- Tradeindia

- Bushings & Bushing Parts

- Bronze Bushes

Bronze Bushes

(438 products)Bronze Bushes Height: 20-1000 Millimeter (Mm)

21000 INR/, Piece

MOQ50 , Piece/Pieces

Width20-1000 Millimeter (mm)

Size20-1000MM

Height20-1000 Millimeter (mm)

Bronze Bush - Bore Size: 2 To 4 Inch

Price: 5 INR/Piece

MOQ5000 Piece/Pieces

Product TypeBronze Bush

UsageIndustrial

ColorBlack

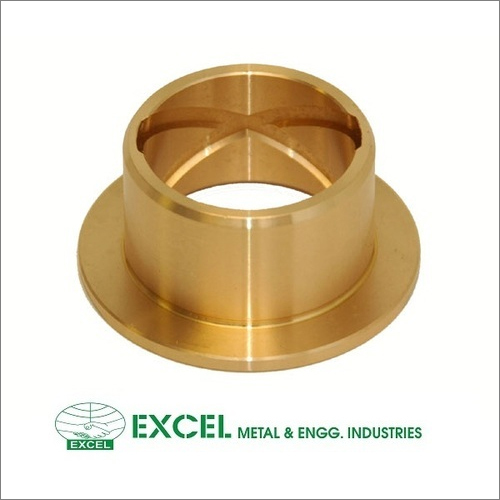

Ca 104 Aluminum Bronze Bushes - Color: Golden

Price: 400.00 INR/Kilograms

MOQ500 Kilograms/Kilograms

ColorGolden

Product TypeBushes

UsageIndustrial

Govind Metal Co.

Ahmedabad

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller17 Years

BUSHES ESCORTS

Price: 200 INR/Piece

MOQ200 Piece/Pieces

Product DescriptionBUSHES ESCORTS

Non Ferrous Aluminum Bronze Bushes

Price Trend: 50.00 - 500000.00 INR/Piece

MOQ1 Piece/Pieces

MaterialBRONZE

StructureNON FERROUS

Submersible Bronze Bushing Bore Size: Different Size

Price: 400 INR/Piece

MOQ50 Millimeter/Millimeters

MaterialBRONZE

Ball Bearing TypeOther

Roller Bearing TypeOther

Polished Bronze Gunmetal Bushes

Price: 650 INR/Kilograms

MOQ100 Kilograms/Kilograms

UsageIndustrial

TypeOther

MaterialBronze Gunmetal

Aluminium Bronze Bushing Application: For Industrial Use

Price Trend: 400.00 - 800.00 INR/Piece

MOQ10000 Piece/Pieces

Product TypeAluminium Bronze Bushing

ApplicationFor Industrial Use

Surface TreatmentPolished

Bhargav Brass Industries

Jamnagar

Trusted Seller

Trusted Seller13 Years

Premium Seller

Premium SellerBrass Bush Bronze Bushing Application: Industrial

MOQ100 Kilograms/Kilograms

ApplicationIndustrial

Product TypeBrass Round Inserts

ColorGolden

Polite Brass Industries

Jamnagar

Trusted Seller

Trusted Seller8 Years

Premium Seller

Premium SellerNickel Aluminum Bronze Bushes

Price: 1 INR/Piece

MOQ1 , Piece/Pieces

Supply Ability1 Per Day

Delivery Time1 Days

Shree Extrusions Limited

Jamnagar

Trusted Seller

Trusted Seller16 Years

Premium Seller

Premium SellerShree Extrusion Ltd.

Jamnagar

Trusted Seller

Trusted Seller10 Years

Premium Seller

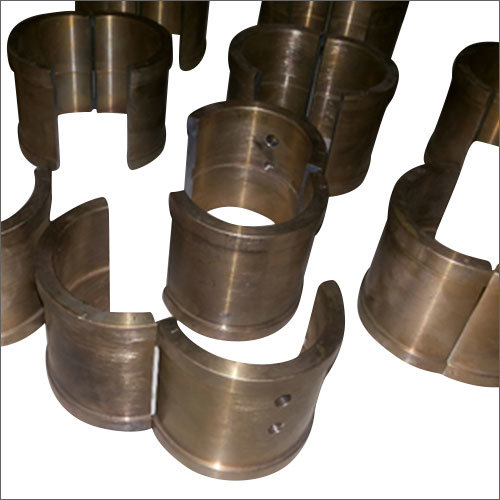

Premium SellerPolished Bronze Half Bush

Price Trend: 300.00 - 500.00 INR/Piece

MOQ100 - 150 Number

Weightas per drawing Grams (g)

Sizeas per customers requirement

Product TypeMechanical Bushes

Dhatvik India Private Limited

Nagpur

Trusted Seller

Trusted Seller4 Years

Premium Seller

Premium SellerTop Rated Products

FAQs Related to Bronze Bushes

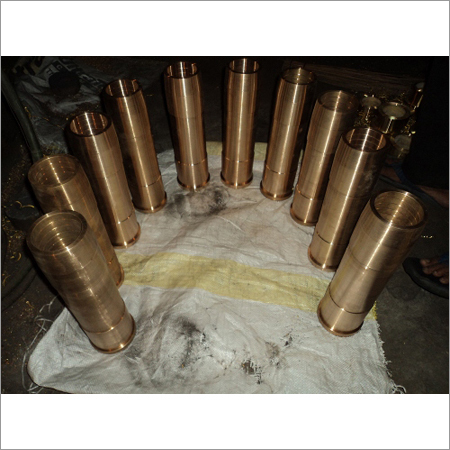

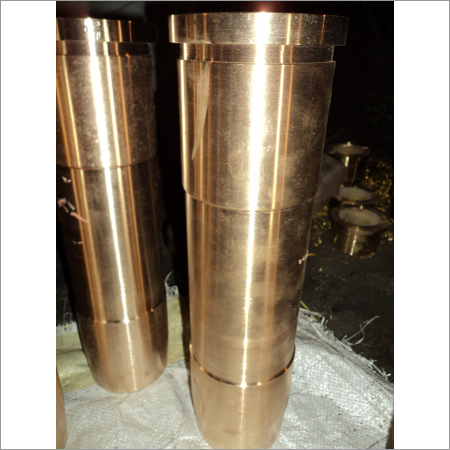

Earth Moving Bronze Bushing

Product DescriptionWe are reliable company indulged in manufacturing, exporting and supplying an excellent quality Earth Moving Bronze Bushing to our sensible customers in Rajkot, Gujarat, India. Known for their best quality. Also available in numerous sizes. our customers can avail this from us at reasonable price.\

Bronze Clin Bush

Price Trend: 70000.00 - 100000.00 INR/Piece

MOQ1 , Piece/Pieces

MaterialOther

Surface TreatmentGalvanized

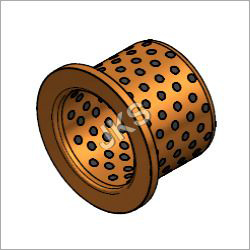

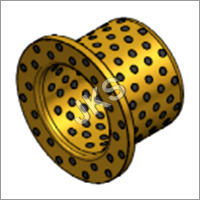

Bronze Bushes Warranty: 1 Year

Price Trend: 1500-2500 INR/Piece

MOQ100 Piece/Pieces

MaterialBronze

Bushes TypeFlanged

Warranty1 Year

Sintered Bronze Bush

Price Trend: 2.00 - 50.00 INR/Piece

MOQ2000 Piece/Pieces

Supply Ability10000 Per Week

Delivery Time30 Days

Packaging DetailsExport Quality Corrugated Box Packing

Golden Aluminium Bronze Bush

Price Trend: 250.00 - 1000.00 INR/Piece

MOQ10 Piece/Pieces

Product TypeAluminium Bronze Bush

ColorGolden

Weight50-100 Grams (g)

Kamaldeep Metal Works Pvt Ltd

New Delhi

Trusted Seller

Trusted Seller14 Years

Premium Seller

Premium SellerSubmersible Pump Bushes

Price Trend: 30-30000 INR/Piece

MOQ100 Piece/Pieces

Supply Ability2000 Per Week

Delivery Time1 Week

Aluminium Bronze Bushes - Finish: Polished

Price: 900 INR/Kilograms

MOQ50 Kilograms/Kilograms

Product TypeAluminium Bronze Bushes

UsageIndustrial

Length180 Millimeter (mm)

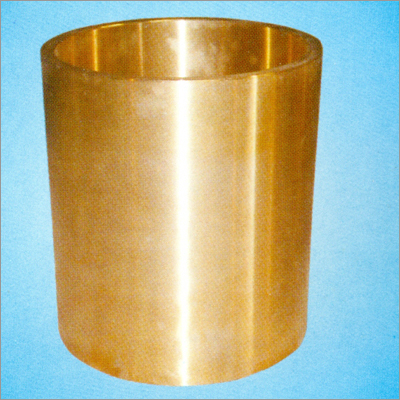

Bronze Bushes

Price: 500 INR/Piece

MOQ10 , Piece/Pieces

Supply Ability20 Per Day

Delivery Time3 Days

Aluminum Bronze Bushes

Price: 100.00 INR/Piece

MOQ1000 Unit/Units

Supply Ability10000 Per Day

Delivery Time1 Days

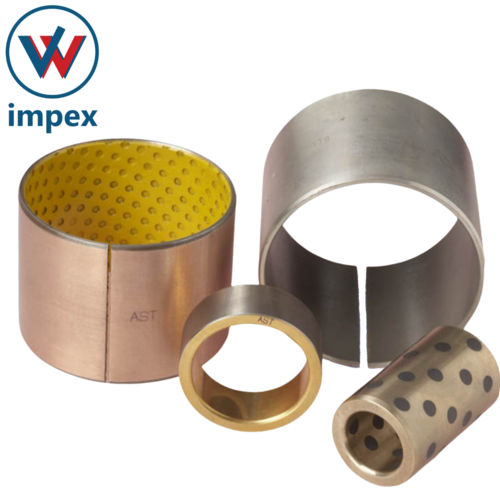

Bronze Alloy Self Lubricating Bearing Bore Size: As Per Requirement

Price Trend: 150.00 - 15000.00 INR/Piece

MOQ10 Piece/Pieces

WeightAs per standard Kilograms (kg)

SizeAs per requirement

LengthAs per requirement Millimeter (mm)

Silver Lift Machine Bronze Bushes

Price: 900 INR/Unit

MOQ10 Unit/Units

UsageIndustrial

ColorSilver

SizeDifferent Size

Self Lubricating Bushings

Price: 500 INR/Piece

MOQ6 Piece/Pieces

Product DescriptionSelf Lubricating Bushings

Jcb Bush Part No-176

Price: 410 INR/Kilograms

MOQ50000 Rs Kilograms/Kilograms

Delivery Time7-10 Days

Brown Tanishq Graphite Filled Bronze Bushes

Price: 600.00 INR/Kilograms

MOQ1 Kilograms/Kilograms

ColorBrown

Weight1 Kilograms (kg)

Product TypeGraphite Bronze Bush

Latest from Bronze Bushes

What are Bronze bushes

In order to properly provide a bearing surface for particular rotational applications, a bushing is a type of bearing that is often installed inside the housing. This specific kind of bearing can increase an operation's effectiveness. It often has a tube or sleeve shape, which reduces energy consumption, noise, and wear.

Bronze is one material that is frequently used to make bushings. Copper, tin, and other elements that contribute to the material's overall composition and physical characteristics are combined to form the alloy known as bronze. Bronze components and goods typically have excellent properties like resistance to corrosion and high/low temperatures, high ductility, and reasonable strength.

The strongest copper-based bearing alloys are aluminium bronzes. They are the only bearing bronzes that can be heat treated and exhibit greater strength at high temperatures. Manganese bronzes combine extremely high strength with significant corrosion resistance.

Primary Advantages of Bronze Bushings

Due to the properties of bronze, bushes made from this material can undoubtedly benefit a wide range of applications.

The exceptional corrosion resistance of bronze bushings is one of their many advantages. Bushings and bearings are often exposed to corrosive substances in many applications. The performance and overall operation of an industry could suffer if the wrong bushing material is chosen. Fortunately, bronze bushings can withstand corrosion because they have an extra layer of protection that prevents corrosive substances from penetrating.

The ability of bronze bushes to operate at high temperatures gives them a further advantage over other materials. They are more effective at transferring heat than most steels.

Primary Applications for Bronze Bushes

Sintered bronze or cast bronze can be used to manufacture bronze bushes. Applications involving both high and low speeds are often where oil impregnated bronze bushes made from sintered bronze perform best. These bushes are also suitable for high and low temperature applications.

Bronze bushes can also be made more corrosion resistant by using cast bronze as an alternative. Bronze bushes can be made more suitable for humid conditions and environments by using cast bronze.

Bronze bushes are commonly used in construction equipment, small electric motors, agricultural machinery and marine propellers. Iron and steel manufacturing, food processing and automotive are three industries that make the most of the benefits and features of bronze bushes.

Different Types of Bronze Bushes

The following are two typical bronze bushing materials and their applications:

- Oilite: Powder metallurgy formed bronze bushings impregnated with oil. Applications can include high and low speed machinery, high and low temperature machinery and food grade applications depending on the type of oil used.

- Copper: Often made from bronze and tin, aluminium or silicon, these alloys have high corrosion resistance, making them ideal for marine applications.

Other Types

- Metal and Bronze Bushes: Bronze bushes are normally made from continuously cast bronze to ensure a homogeneous construction. They are general purpose bushings that can withstand high temperatures (up to 450°F) and have good load carrying and anti-wear properties. To improve their performance, metal bushings can also be manufactured from various metals or alloys such as steel or stainless steel, brass, aluminium and copper.

- Plastic Bushings: Solid plastic bushes are widely used due to their light weight and corrosion resistance. Previous problems with heat sensitivity, softening, wear or shortened life at high temperatures can be solved with modern plastics. They work well in wet or humid situations, such as the dry kiln cartwheels used in lumber drying kilns, where the water lubricates the bushing. Despite its widespread use, plastic is not the recommended bushing material for heavy loads. If incorrectly manufactured or assembled, especially when using off-the-shelf bushes, it has a tendency to crack under heavy loads and misalignment is common. Polytetrafluoroethylene (PTFE) is the preferred engineering plastic when plastic is specified.

Use of Bronze bushes

Sintered bronze or cast bronze can be used to manufacture bronze bushes. Applications involving both high and low speeds are often where oil impregnated bronze bushes made from sintered bronze perform best. These bushes are also suitable for high and low temperature applications.

Bronze bushes can also be made more corrosion resistant by using cast bronze as an alternative. Bronze bushes can be made more suitable for humid conditions and environments by using cast bronze.

Bronze bushes are commonly used in construction equipment, small electric motors, agricultural machinery and marine propellers. Iron and steel manufacturing, food processing and automotive are three industries that make the most of the benefits and features of bronze bushes.

Client Testimonials & Reviews

MrNilesh

BAJRANG BRONZE LLP

We are the leading manufacturers for Bronze Bushes and Brass Bushes, Rajkot and have approved the service rendered by tradeindia.com for our brands good promotion in Domestic as well as in International markets. We are getting more and more coverage in this Global World through their services like call me free, many more. We are proud to be associated since last five years with them and we are totally satisfied with their services. Also their CRM Support given by them regularly. We are thankful for the support and hope it will continue years after years. Best Luck.

ManishDadhania

PRECISION SINTERED PRODUCTS

We have been associated with Tradeindia since last 14 years. We had a very good experience with Tradeindia and their staff, regarding promotion and business expansion of our company. We will have long lasting relationship with tradeindia in future also. I have recommended Tradeindia.com B2B portal to all my friends.

Bronze Bushes Price List

Product Name | Expected Price |

|---|---|

| Bronze Bush | 150 |

| Bronze Bush | 1300 |

| Bronze Bushes | 1200 |

| Bronze Bush | 350 |

| Bronze Bushes | 980 |

| Bronze Bush | 1500 |

| Lift Machine Bronze Bushes | 900 |

| Industrial Bronze Bush | 1100 |

| Aluminum Bronze Bushes | 1100 |

| Aluminium Bronze Bush | 1600 |

This Data was Last Updated on 2024-12-13

Bronze Bushes Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Spring India Mumbai, India | 24 Years |

Precision Sintered Products Rajkot, India | 21 Years |

Govind Metal Co. Ahmedabad, India | 17 Years |

Shree Extrusions Limited Jamnagar, India | 16 Years |

Kamaldeep Metal Works Pvt Ltd New Delhi, India | 14 Years |

Goyal Automotives New Delhi, India | 13 Years |

Bhargav Brass Industries Jamnagar, India | 13 Years |

Alloy & Alloy Products Howrah, India | 13 Years |

Raj Metal Industries Ahmedabad, India | 13 Years |

Spark Enterprises Pune, India | 12 Years |

Upcoming Tradeshows

Gulfood 2025

Mon, 17 Feb, 2025 - Fri, 21 Feb, 2025

National Expo Raipur 2025

Sun, 19 Jan, 2025 - Wed, 22 Jan, 2025

International Crop Science Conference and Exhibition 2025

Tue, 21 Jan, 2025 - Wed, 22 Jan, 2025

LogiMAT India 2025

Thu, 13 Feb, 2025 - Sat, 15 Feb, 2025

WATER EXPO VIJAYAWADA 2025

Wed, 29 Jan, 2025 - Fri, 31 Jan, 2025

Printing South China 2025

Tue, 04 Mar, 2025 - Thu, 06 Mar, 2025

CHINA INTERNATIONAL FURNITURE FAIR 2025

Tue, 18 Mar, 2025 - Fri, 21 Mar, 2025

INDIA ART FESTIVAL 2024

Thu, 19 Dec, 2024 - Sun, 22 Dec, 2024

MachAuto 2025

Fri, 23 May, 2025 - Mon, 26 May, 2025

10th IMTOS-India Machine Tools Show 2025

Thu, 15 May, 2025 - Sun, 18 May, 2025

Popular Categories