Surat, Gujarat, India

Advanced Abrasives Asia-Pacific

Partner

Mr. Nilesh Jariwala

Address

Building no- 306, A-Wing, Tirupati Plaza,near atwa gate, Nanpura, Surat, Gujarat, 395001, India

About Advanced Abrasives Asia-Pacific

For industrial purposes, we are providing a range of super abrasives with high quality standards and industry leading prices......

Advanced Abrasives is a rapidly growing manufacturing and processing base for wet and dry diamond powders, compounds and slurries. With more than 40 years collective experience, we provide our customers with state-of-the-art superabrasive products.

About Advanced Abrasives Corporation

We process these superabrasive products in a variety of methods to meet customer specifications in order to satisfy a diverse range of applications. Highly regarded globally for its custom diamond powders, diamond slurries and pastes, Advanced Abrasives serves a diverse customer base ranging from small businesses to Fortune 500 companies. We are inspired by the highest principles of integrity, honesty, commitment, and accountability in all of our endeavors and decisions.

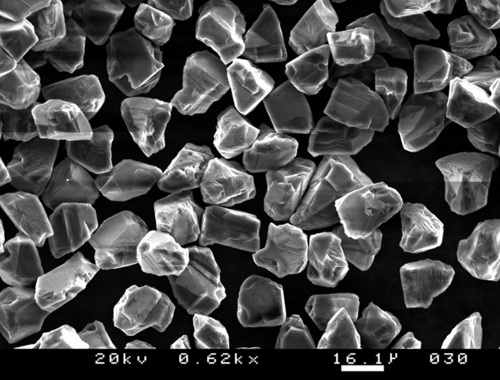

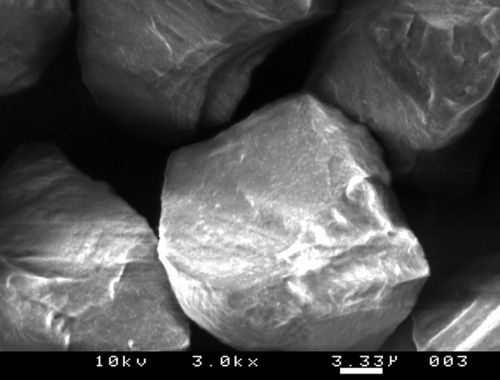

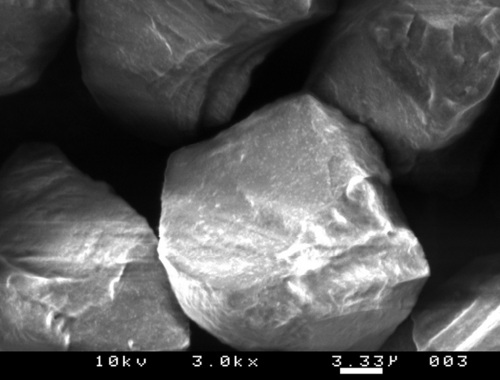

Advanced Abrasives is a manufacturing and processing base for a product portfolio that includes wet and dry diamond powders, compounds and slurries. These products are processed in a variety of methods to "Customer Specific Specifications" to satisfy a diversified range of applications worldwide. All products are manufactured under a controlled and documented manufacturing system.

Our expert team of micronizers has over 40 years of combined experience in the superabrasive industry. Our marketing arm stretches worldwide with representatives in the US, Europe, and Asia.

We continuously monitor new products and processes being designed in the world markets. This allows us to develop superabrasive strategies and solutions to stay ahead of the curve for all of your next generation products and applications.

Our Mission

To provide customers with state-of-the-art superabrasive products, we are inspired by the highest principles of integrity, honesty, commitment and accountability in all of our endeavors and decisions; and work with our customers to achieve superior quality products in a timely, cost effective manner while in a controlled environment. Our result-driven service philosophy and unsurpassed attention to detail amount to world-class industry-leading solutions to help our customers.

Abrasives are widely demanded for cutting, adjusting, grinding and polishing purposes in various industries. Advanced Abrasives Asia Pacific is offering super abrasives with high quality standards. Established in the year 1999, we are one of the leading manufacturers and exporters of diamond synthetic powder and others. Our range includes:

- Diamond Products

- Diamond Synthetic Powder

- Diamond Abrasives

- Diamond Slurries.

We make optimum use of our advanced infrastruture with our quality system to monitor and control the entire micronizing process from beginning to end. To maintain premium quality in each lot, modern processes are performed on each batch and retained for traceability, statistical analysis, and future reference. All critical measurement equipment are monitored and calibrated using standard and statistical process control.

Our efficient and skilled team of micronizers has a rich experience of over 40 years in the super abrasive industry. Their hard work help us to deliver our products to the clients within the stipulated time.

We can customize our product range through different methods according to clients' specifications. All products are manufactured under a controlled and documented manufacturing system. We continuously monitor new products and processes being designed in the world markets. This allows us to develop suitable strategies and solutions to stay ahead of all our competitors. Following are the processes through which our mesh to micron materials go through before becoming an advanced abrasives finished product:

- Mesh material is sourced from a supplier based on crystal type and size

- A representative sample from a large feed batch is tested

- Once received it is compared against the representative sample

- The material is milled based on specific parameters of size and shape

- It goes through a rough classification step which is designed to classify and remove undesirable shapes

- The diamond/cBN undergoes a two stage process of high temperature cleaning

- The feed is then analyzed for rough sizing, shape and quantity

- It is then classified to a unique specification and monitored using various particle size distribution techniques

- Once the desired distribution is achieved, the product goes through an oversize control process

- The diamond/cBN is then checked once again for the proper particle size distribution

- The product enters an ion reduction process

- It is put into a controlled drying environment

- Once dry, it is bottled, labeled and put through Quality Control for finished product approval by testing and certifying all attributes of the Product and Lot Certification.

- Particle size distributions (PSD)

- Shape characteristics through milling/shaping or in the synthesis phase

- Altered pack densities through compounding

- Nanometer and sub micron products in an agglomerate free solution (water or oil)

- Diamond-Diamond coatings

- Compound and slurry formulas

- Surface preparation compatible with your process

- Packaging and labeling.

The vision and leadership of our mentor, Mr. Nilesh Jariwala has helped us achieve good reputation and growth in the industry. Due to the quality of our super abrasives and our commitment towards clients, we have achieved a wide client base in India and in the international markets including USA, Europe, and Asia.

Quality Control and Customized Processing

Advanced Abrasives utilizes state of the art equipment with a stringent quality system to monitor and control the entire micronizing process from beginning to end. To ensure consistency from lot to lot, measurement techniques capable of quantifying the products' characteristics are performed on each batch and retained for traceability, statistical analysis and future reference. All critical measurement equipments are monitored and calibrated using standard and statistical process control.

Particle Size Measurement

Particle Size Distribution (PSD) is one of the most critical characteristics of our superabrasive products. The PSD affects the material removal rate, surface finish and packing density. Advanced Abrasives incorporates many different techniques and instruments to measure the distribution characteristics. This will ensure consistent products from lot to lot, leaving the guess work and variability out of the equation for the end user.

Advanced Abrasives incorporates the following particle size measurement equipment:

Instrument | Measurement Technique |

|---|---|

Horiba - LA 910 | Laser light scattering |

Coulter - Multisizer 3 | Electric sensing zone |

Microtrac - S3000 / X-100 | Laser light scattering |

CPS | Centripetal force and laser |

Image Pro - Image Analysis | Microscopy |

Business Type

Exporter, Manufacturer, Distributor

Employee Count

5

Establishment

2003

Payment Mode

Top Products & Services

FAQs : Advanced Abrasives Asia-Pacific

View More Products From This Seller

Seller Details

Partner

Mr. Nilesh Jariwala

Address

Building no- 306, A-Wing, Tirupati Plaza,near atwa gate, Nanpura, Surat, Gujarat, 395001, India

Exporters In SuratPopular Products

Human HairForklift TrucksServo Voltage StabilizerBasmati RiceBackhoe LoaderCarry Bag Making MachineDrum LifterElectric StackerScissor LiftsIndustrial Vibrating ScreenRotameterFlowmeterRotary Air CompressorIndustrial Eto SterilizerRice Packaging MachinesShredding MachineHammer MillAutomatic Labelling MachineDiesel ForkliftAerial Work PlatformStorage Rack SystemEpoxy ResinMild Steel BarStainless Steel SheetsStainless Steel StripsBag Filling MachinesAsphalt PlantsSlat ConveyorOintment PlantPlanetary MixersLadies KurtisLed LightsCctv CameraBall ValveAnti Cancer MedicineAir CompressorIncense SticksSolar LightsGoods LiftsVitrified TilesStainless Steel CoilsPvc PipesPvc Pipe FittingsUpvc PipesUpvc Ball ValvePipe Elbows