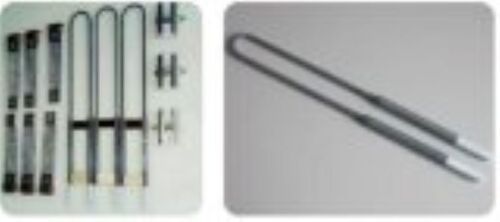

Molybdenum Disilicide Mosi2 Heating Element - 1.5 Kg, Grey, Round Shape | High-temperature Oxidation-resistant Element For Sintering And Heat Treatment Applications

Price:

Get Latest Price

In Stock

Product Specifications

| Color | Grey |

| Size | As your request |

| Product Type | Molybdenum Disilicide MoSi2 Heating Element |

| Usage | Sintering and heat treatment of ceramics, magnet, glass, metallurgy, refractory, etc. |

| Weight | 1.5 Kilograms (kg) |

| Insulation Material | Yes |

| Shape | Round |

| FOB Port | DALIAN |

| Payment Terms | Telegraphic Transfer (T/T), Western Union, Others |

| Supply Ability | 10000000 Per Year |

| Delivery Time | 15 Days |

| Sample Policy | Free samples available with shipping and taxes paid by the buyer |

| Packaging Details | Plywood case |

| Main Export Market(s) | Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa |

| Main Domestic Market | All India |

| Certifications | factory certification |

Product Overview

Key Features

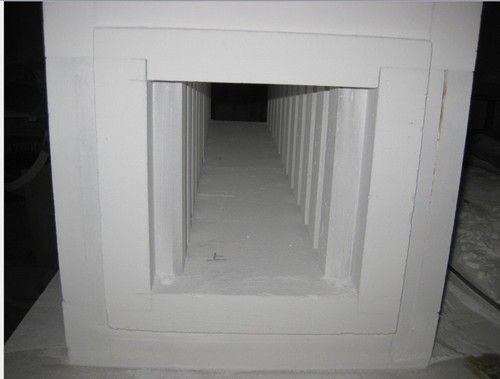

Having the same mechanical character as other ceramic products , MOSI2 heating elements are brittle materials so that they are easy to rupture at the normal temperature , which brings some difficulties to transport and install , but it may be avoided if they were installed and used correctly .

CHEMICAL PROPERTIES

Oxygen -resistance under high temperature : in oxidizing atmosphere , a layer of compact quarts (sio2) protective film is formed on the surface of element owing to the high -temperature combustion , which prevent MOSI2 from continuously oxidizing .When he element temperature is higher than 1700 degree. the sio2 protective film will be fused because its fusing point is 1710 degree celsius and the sio2 is fused into molten drop a owing to the action of its surface extension, which cause losing its protective ability . In the oxidizing atmosphere, when the element is continuously used , the protective film forms again .

It should be point out that element cannot be used for rather longtime in 400-700 degree celsius . otherwise it will be powdered owing to the strong oxidizing action in low temperature .

USAGE :

MoSi2 heating element can usually make use of furnace temperature from 1300 degree celsiusto 1800 degree celsius It is extensively used in the industries of metallurgy, glass, ceramic refractory, crystal electronic device, industrial furnace manufacture, etc.. It is an essential ideal element when the products are sintering in the high temperature

Advantage

Mosi2 heating element can quickly form a thin and adhesive anti-oxidizing layer of quartz glass(Sio2), under the high temperature oxidizing condition. If the protective layer was damaged, the element can reform a new one, so Mosi2 heating element has a very good anti-oxidation properties, it also means that the heating element can be used on operation for a much longer time than the traditional one.

Company Details

we provide sic heater mosi2 heater silicon carbide tube graphite sagger graphite heater exhibition carpet rib carpet bathroom carpet pvc floor

Business Type

Exporter, Manufacturer, Supplier

Employee Count

100

Establishment

1997

Working Days

Monday To Friday

Payment Mode

Telegraphic Transfer (T/T)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Liaoyang, Liaoning

Accepts only Domestic inquiries

Ceo

Mr Bai Ye David

Address

No.231, Zhonghua Street, Liaoyang, Liaoning, 111000, China

molybdenum heating element in Liaoyang

Report incorrect details