- Tradeindia

- J. H. Engineering

Ahmedabad, Gujarat, India

J. H. Engineering

Rating

3

Proprietor

Mr NISARG B Patel

Address

Plot No. 71/13, Phase-1, G.I.D.C. Vatva, Ahmedabad, Gujarat, 382445, India

About J. H. Engineering

Business Type

Exporter, Manufacturer, Supplier

Employee Count

11

Establishment

1993

Working Days

Monday - Sunday

Buy Online Products

HSS Screws Barrel

1 pack =

1

Minimum pack :

60

Parallel Twin Screw & Barrel

1 pack =

1 Pair/Pairs

Minimum pack :

60

Barrier Screw - EN41B Nitro-Alloy Steel, Non-Corrosive and Sturdy Design

1 pack =

1

Minimum pack :

1

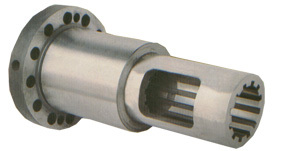

Nitrided Grooved Sleeve

1 pack =

1 Piece/Pieces

Minimum pack :

16

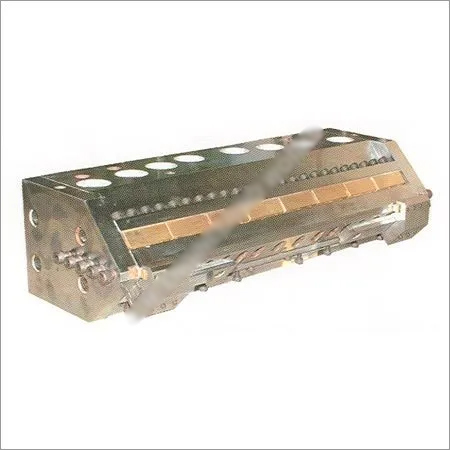

T Die For Woven Sack Tap Plant

1 pack =

1

Minimum pack :

1

Die Component for PVC Pipe Plant

1 pack =

1

Minimum pack :

60

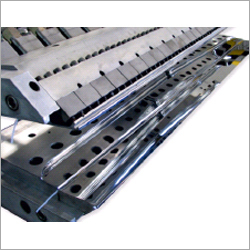

Sheet Extrusion Dies

1 pack =

1

Minimum pack :

1

Twin Screw

1 pack =

1 Piece/Pieces

Minimum pack :

60

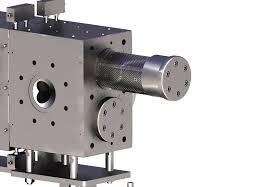

Screw & Barrel For Injection Moulding Machine

1 pack =

1

Minimum pack :

60

Screws Barrel for Woven Sack Plant

1 pack =

1 Pair/Pairs

Minimum pack :

60

Gas Vented Screw & Barrel

1 pack =

1

Minimum pack :

1

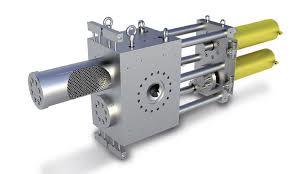

Twin Screw Barrel

1 pack =

1 Pair/Pairs

Minimum pack :

1

FAQs : J. H. Engineering

View More Products From This Seller

Popular Products in Cities

Sheet Metal Dies in Ahmedabad|

Die Cast Components in Ahmedabad|

Plastic Processing Equipment in Ahmedabad|

Woven Sack Machine in Ahmedabad|

Industrial Die Casting Components in Ahmedabad|

Twin Screw Barrel in Ahmedabad|

Parallel Twin Screw in Ahmedabad|

Ring Plunger Set in Ahmedabad|

Mono Filament Plants in Ahmedabad|

Machine Spare Part in Ahmedabad|

Industrial Nozzles in Ahmedabad|

Seller Details

Rating

Proprietor

Mr NISARG B Patel

Address

Plot No. 71/13, Phase-1, G.I.D.C. Vatva, Ahmedabad, Gujarat, 382445, India

Exporters In AhmedabadPopular Products

Human HairForklift TrucksServo Voltage StabilizerBasmati RiceBackhoe LoaderCarry Bag Making MachineDrum LifterElectric StackerScissor LiftsIndustrial Vibrating ScreenRotameterFlowmeterRotary Air CompressorIndustrial Eto SterilizerRice Packaging MachinesShredding MachineHammer MillAutomatic Labelling MachineDiesel ForkliftAerial Work PlatformStorage Rack SystemEpoxy ResinMild Steel BarStainless Steel SheetsStainless Steel StripsBag Filling MachinesAsphalt PlantsSlat ConveyorOintment PlantPlanetary MixersLadies KurtisLed LightsCctv CameraBall ValveAnti Cancer MedicineAir CompressorIncense SticksSolar LightsGoods LiftsVitrified TilesStainless Steel CoilsPvc PipesPvc Pipe FittingsUpvc PipesUpvc Ball ValvePipe Elbows