surfaces.

- Weight Reduction: The highest strength-to-weight ratios are provided by thin wall IC steel castings.

- Premium Casting Tolerances: Maximum strength-to-weight ratios are provided by thin wall IC steel castings.

- Excellent Design Flexibility: Consolidated Casting Corporation can cast complicated shapes, doing away with the need for multi-part fabrications and sub-assemblies. Investment castings can more effectively meet requirements for fit, shape, and functionality. Precisely duplicated in tiny quantities (hundreds, thousands or even millions) There is no need to make accommodations for draught angles or other alternative process restrictions.

- Lower Tooling & Part Cost: Molding tools are needed to create the necessary wax patterns. These tools: are frequently less expensive than conventional diecast tools. They are created more quickly than other types of pattern tools; and - have shorter lead times. Finished product overall costs may be reduced by using multi-cavity automation tooling or single cavity manual operation. It has a 50-year and one million piece theoretical lifespan.

Versatile and Effective Casting Process: Cost Effective Investment Casting

Investment casting (precision casting), a highly adaptable casting technique, has long been thought of as a relatively expensive technique. However, an investment cast component can frequently significantly lower total part production costs when compared to alternative procedures that necessitate heavy welding or machining.

The lost wax casting procedure, also known as investment casting (precise casting), has its origins in China. When American manufacturers used Precision Casting (Investment Casting) to produce high-quality military components during World War II, the technique was introduced into modern industrial application. Investment casting, often known as precision casting, is a process that produces close-tolerance metal parts at prices that are extremely competitive today.

Why Choose Maruti Inv Steel Casting?

Investment casting (precise casting), when done by Maruti Inv Steel Casting (We are one of the most competent and qualified casting specialists around), involves:

- Increased design freedom for pieces that range from being very simple to being extremely complicated

- Offers greater repeatability

- Can make use of a range of alloys

- Produces superior-finish metal parts that are lighter and stronger.

- Lowers the cost of labour, tooling, and machining

- Enables the creation of prototypes very quickly.

- Investment Casting for challenging part applications

- Of fact, not every metal part requirement calls for investment casting (precision casting). However, investment casting (precision casting) offers a tried-and-true and reasonably priced metalforming option for many difficult part applications.

- Marine

- Agriculture

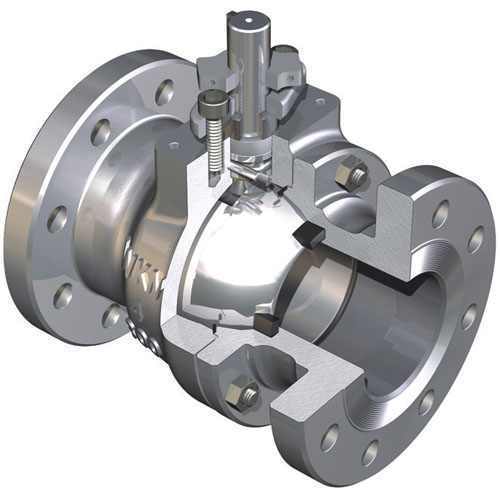

- Industrial Valves

- Industrial Pumps

- Automotive Defense

- Power Plant Equipment

- Aerospace

- Glass And Architecture

- Pharma and Medical

Investment Casting-Design

We can die cast steel with the same level of accuracy and surface polish as we do with aluminium and magnesium alloys using the lost wax method. Since we are casting extremely complex pieces in a smaller number utilizing a far less expensive Die. We may assert that the investment castings process can more affordably cast the most challenging pieces. However, we must adhere to the Investment Casting Rules, which are different from the Traditional Casting Rules.

Investment Casting Process

We use a 2D customer-provided investment casting drawing to inspect for mistakes or change using CAD/CAM. After making the necessary revisions in accordance with the requirements of the lost wax casting process, we deliver the drawing to the customer for approval. We provide technical assistance to our clients so they can create cost-effective products based on material and machining cost savings.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

15

Establishment

2007

Annual Turnover

Rs 6 Crores

Working Days

Monday - Sunday

Payment Mode

Top Products & Services

Buy Online Products

Precision Investment Casting, Cast Iron Body Material, 50-60 Hrc Hardness

1 pack =

1 Set/Sets

Minimum pack :

1

Marine Valve Casting In Carbon Steel Body Material, 50-60 Hrc Hardness

1 pack =

1 Set/Sets

Minimum pack :

1

FAQs : Maruti Investment Steel Cast

What is the year of Estd. of Maruti Investment Steel Cast?-

Maruti Investment Steel Cast was established in 2007.

Who is the Partner of Maruti Investment Steel Cast?+

Mr. Darshan Poshiya is the Partner of the Maruti Investment Steel Cast

What are the main products of this company?+

Company deals in Copper Alloy Casting Parts, High Chrome High Carbon Investment Casting Parts, Precision Investment Casting Parts, Turbine Pump Investment Casting, Automotive Alloy Parts Investment Casting Parts, Industrial Water Pump Investment Casting Parts etc.

What is the business location of Maruti Investment Steel Cast?+

Maruti Investment Steel Cast operates from Ahmedabad, Gujarat, India.

How many different products are listed for this company?+

Presently more than 37 products are listed among different product categories on Tradeindia.com.

What are the main categories in which the company is mapped?+

The company is mapped in stainless steel investment casting,precision investment casting,Stelite parts,gunmetal parts,hardware spare part etc.

View More Products From This Seller

Seller Details

Rating

3

Managing Director

Mr Arvindbhai Jivabhai Poshiya

Address

Plot No. 401, Road No.10, Kathwada G.I.D.C., Ahmedabad, Gujarat, 382430, India

Exporters In AhmedabadRegister your

Company

Popular Products

Human HairForklift TrucksServo Voltage StabilizerBasmati RiceBackhoe LoaderCarry Bag Making MachineDrum LifterElectric StackerScissor LiftsIndustrial Vibrating ScreenRotameterFlowmeterRotary Air CompressorIndustrial Eto SterilizerRice Packaging MachinesShredding MachineHammer MillAutomatic Labelling MachineDiesel ForkliftAerial Work PlatformStorage Rack SystemEpoxy ResinMild Steel BarStainless Steel SheetsStainless Steel StripsBag Filling MachinesAsphalt PlantsSlat ConveyorOintment PlantPlanetary MixersLadies KurtisLed LightsCctv CameraBall ValveAnti Cancer MedicineAir CompressorIncense SticksSolar LightsGoods LiftsVitrified TilesStainless Steel CoilsPvc PipesPvc Pipe FittingsUpvc PipesUpvc Ball ValvePipe Elbows