Hydrocarbon Recovery Systems

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Stainless steel |

| Dimensions | Variable |

| Capacity | 10-1000 Nm³/h |

| Pressure | 50-500 bar |

| Temperature | -20-100°C |

| Recovery rate | 90-99% |

| Usage | Refinery, Petrochemical, Fertilizer, Natural gas industries |

| Features | Hydrocarbon recovery, Gas purification, Energy efficiency, Cost savings, Improved yield, Reduced emissions |

Product Overview

Key Features

* Hydrocarbon Recovery System is used to recover valuable hydrocarbons and to purify the light gas for reuse within the process. Applications for Vapor Sep are found throughout the Refinery, Petrochemical, Fertilizers, Natural gas industries.

* Vapor Sep process combines membrane vapor separation with compression condensation. The feed gas is compressed and cooled, condensing a portion of the hydrocarbons.

* The liquid is recovered for reuse and the remaining gas, which still contains a significant amount of hydrocarbon is fed to the Vapor Sep membrane. The membrane separates the gas into two streams: a permeate stream containing most of the hydrocarbons and a residue stream which contains the purified light gas.

* The permeate is recycled to the inlet of the compressor while the residue stream is vented or reused. Some Vapor Sep systems are even simpler, consisting of only membranes.

* In conventional membranes, separation is accomplished primarily by differences in diffusion rates due to differences in molecular size. In contrast, the Vapor Sep membrane separates on the basis of solubility.

Company Details

Focusing on a customer-centric approach, Mixrite Engineering Company has a pan-India presence and caters to a huge consumer base throughout the country. Buy Chemical Machinery in bulk from Mixrite Engineering Company at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

GST NO

27AAXFM6165B1ZX

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27AAXFM6165B1ZX

Mumbai, Maharashtra

Manager

Mr Nishith K. Kumbhani

Address

Plot No-22, New Apollo Estate, Mogra lane, Andheri East, Mumbai, Maharashtra, 400069, India

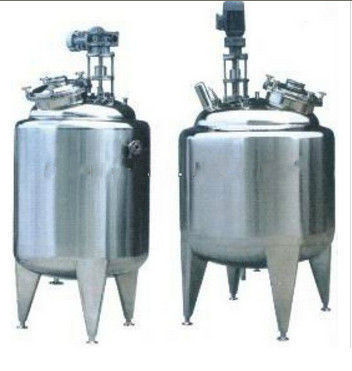

jacketed reactors in Mumbai

Report incorrect details