Chennai, Tamil Nadu, India|GST 33AABCG2902K1ZY

Goodrich Gasket Pvt. Ltd. - Chennai

GST

33AABCG2902K1ZY

Rating

3

Jt. Managing Director

Mr. Arun Rathod

Address

40, Velichai Village, Vandalur-Kelambakkam Road, Chennai, Tamil Nadu, 600048, India

About Goodrich Gasket Pvt. Ltd.

About Us

Established in 1987, Goodrich Gasket Private Limited is a part of Flosil Group, a business conglomerate which is engaged in the manufacturing, oil and gas, defence technology, renewable energy, etc. and has been producing various kinds of Industrial Gaskets for petroleum refinery and other industrial projects. It has a manufacturing facility of 196,000 sq. Ft. Equipped with fabrication shop and machinery shop in Chennai and is furnished with latest machines, handling facility and expert staff.

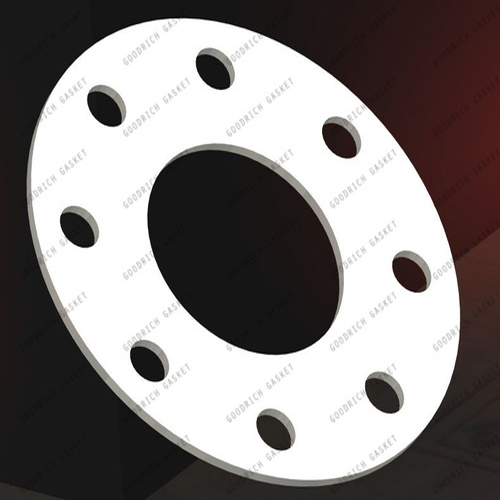

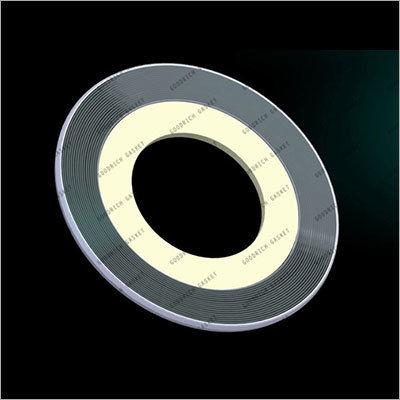

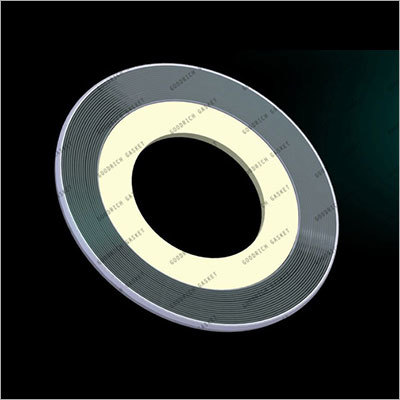

Enriching on the vast industry experience, we have been manufacturing zero defect Spiral Wound Gaskets, Ring Joint Gaskets, etc. The entire product line is rigorously tested on various parameters before it is out in the market. The attributes of high strength, accurate dimension and fine surface finish make our products are hugely demanded across India and international market. We engineer our Tanged Insert Graphite Gaskets, Metal Bonded Rubber Gaskets, and allied products are engineered to ensure high performance as well as suit specific application requirements.

By constantly supplying quality approved products to our valued patrons, we are able to gain their trust. We have with us expert and qualified team of quality inspectors who supervise production process. Customers can avail products in different specifications at competitive market rate.

Our Product Range Comprises:

- All Types of Industrial Gaskets like:-

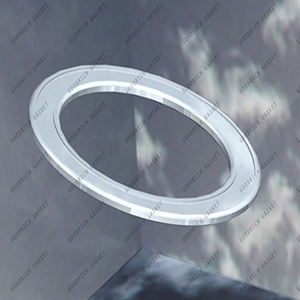

- API Ring Joint Gasket (Ring Type Joint Gaskets, RTJ Gaskets, Ring type joint)

- Tanged Insert Graphite Gaskets

- Metal Bonded Rubber Gaskets

- Spiral Wound Gasket (SPW Gaskets) & Low Stress Gasket

- Metal Double Jacketed, Heat Exchanger Gaskets, Metal Single Jacketed Gaskets,

- Kammprofile Gasket, (Kammprofile Gaskets, Serrated Gaskets, Cam profile gaskets)

- Insulating Flange Kit Gaskets (Insulating kits, Insulation kits)

- Corrugated Metal Graphite Gasket

- Non Asbestos Gasket Sheets (Asbestos Free Gaskets, CNAF gaskets)

- Metal Gaskets (Metallic Gaskets)

- Metal Reinforced Graphite Gasket

- PTFE / Expanded PTFE Gasket, Gasket Sheets, Rods

- Lens

Type Gasket, Precision Machined Components, Bridge-Man Gasket, Sandwich

Gaskets, Mica Gaskets, Delta Gasket, Metal Valve Bonnet Seat Rings,

Compressed Braided Packing, Ropes, Tapes - High Temperature Gaskets / Gasket Materials

- High Pressure Gaskets / Gasket Materials

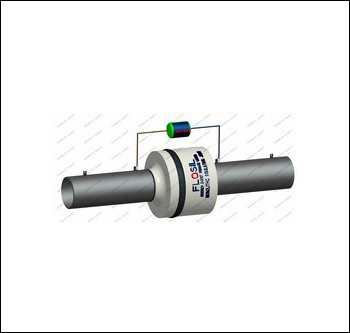

- Monolithic Insulating Joint, Insulating Pipeline Joints, Insulation Joints, Isolating Joints

- Envelope Gaskets

- Flexible Graphite Gaskets / Gasket Sheets / Packings

- Rubber Gaskets / Gasket Sheets / Tapes

- API 6A & API 17D Flanges,

- API 17D -Studs & Nuts (Bolt & Nut, Grade B7 Bolt, Grade 2H Nut, Grade B7/2H Nuts & Bolts)

- API 6A Bull Plugs, API 6A Valve Removal Plugs etc.

We

possess competence in emergency as well as shut down gasket

requirements along with round the clock assistance to successfully meet

our clients requirements. This has helped us establish associations with

our clients.

Some

of our valued clients are: FLOWSERVE, GEA, HYDRIL, CAMERON, TYCO, BHEL,

IOCL, HPCL, BPCL, SAMSUNG ENGINEERING, FOSTER WHEELER, PETRON, ESSAR,

JINDAL’S, TATA’S, EMERSON, CAIRN, SHELL, TEMA, RELIANCE GROUP, GAIL,

EIL, API, LLOYDS, ONGC, ISRO, SCHLUMBERGER, SAIL, AUDCO, NTPC, L&T

etc.

Our quality management system has been approved and upgraded to ISO 14001, ISO 9001:2008, API-Q1 and OHSAS18001 version.

In

addition to our head offices in Chennai, we also have zonal offices in

Hyderabad, Delhi and Mumbai with oversee stocking facilities and sales

office across the globe which aids us in catering to more than 32

countries and delighting more than 3000 clients worldwide.

Continuous

technical upgradation of the facilities and individuals enable us in to

ensure competitive delivery time for both standard and non-standard

products.

Our

products are supplied through reliable national/international sources

with 100% guarantee and products compliance with manufacturing standards

and clients specifications.

STRENGTHS

Emergency & Shut down requirements

- Operation facilities open 24X7 to meet clients emergency and shut down requirements

Performance and reliability

- Experience of more than two decades of manufacturing Gaskets and consistent Investment in modern manufacturing technology

Integrated manufacturer-supplier

- Total control over all critical processes inclusive of raw materials

- Chosen by reputed Oil majors and EPC contractors

Design and Engineering capability:

- Highly skilled team of engineers for designing products with high performance

- Skills to design products with special requirements

- Customized product development – working in close coordination with the user groups

Quality Assurance Program:

- Authorized by international inspection agencies as well as end users

- Gasket performance surpasses many international standards

Variety of products and Wide range:

- Special sealing and selection requirements for the end users

- Gaskets are made of Soft Iron, F5, 304, 304L, 316, 316L, 316Ti, 321, 347

- MONEL® 400, Inconel® 600, 625, Incoloy® 800, 825, Nickel 200, Titanium, Hastelloy, Copper, Brass, Duplex, Super Duplex etc.

Wide distribution network:

- Association with the renowned distributors across the globe

- Availability of Gaskets from different locations including back up inventory at factories

Technical Support and On-Site Advice

Our

rich industry experience in manufacturing, extensive research as well

as new product development is mainly focused towards delivering new

material and products that meet upcoming fluid sealing requirements.

They also play an important role in effectively solving sealing problems

for specific clients.

We

provide On-site advice through highly technical team. Goodrich Gasket

has specialized knowledge, practical industry experience and technical

facilities to solve all fluid sealing problem for our clients.

Projects & International Marketing Team

Our

"Projects & International Marketing Team” delivers the best service

to both Indian & global engineering as well as construction

industry.

Significant

investment in plant infrastructure enables the company to produce top

quality components, while maintaining optimum production capacity; a

vital requirement to meet the demands of large scale EPC business.

OUR ENVIRONMENT - MAKE A DIFFERENCE

Effective

environmental practices are important to company’s long-term success

and continued growth and forms an integral part of organization's core

values.

Every

product manufactured or distributed is specifically designed to ensure a

comfortable coexistence between production, development, and/or

distribution activities.

Goodrich

Gasket incorporates quality, health as well as safety objectives as

core organiztaion values and is dedicated to meeting the highest

standards of HSE performance.

Our

dedication to deliver quality products as well as services along with

supporting a safe work environment is visible in our performance in our

designs, in the field, and in the office.

Our

departments of Health, Safety, Environment and Quality are dedicated to

maintaining these commitments and are constantly guiding Goodrich

Gasket to attain its ultimate goals of zero incidents while achieving

high client satisfaction.

Our Integrated Management System (IMS) is specifically designed to meet the requirements of various standards, such as:

- ISO 9001

- OHSAS 18001

- API SPEC. Q1

- ISO 14001

We

are committed to attain complete customer satisfaction by developing

quality products, on time delivery with competitive prices and

continuous improvements in process, product as well as system.

All

contracts and purchase orders are thoroughly reviewed by in-house sales

personnel. Special engineering and quality requirements are assessed by

concerned departments to assure client specifications are with the

supplied product.

It encompasses all the elements like contract review, inspection, training, and manufacturing, testing and shipping.

All

employees are regularly trained for their specific job requirements. In

addition, training requirements are reviewed every year by concerned

department supervisors for all employees and records are properly

maintained.

All

orders with special engineering and quality requirements are subjected

to Final assessment by qualified and experienced Q.A. Technicians.

Sampling inspection as well as certifications is prepared as per the

clients specific orders. Moreover, complete traceability is assured for

all products that comprise raw material certifications.

We

are also been regularly evaluated and quality tested by a various

industry bodies and individual clients - including multinational

corporations, utilities as well as government organizations.

Key factors that contributes to Goodrich Gasket’s success:

- Advanced high-capacity robotic manufacturing processes

- Professional after-sales service

- Superior and unrivalled gasket technology

- Highly experienced engineers and operators

- Highly trained Quality Personnel, including XRF PMI testing

Business Type

Exporter, Manufacturer, Supplier

Employee Count

250

Establishment

1987

Working Days

Monday - Sunday

Top Products & Services

FAQs : Goodrich Gasket Pvt. Ltd.

View More Products From This Seller

Seller Details

Rating

Jt. Managing Director

Mr. Arun Rathod

Address

40, Velichai Village, Vandalur-Kelambakkam Road, Chennai, Tamil Nadu, 600048, India

Popular Products

Human HairForklift TrucksServo Voltage StabilizerBasmati RiceBackhoe LoaderCarry Bag Making MachineDrum LifterElectric StackerScissor LiftsIndustrial Vibrating ScreenRotameterFlowmeterRotary Air CompressorIndustrial Eto SterilizerRice Packaging MachinesShredding MachineHammer MillAutomatic Labelling MachineDiesel ForkliftAerial Work PlatformStorage Rack SystemEpoxy ResinMild Steel BarStainless Steel SheetsStainless Steel StripsBag Filling MachinesAsphalt PlantsSlat ConveyorOintment PlantPlanetary MixersLadies KurtisLed LightsCctv CameraBall ValveAnti Cancer MedicineAir CompressorIncense SticksSolar LightsGoods LiftsVitrified TilesStainless Steel CoilsPvc PipesPvc Pipe FittingsUpvc PipesUpvc Ball ValvePipe Elbows