- Tradeindia

- Industrial Supplies-General

- Mixing Tank

Mixing Tank

(382 products)Flavoured Mixing Tank Application: Industrial

Price: 50000 INR/Piece

MOQ5 , Piece/Pieces

UsageIndustrial

ConditionNEW

Capacity250-500 L Liter/day

Pharmaceutical Mixing Tanks - Application: Industrial

Price: 100000.00 INR/Set

MOQ1 Set/Sets

SizeStandard

Product TypeMixing Tanks

ColorSilver

Nu Pharma Engineers & Consultant

Ahmedabad

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller11 Years

Sunrise Process Equipments Private Limited

Mumbai

Trusted Seller

Trusted Seller21 Years

Super Seller

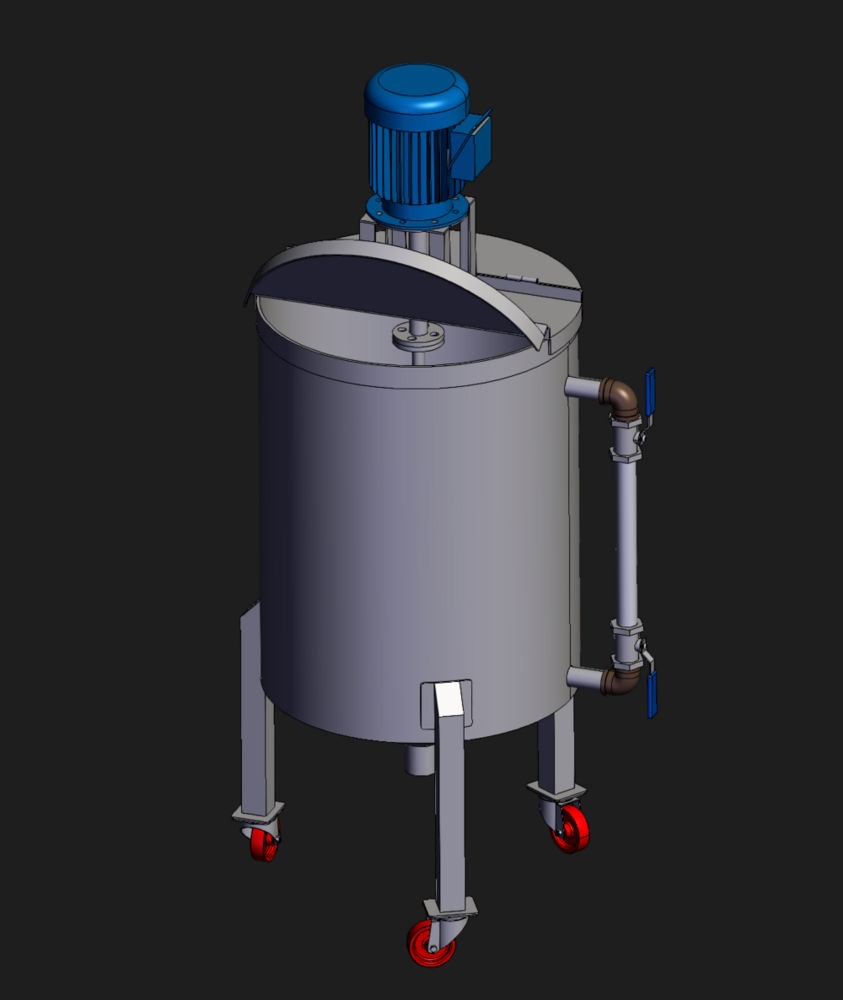

Super SellerBatch Mixing Tanks By Ved Engineering

Price: 210000.00 INR/Unit

MOQ1 Set/Sets

TypeOther, Pharmaceutical Equipment

MaterialStainless Steel

Capacity500-5000 Liter Liter/day

Silver Ss Mixing Tank With Agitator(Air Operated)

Price: 130000 INR/Piece

MOQ1 Piece/Pieces

Product TypeSS Mixing Tank With Agitator(Air Operated)

UsageCommercial

SizeStandard

Mixing Chamber - Finish: Polished

Price: 100000 INR/Unit

MOQ10 Unit/Units

FinishPolished

For Use InCommercial

MaterialStainless Steel

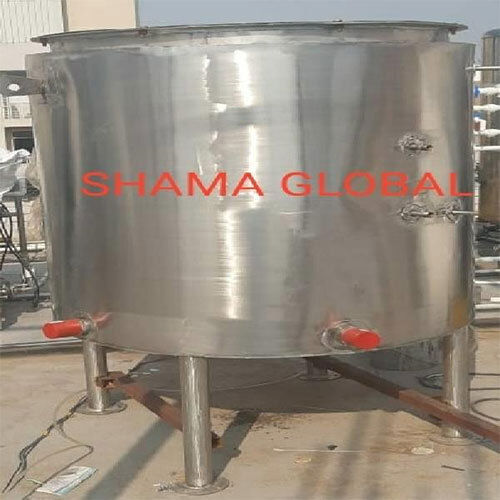

Ss Mixing Tank

Price: 150000.00 INR/Number

MOQ1 Number

Used ForChemical industry

ColorANY

Product TypeMIXING TANK

Reaction Dosing Tank

Price: 150000 INR/Unit

MOQ1 Unit/Units

Main Domestic MarketAll India

Floor Mounted Heavy-Duty Stainless Steel High Efficiency Electrical Mixing Tank

SizeStandard

Used ForFor Industrial

ColorSilver

Blacknut Agrifood Machinery Private Limited

Ambala

Trusted Seller

Trusted Seller3 Years

Super Seller

Super SellerPp Mixing Tank - Capacity: 10000-60000 Liter/Day

Price: 20000 INR/Unit

MOQ1 Unit/Units

UsageIndustrial

Size2000-3600 mm

MaterialStainless Steel

Industrial Poly Tanks And Vessels

Palghar

Trusted Seller

Trusted Seller13 Years

Super Seller

Super SellerMixing Tank - Color: Sliver

Price: 50000 INR/Unit

MOQ1 Unit/Units

ColorSliver

MaterialMetal

ComputerizedNo

Top Rated Products

Floor Mounted Heavy-Duty Stainless Steel High Efficiency Electrical Mixing Tank

Blacknut Agrifood Machinery Private Limited

FAQs Related to Mixing Tank

Who are the top mixing tank manufacturers in India?

- Sunrise Process Equipments Private Limited

- Spirall Plastics

- Industrial Poly Tanks And Vessels

- Pratham Engineering

- Darshit Trading Company

- Nu Pharma Engineers & Consultant

- Ved Engineering

- Zhejiang Meibao Industrial Technology Co., Ltd.

- D. K. Pharma Engineering

- Verma Process Pack

Which cities have the largest number of mixing tank suppliers?

- Mumbai

- Chennai

- Delhi

- Bengaluru

- Pune

- Kolkata

- Hyderabad

- Ahmedabad

- Vadodara

- Faridabad

- Gurugram

- Coimbatore

- Noida

- Ghaziabad

- Surat

- Indore

- Howrah

- Thane

- Secunderabad

- Ambala

What is the price range for mixing tank offered by listed companies?

| Company Name | Currency | Product Name | Price |

|---|---|---|---|

| CONCEPT FAB WORKS | INR | Stainless Steel Mixer | 98000 |

| M and T Engineering Equipment's | INR | Flavour Mixing Tank | 195000 |

| KARADANI ENGINEERING PRIVATE LIMITED | INR | Heavy Duty High Pressure Mixing Tank | 475000 |

| Aum Controls & Equipments | INR | SS Mixing Tank | 200000 |

| Galaxy Fabrication & Engg Works | INR | Capacity 2000-3000 Liter Stainless Steel Mixing Tank For Industrial | 150000 |

| V STAR PHARMA MACHINERY | INR | Stainless Steel Mixing Tank | 100000 |

| AM Industries | INR | Heavy Duty Mixing Tank | 8000 |

| CHARMI ENGINEERING | INR | Electric Heating Mixing Tank | 48000 |

How many trusted sellers are available for mixing tank?

- INNOVATIVE ENGINEERING WORKS

- NU PHARMA ENGINEERS & CONSULTANT

- SUNRISE PROCESS EQUIPMENTS PRIVATE LIMITED

- VED ENGINEERING

- SOARMLICH ENGINEER

- BHAVYA INDUSTRIES

- CHARMI ENGINEERING

- ULTRA FEBTECH PRIVATE LTD.

- BLACKNUT AGRIFOOD MACHINERY PRIVATE LIMITED

- VARADRAJ INDUSTRIES

- INDUSTRIAL POLY TANKS AND VESSELS

- KRVN MACHINERY

- PRATHAM ENGINEERING

- Zhejiang Meibao Industrial Technology Co., Ltd.

- SHRAJ MACHINERY

- SPIRALL PLASTICS

- ULTRAFAB ENGINEERS

- OMICRON EQUIPMENT PVT. LTD.

- Seven Seas Enterprise

- DARSHIT TRADING COMPANY

- AKSHAR ENGINEERING WORKS

- SHREE BHAGWATI MACHTECH (I) PVT. LTD.

- J B ENGINEERING AND HYDRULICS

- SHAMA GLOBAL

- Bhagya Laxmi Industries

What is the minimum order quantity for mixing tank?

Do listed companies have registration & certifications?

- NU PHARMA ENGINEERS & CONSULTANT

- SOARMLICH ENGINEER

- INDUSTRIAL POLY TANKS AND VESSELS

- OMICRON EQUIPMENT PVT. LTD.

- SHREE BHAGWATI MACHTECH (I) PVT. LTD.

- VERMA PROCESS PACK

What is the get latest price feature?

What types of payment methods are accepted by the mixing tank suppliers?

Mixing Tank Homogenizer Capacity: 1000-5000 Liter/Day

Price: 1500000 INR/Unit

MOQ1 , Unit/Units

Capacity1000-5000 Liter/day

ColorSliver

Product TypeMixing Tank Homogenizer

Detergent Line Mixing Tank Usage: Industrial

Price: 80000.00 USD ($)/Set

MOQ1 Set/Sets

ConditionNEW

Product TypeMixing Tank For Detergent Line

UsageIndustrial

Zhejiang Meibao Industrial Technology Co., Ltd.

Hangzhou

Trusted Seller

Trusted Seller11 Years

Premium Seller

Premium Seller200Ltr Stainless Steel Liquid Mixing Tank - Application: Industrial

Price: 150000 INR/Unit

MOQ1 Unit/Units

ConditionNEW

GradeIndustrial

Size200 L

Chemical Mixing Tanks

Payment TermsCheque

Supply AbilityAs per requirment Per Month

Main Domestic MarketAll India

Spirall Plastics

Navi Mumbai

Trusted Seller

Trusted Seller17 Years

Premium Seller

Premium SellerAutomatic Commercial Grade Milk Pasteurizer

Price: 430000.00 INR/Piece

MOQ1 Piece/Pieces

ColorSilver

TypeAutomatic

Product TypeMilk Pasteurizer

Automatic Dual Mixing Tank

MOQ1 Unit/Units

Product TypeOther, Dual Mixing Tank

Power SourceElectricity

Operating TypeAutomatic

Omicron Equipment Pvt. Ltd.

Ahmedabad

Trusted Seller

Trusted Seller1 Years

Premium Seller

Premium SellerPrecipitation Tank With Stirrer - General Use: Industrial

Price: 120000 INR/Unit

MOQ1 Unit/Units

General UseIndustrial

MaterialSteel Alloy

ComputerizedNo

Plastic Sintex Mixing Tank

Price Trend: 2600.00 - 3500.00 INR/Unit

MOQ10 Unit/Units

Product TypeSintex Mixing tank

UsageStorage

ColorBlack

Darshit Trading Company

Ahmedabad

Trusted Seller

Trusted Seller13 Years

Premium Seller

Premium SellerJacketed Mixing Tank Application: Industrial

Price: 100000 INR/Number

MOQ5 Number

Product TypeJACKETED MIXING TANK

ColorSilver

UsageIndustrial

Akshar Engineering Works

Chhatral

Trusted Seller

Trusted Seller5 Years

Premium Seller

Premium SellerSemi Contra Mixing Tank Capacity: As Per The Client Required Kg/Hr

Price Trend: 10 -90 INR/Piece

MOQ1 Piece/Pieces

TypePharmaceutical Packaging Machine

MaterialStainless steel

CapacityAs per the Client required Kg/hr

Shree Bhagwati Machtech (i) Pvt. Ltd.

Ahmedabad

Trusted Seller

Trusted Seller5 Years

Premium Seller

Premium SellerSS Mixing Tank

Product DescriptionAs a chief entity, we are manufacturing, exporting and supplying an extensive array of SS Mixing Tank in Indore, Madhya Pradesh, India. At our advanced production unit, the offered tank is manufactured by our ingenious professionals with the utilization of stainless steel and cutting edge techniques

Steel Special Slurry Tank Mixing System

MOQ100 Piece/Pieces

SizeAs per requirement

UsageIndustrial

MaterialSteel

J B Engineering And Hydrulics

Korba

Trusted Seller

Trusted Seller1 Years

Premium Seller

Premium SellerAutomatic 12Kltr Mixing Tank

Price: 875000 INR/Piece

MOQ1 Piece/Pieces

TypeMixing Kettle

MaterialStainless Steel

ComputerizedNo

Ss Ms Tank Application: Juice Plant

Product TypeTANK

Width1500 Millimeter (mm)

ColorSteel

Silver 500 L Stainless Steel Liquid Mixing Tank

Price: 1,10,000 INR/Unit

MOQ1 Unit/Units

Sizecustomized

ApplicationMixing tank

UsageIndustrial

Bhagya Laxmi Industries

New Delhi

Trusted Seller

Trusted Seller1 Years

Premium Seller

Premium SellerLatest from Mixing Tank

Stainless Steel High Pressure Capacity CSTR mixing tank 1000 liters chemical reactor

By:

Jct Machinery Co., Ltd

Jacketed Mixing Tank-Vessel With Stirrer

By:

Avishkar Technology

Mixing Tank for Quality Product Development

The food, chemicals, medicines, and cosmetics businesses always need of mixing raw materials. Hence, the mixing tank is the ideal choice for many industries to mix materials. It is made of many components like sensors, heating or cooling jackets, baffles, agitators, and inlets or outputs which play an important role in producing high-quality products. It ensures consistent and uniform product development. Manufacturers develop the mixing tanks according to the demands and requirements. It is available in different types like batch, continuous, and sanitary mixing tanks. Each mixing tank has unique properties to meet the demand of consumers' businesses.

Benefits

-

Mixing tanks allow maintenance of the homogeneity in the mixing of raw materials in industrial products. It is used for industries like pharmaceuticals, food, chemicals, and cosmetics. It makes the product consistent and quality for perfect use.

-

Mixing tanks helps to increase the efficiency of business for better output. It saves more time and reduces the involvement of many labor to perform the task. It involves a reduction in time and improves business operations.

-

Mixing tanks are used to scale the performance of the business. It comes in different sizes and helps to prepare the mixture from small batches to large batches. It helps to perform the task with flexibility and adds more functional output.

-

It allows one to maintain precise control over the temperature of the blended mixture. Some chemical products are required for specific thermal conditions to develop the quality of the product.

-

It shows versatility in handling different types of materials like liquids, solids, and gasses. It provides perfect blending or mixing to process the different types of industrial materials.

-

It is equipped with advanced features and controlled operations to reduce the wastage of material. It helps to reduce the cost of wastage and the impact on the environment.

Features

-

Volume

The capacity of the mixing tank depends upon the requirements of the business. It is available in different sizes and for every type of industry.

-

Temperature

The mixing tank is equipped with proper control to allow for required heating or cooling to circulate in the vessel.

-

Plumbing System

It has a perfect input and output plumbing system for the further processing of the mixture.

-

Sealing

It has perfect sealing through the gap between the shaft and the wall of the tank. It prevents the leaking of the mixture from the tank.

-

Beater System

Mixing tanks have paddles to suck the mixture from the bottom of the tank and deposit at the top.

-

Material

The material of the mixing tank must be made up of stainless steel. It allows the material to resist corrosion and rust.

-

Easy to Clean

Mixing tanks have a properly installed pipe system to provide the proper cleaning facility.

Applications

-

A mixing tank is used to mix the pharmaceutical ingredients to produce tablets, syrups, vaccines, ointments, and other sterile solutions. Medicines require a precise and consistent mix of formulations. It helps to maintain the quality of pharmaceutical products.

-

A good mix of ingredients, powders and to maintain the uniformity of food products. It’s used for the production of sauces, dressings, salsa, jam, peanut butter, chocolate, dairy products, beverages, soups, and other food products.

-

It helps to produce the right mix of perfect chemicals required for industrial applications. It helps to blend the chemicals, create emulsions, and to produce the chemical reactions. It’s required to prepare the products like paints, solvents, detergents, adhesives, and many industrial chemical products. It maintains the proper consistent product for the maintenance of the industrial application.

-

In the petrochemical industry, it is used to produce different types of petroleum products. It helps to produce products like fuels, lubricants, additives, and some specialty chemicals like surfactants and solvents.

-

A mixing tank blends the ingredients of products like lotion, facial cream, nail polish, shampoos, conditioners, and other cosmetic products. It improves the standard of the product with the required texture, consistency, and quality.

-

A mixing tank is used to blend the chemicals required to treat the wastewater stream. It is used in municipal wastewater and industrial effluent. It helps to produce biofuels and other renewable energy sources.

Types

-

Tank Mixers

Tank mixer is ideal for smaller production-size batches and large tanks for low-viscosity material for gentle mixing. Tank mixers are available at different scales, power options, and batch volumes. It is produced for rigid mounts with perfect sealing or pressurized systems. It is available in a wide range of tank mixer models and can be customized according to business.

-

Sanitary Mixers

Sanitary Mixers are designed to prevent contamination and ensure the safety of products. It’s an ideal mixing tank for industries like pharmaceuticals, cosmetics, food & beverages. It helps to maintain the proper government standards to help customers to produce safe and hygienic products. It is essential for industries that require strict sanitary and hygienic standards.

-

Drum Mixers

The Drum Mixer is the most common type of mixing tank available from the manufacturing unit. It is required for the production and distribution of liquid products. It maintains the requirements of industries like power source, type of material, and type of liquid like viscous or non-viscous.

-

Laboratory Mixers

Lab Mixers are used to agitate and mix the different samples. It consists of an oscillating, motorized platform, designed to hold flasks, beakers, or tubes. It has inbuilt features like removable mixing shafts, interchangeable impellers, digital controller for speed control. It helps to maintain the quality of the product with a uniform mixture.

-

Handheld Mixers

A handheld mixer is for small-batch mixing with the use of a hand-held drill. It is a portable equipment with electrical connectivity used to combine small batches of ingredients. It has removable beaters and other attachments. It is useful for industries like food and beverage, water purification, and chemicals.

-

Closed-Container Mixers

A closed-container mixer is used to process in a closed container to reduce the problem of contamination and allow for easy cleaning. It is built with a variety of mixing motions to produce a homogeneous product without opening the lid.

Client Testimonials & Reviews

ArnavMahapatra

RUEDO ENGINEERING

We are very happy to inform that I am associated with tradeindia since long. I must say it's a good organization and I am happy with their service.

Mixing Tank Price List

Product Name | Expected Price |

|---|---|

| Stainless Steel Mixer | 98000 |

| Mixing Tank | 98000 |

| Flavour Mixing Tank | 195000 |

| Heavy Duty High Pressure Mixing Tank | 475000 |

| SS Mixing Tank | 200000 |

| Capacity 2000-3000 Liter Stainless Steel Mixing Tank For Industrial | 150000 |

| Stainless Steel Mixing Tank | 100000 |

| Heavy Duty Mixing Tank | 8000 |

| Electric Heating Mixing Tank | 48000 |

| Flavoured Mixing Tank | 125000 |

This Data was Last Updated on 2024-12-13

Mixing Tank Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Sunrise Process Equipments Private Limited Mumbai, India | 21 Years |

Spirall Plastics Navi Mumbai, India | 17 Years |

Industrial Poly Tanks And Vessels Palghar, India | 13 Years |

Pratham Engineering Mira Bhayandar, India | 13 Years |

Darshit Trading Company Ahmedabad, India | 13 Years |

Nu Pharma Engineers & Consultant Ahmedabad, India | 11 Years |

Ved Engineering Noida, India | 11 Years |

Zhejiang Meibao Industrial Technology Co., Ltd. Hangzhou, China | 11 Years |

D. K. Pharma Engineering Indore, India | 10 Years |

Verma Process Pack Delhi, India | 7 Years |

Upcoming Tradeshows

Gulfood 2025

Mon, 17 Feb, 2025 - Fri, 21 Feb, 2025

National Expo Raipur 2025

Sun, 19 Jan, 2025 - Wed, 22 Jan, 2025

International Crop Science Conference and Exhibition 2025

Tue, 21 Jan, 2025 - Wed, 22 Jan, 2025

LogiMAT India 2025

Thu, 13 Feb, 2025 - Sat, 15 Feb, 2025

WATER EXPO VIJAYAWADA 2025

Wed, 29 Jan, 2025 - Fri, 31 Jan, 2025

Printing South China 2025

Tue, 04 Mar, 2025 - Thu, 06 Mar, 2025

CHINA INTERNATIONAL FURNITURE FAIR 2025

Tue, 18 Mar, 2025 - Fri, 21 Mar, 2025

INDIA ART FESTIVAL 2024

Thu, 19 Dec, 2024 - Sun, 22 Dec, 2024

MachAuto 2025

Fri, 23 May, 2025 - Mon, 26 May, 2025

10th IMTOS-India Machine Tools Show 2025

Thu, 15 May, 2025 - Sun, 18 May, 2025

Popular Categories