Dispersing Agent Anjeka 6110 For Solvent-borne And Solvent-free Coatings And Printing Inks, Stabilizes Inorganic Pigments, Especially Titanium Dioxide

Price:

Get Latest Price

In Stock

Product Specifications

| Chemical Name | Dispersing agent |

| Other Names | Dispersant |

| Type | Dispersant |

| Application | Coating and ink |

| Shelf Life | 2 Years |

| Payment Terms | Paypal, Telegraphic Transfer (T/T), Western Union |

| Supply Ability | 3000 Per Year |

| Delivery Time | 10 Days |

| Sample Policy | Within a certain price range free samples are available |

| Main Export Market(s) | Asia, South America, Middle East |

| Main Domestic Market | All India |

Product Overview

Key Features

Wetting and dispersing agent for solvent-borne and solvent-free coatings and printing inks, stabilizes inorganic pigments, especially titanium dioxide. Significantly reduces the viscosity

of abrasives.

PRODUCT DATA

Chemical composition: Copolymer solution with acidic groups. Typical physical and chemical data:

The data given on this data sheet are typical values and are not technical specifications of the

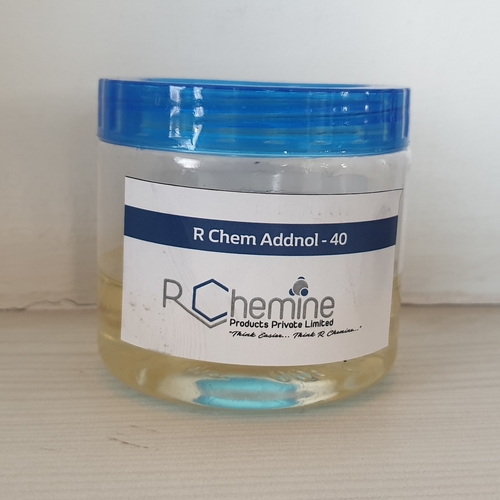

product. Appearance: Water-white to light yellow liquid

Acid value (mg KOH/g) 50-80

Density g/cmA (23a ) 0.90-1.10

Viscosity cps (25a ) 5-250

Active ingredient (%) 50

Solvent Triethylene glycol butyl ether/xylene (1:3)

STORAGE and TRANSPORT

Please stir well before use, if the temperature is lower than 0a , the oil may be layered or

muddy, heat to 30a -40a and stir well. Storage time is not recommended to exceed 12 months. SPECIAL NOTES

Due to the high acid value of the product, it may catalyze the cross-linking of the baking paint

system. Viscosity rise during storage of the paint system should be checked. APPLICATION GUIDELINES

Coating industry and printing inks

Properties and Advantages:

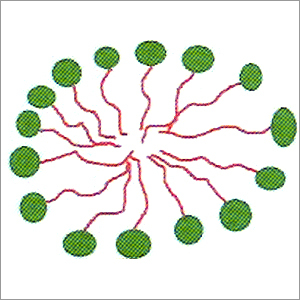

The additive unflocates and stabilizes the pigments by means of spatial site resistance. Due to

U

p

d a t e d 1 1 . 2 0 2

4

This information is provided to the best of our knowledge. Due to the many different formulations, production and

application conditions, all statements above must be adjusted to the actual situation of the processor, and we cannot make warranties, including patent rights, for individual cases. This

the small size of the deflocculated pigment particles, multi-color pigmented systems are

prevented from color floating and blooming. This results in increased gloss, color strength, transparency, and hiding power. The additive reduces viscosity. The additive reduces viscosity, thus improving flow and

allowing for higher pigment additions. When used for electrostatic high speed spin coating of

inorganic pigments, it significantly reduces haze.

APPLICATION SECTORS

This additive is recommended for stabilizing inorganic pigments, especially titanium dioxide, in solvent-borne and solvent-free coatings as well as in printing inks. Due to its anionic

character it is ideal for acid-catalyzed systems (e.g. coil coatings).

RECOMMENDED LEVELS

The amount of additive (in purchased form) is based on the pigment:

Titanium dioxide: 2%-4%

Inorganic pigments: 5%-10

The above data are empirical, the optimum dosage should be determined by a series of tests. INCORPORATION AND PROCESSING INSTRUCTIONS

In order to obtain the best performance, the additives should be added to the abrasive before

the pigments.

PACKAGING

-25kg iron drum with inner coating

-200kg ring plastic drum

Related Products

Explore Related Categories

More Product From This seller

Report incorrect details