- Tradeindia

- Machineries

- White Coal Machine

White Coal Machine

(25 products)Coal Grinding Machine - General Use: Commercial

Price: 13280 INR/Unit

MOQ1 Unit/Units

Product TypeCoal Grinding Machine

UsageIndustrial

ColorOther, Silver

Confider Industries Llp

Ahmedabad

Trusted Seller

Trusted Seller3 Years

Super Seller

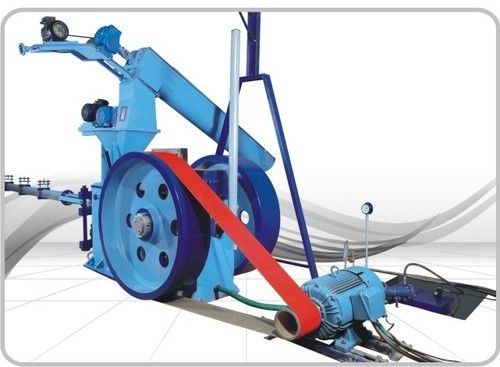

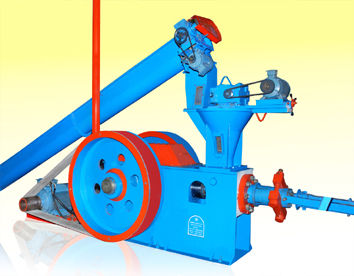

Super SellerBriquette Making Machine Briquette Size: 90 Mm

Price: 500000 INR/Unit

MOQ1 Unit/Units

Product TypeMichanical Piston press

General Usemaking briquettes / bio coal / white coal

Production Capacity1200-2000 (according to raw materials) Kg/hr

White Coal Manufacturing Machine

Product DescriptionFrom our huge variety of products, we are Exporting, Manufacturing and Supplying the best great collection of White Coal Manufacturing Machine in Rajkot this is widely famend among clients all throughout the united states of america. This product is manufactured using the first-class best raw materi

Radhe Engineering Company

Rajkot

Trusted Seller

Trusted Seller1 Years

Premium Seller

Premium SellerFully Automatic Badami Coal Machine - Power Source: Electricity

Price: 127500.0 INR/Unit

MOQ1 Unit/Units

Power SourceElectricity

Operating TypeAutomatic

Surface TreatmentCoated

White Coal Briquette Machine

Price: 1790000.00 INR/Plant

MOQ1 Plant/Plants

Product TypeBiomass Briquetting Machine, Other

Weight (kg)8.00 Tonne

Usage & ApplicationsIndustrial

Brown Coal Ball Mill Machinery

Product DescriptionCatering to the needs of a large score of customers in the industry, we are indulged in exporting, manufacturing, supplying and trading for our premium quality coal ball mill machinery in Shanghai, China. All these products, we offer are manufactured from premium raw materials using innovative techn

Shanghai Clirik Machinery Co., Ltd.

Shanghai

Trusted Seller

Trusted Seller10 Years

Premium Seller

Premium SellerWhite Coal Making Machine

Product DescriptionSupported by vast business knowledge, we are indulged in exporting, manufacturing and supplying of White Coal Making Machine in Rajkot, Gujarat, India. Technically advanced White Coal Making Machines requires minimum maintenance and is durable. Our entire product range is corrosion resistant thereby

White Coal Machine

Product DescriptionFollowing are the Main Features of White Coal Machine: - Product Capacity: 1500 kg/hr 20 % depending on raw material size & its density. Finished Product Size: 90 mm Diameter Finished Product Shape : Cylindrical Process Cost/MT (Approx) : Indian Rs. 530 Approx. / MT Competitive Advantages of White

White Coal Briquette Machine

Product DescriptionWe are manufacturer of White Coal Briquette Machine, through this machine we can convert any type of agro waste into solid briquette form which is known as white coal/briquettes. These are also known as Agro Biomass Briquetting Plant, Agro Briquetting Press, Agro Coal Briquetting Plant

White Centrifugal Dehydrator For Fine Coal

MOQ1 Unit/Units

Colorwhite

Usage/Applicationsindustrial

Coal Sampling Machine

Product DescriptionOur company is the noteworthy names engaged in trading and supplying a superior quality range of Coal Sampling Machine in Korba, Chhattisgarh, India. Our offered machine is manufactured using the best grade components and advanced technology in adherence to the set industry standards. These machines

Automatic White Coal Making Machine

Payment TermsCheque, Others, Cash Against Delivery (CAD)

Main Domestic MarketAll India

Top Rated Products

FAQs Related to White Coal Machine

Who are the top white coal machine manufacturers in India?

- Jay Khodiyar Machine Tools

- Ronak Engineering

- Sigma Instrumentation

- Shanghai Clirik Machinery Co., Ltd.

- Confider Industries Llp

- Radhe Engineering Company

- Punjab Engineering Corporation

Which cities have the largest number of white coal machine suppliers?

- Ahmedabad

- Rajkot

- Indore

- Korba

- Zhengzhou

- Zhuzhou

What is the price range for white coal machine offered by listed companies?

| Company Name | Currency | Product Name | Price |

|---|---|---|---|

| PUNJAB ENGINEERING CORPORATION | INR | Fully Automatic Badami Coal Machine | 127500 |

| RONAK ENGINEERING | INR | White Coal Briquette Machine | 1790000 |

How many trusted sellers are available for white coal machine?

- CONFIDER INDUSTRIES LLP

- Radhe Engineering Company

- PUNJAB ENGINEERING CORPORATION

- SHANGHAI CLIRIK MACHINERY CO., LTD.

- Shree Khodiyar Engineering Works

- SIGMA INSTRUMENTATION

What is the minimum order quantity for white coal machine?

Do listed companies have registration & certifications?

- CONFIDER INDUSTRIES LLP

- JAY KHODIYAR MACHINE TOOLS

- Radhe Engineering Company

- SHANGHAI CLIRIK MACHINERY CO., LTD.

- RONAK AGROTECH ENGINEERING PVT. LTD.

- Global Agrotech Engineering

What is the get latest price feature?

What types of payment methods are accepted by the white coal machine suppliers?

White Coal Making Machine - Robust Design, Efficient Production Capacity | Expertly Manufactured Under International Quality Standards

Payment TermsCash Against Delivery (CAD)

Main Domestic MarketAll India

Hollow Coal Rod Machine

Product DescriptionOur organization hold expertise in providing superior grade Hollow Coal Rod Machine to our precious customers. Our offered Hollow Coal Rod Machine is widely appreciated by our customers, which are situated all round the nation. Known for its best quality, clients can avail this Hollow Coal Rod Machi

Efficient Coal Rod Machine (RYMBJ140)

Product DescriptionWe are instrumental in providing to our valuable customers excellent quality Efficient Coal Rod Machine (RYMBJ140) which is available with following specification:- Model:RYMBJ140 Power(KW): 11 Output(t-h): 1-2 Cross-section shape(mm): 20-30 Revolutions(rpm): 60 Diameter(mm): 120 Spiral number: 5 Di

Zheng Zhouruiyong Machinery And Equipment Limited Company

Zhengzhou

Lead, Magnesium, Coal Briquette Machine

Product DescriptionThese Lead, Magnesium, Coal Briquette Machine is suitable for civil and industrial coal production. It features in excellent technical performance, compact structure, reasonable assembly process, special alloy material rollers, and long life. It also solves the coal problems of low molding pressure

Gongyi Hengchang Metallurgy Building Material Equipment Plant

Zhengzhou

Coal Honeycomb Briquette Machine

Product DescriptionHSMQ SERIES Coal Honeycomb Briquette Machine is to make the block of compressed charcoal dust, coal powder, or sawdust and wood chips, used for fuel and kindling. The Raw Materials will by formed by the Punching needles of the machie and the final products have high density and easy to burn, long la

More details...

Sigma Instrumentation

Ahmedabad

Trusted Seller

Trusted Seller14 Years

Super Premium

Super PremiumMore details...

More details...

More details...

More details...

More details...

More details...

More details...

Latest from White Coal Machine

White Coal Machine Spare Parts

By:

Kranti Engineering

White Coal Machine

By:

Radhe Equipments India

White Coal Machine

By:

Ronak Agrotech Engineering Pvt. Ltd.

Agro Briquetting Machine

By:

Jay Khodiyar Machine Tools

Explore in hindi

सफेद कोयला मशीन

White coal machines are robustly designed machines that are used widely to produce white coal. The working method of the machines is that these receive the requisite raw materials and then press those at high load in an inbuilt feeder box through a simple mechanism using cylinder and a piston. The compression resulting from the exertion of high load extracts lignin( a glue like substance produced by wood at high temperature or pressure) that binds the raw materials together. The bounded materials are then dried over a fire or at very high temperature in an industrial oven, thus producing white coal.

White coal differs from carbonized coal and is also comparatively less polluting and cheaper to produce. White coal machines are high performance machines that can churn out large quantities of white coal with uniform size in a very short time. Furthermore, these are very easy to operate and generally contain no sharp edges, thus increasing the overall safety of people working around the white coal machines

White Coal Machines Can Make White Coal From :

Groundnut shells

Castor seed shells

Coir dust

Sunflower waste

Bajra cobs

Wheat straw

Mustard waste

Maize stalks

Rice husk

Features of White Coal Machines

These are resistant to corrosion and wear.

Also resistant to impacts.

The white coal machines are designed in such a way so as to ensure high fatigue tolerance.

These can operate flawlessly in all weather conditions.

These have minimal noise levels, thus eliminating any risk of hearing problems in people working around the machines.

Optimal tolerance to hoop stress.

Benefits of Coal Produced by White Coal Machines

The white coal has zero moisture content, thus ensuring optimal burning.

Also zero sulfur content ensuring no release of toxic gases.

The combustion of white coal is comparatively more uniform than carbonized coal or firewood.

Maintenance of White Coal Machines

Periodically the machines should be maintained with strict adherence to the guidelines given by white coal machine manufacturers.

The maintenance should only be done by qualified personnel.

If any part of the machine has become unusable, then only authentic part provided by a trusted vendor should be used as replacement.

Before maintenance, the machines should be cut off from any sort of power supply.

The removable parts of white coal machines should preferably be removed before maintenance. These can be easily installed again after the maintenance is complete.

Client Testimonials & Reviews

Govind Singh

FLEXITECH INDIA

We are the Manufacturers of CNC Routers, Plasma, Stealth, S2, Viper, PRO NBM, Cobra, XL, and XXL. We are the member of tradeindia since 2010. We are comfortable with tradeindia services. Wishing all the Best to tradeindia.

BalvinderSingh

SATNAMIA GEAR COMPANY

We are using Tradeindia from the last so many years and It is very useful and helpful for our business, and we are really grateful and thankful to the Tradeindia team. We are fully i.e. 100% satisfied with the Tradeindia.

SurenderSharma

KESHAV ENTERPRISES

Tradeindia is Very good application for Good inquiry and Better Promotion. Its useful for better B2B service. There is good inquiry.

SanjaySakhiya

RONAK ENGINEERING

It was difficult to find Buyers in this competitive world for our unique business, but well worth the wait. Wea ve worked with tradeindia.com now for several years and trust their team to meet our needs. Throughout their time with us. tradeindia.com has provided consistent quality solutions and service, helping our business to move forward.

VijayMaurya

MAURYA UDYOG

Being the Manufacturer of High Speed Shoe Lace Fully and semi Automatic Tipping Machine, Shoe Lace Waxing Machine and Spare parts, Semi and fully Automatic Tipping Machine for Carry Bags. We have been associated with tradeindia.com India's largest B2B Portal for last one year. I am using as a Marketing Tools. I Wish tradeindia team for Bright future.

SidharthGoel

KIRAN ENGINEERING COMPANY

I am satisfied with tradeindia.com services. Tradeindia is doing good to promote our company. Thank you.

SudershanChekuri

THREAD FORM MACHINE INDUSTRIES

We are satisfied with tradeindia.com. We are getting the business from it.

RajnishSanger

S. B. MACHINE TOOLS

I am associated with tradeindia from 8 years and we are having a very satisfactory response from them in our business expansion. We are very confidently look forward to a long-term relation with tradeindia for our sales and promotion in future also.

Mr.Deepak

SIDDHAPURA MACHINE TOOLS

We are happy to be member of Trade India since last five year and Trade India has helped us to increase our business internationally and domestic market and achieved pioneer name in the market. We thanks to trade India to be a one of the partner of our firm to grow our business with hand to hand.

GSharma

FLUIDOMATIC

We already associated with tradeindia. This has helped us to exponentially to expand our presence not only Domestically with in India but also in different International markets.

White Coal Machine Price List

Product Name | Expected Price |

|---|---|

| Fully Automatic Badami Coal Machine | 127500 |

| White Coal Briquette Machine | 1790000 |

This Data was Last Updated on 2024-12-14

White Coal Machine Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Jay Khodiyar Machine Tools Rajkot, India | 19 Years |

Ronak Engineering Rajkot, India | 18 Years |

Sigma Instrumentation Ahmedabad, India | 14 Years |

Shanghai Clirik Machinery Co., Ltd. Shanghai, China | 10 Years |

Confider Industries Llp Ahmedabad, India | 3 Years |

Radhe Engineering Company Rajkot, India | 1 Years |

Punjab Engineering Corporation Indore, India | 1 Years |

Upcoming Tradeshows

Gulfood 2025

Mon, 17 Feb, 2025 - Fri, 21 Feb, 2025

National Expo Raipur 2025

Sun, 19 Jan, 2025 - Wed, 22 Jan, 2025

International Crop Science Conference and Exhibition 2025

Tue, 21 Jan, 2025 - Wed, 22 Jan, 2025

LogiMAT India 2025

Thu, 13 Feb, 2025 - Sat, 15 Feb, 2025

WATER EXPO VIJAYAWADA 2025

Wed, 29 Jan, 2025 - Fri, 31 Jan, 2025

Printing South China 2025

Tue, 04 Mar, 2025 - Thu, 06 Mar, 2025

CHINA INTERNATIONAL FURNITURE FAIR 2025

Tue, 18 Mar, 2025 - Fri, 21 Mar, 2025

INDIA ART FESTIVAL 2024

Thu, 19 Dec, 2024 - Sun, 22 Dec, 2024

MachAuto 2025

Fri, 23 May, 2025 - Mon, 26 May, 2025

10th IMTOS-India Machine Tools Show 2025

Thu, 15 May, 2025 - Sun, 18 May, 2025

Popular Categories